Tire making machine

A tire building machine and tire technology, applied in tires, building types, building components, etc., can solve problems such as dirty beam environment, complex engineering, and rising manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

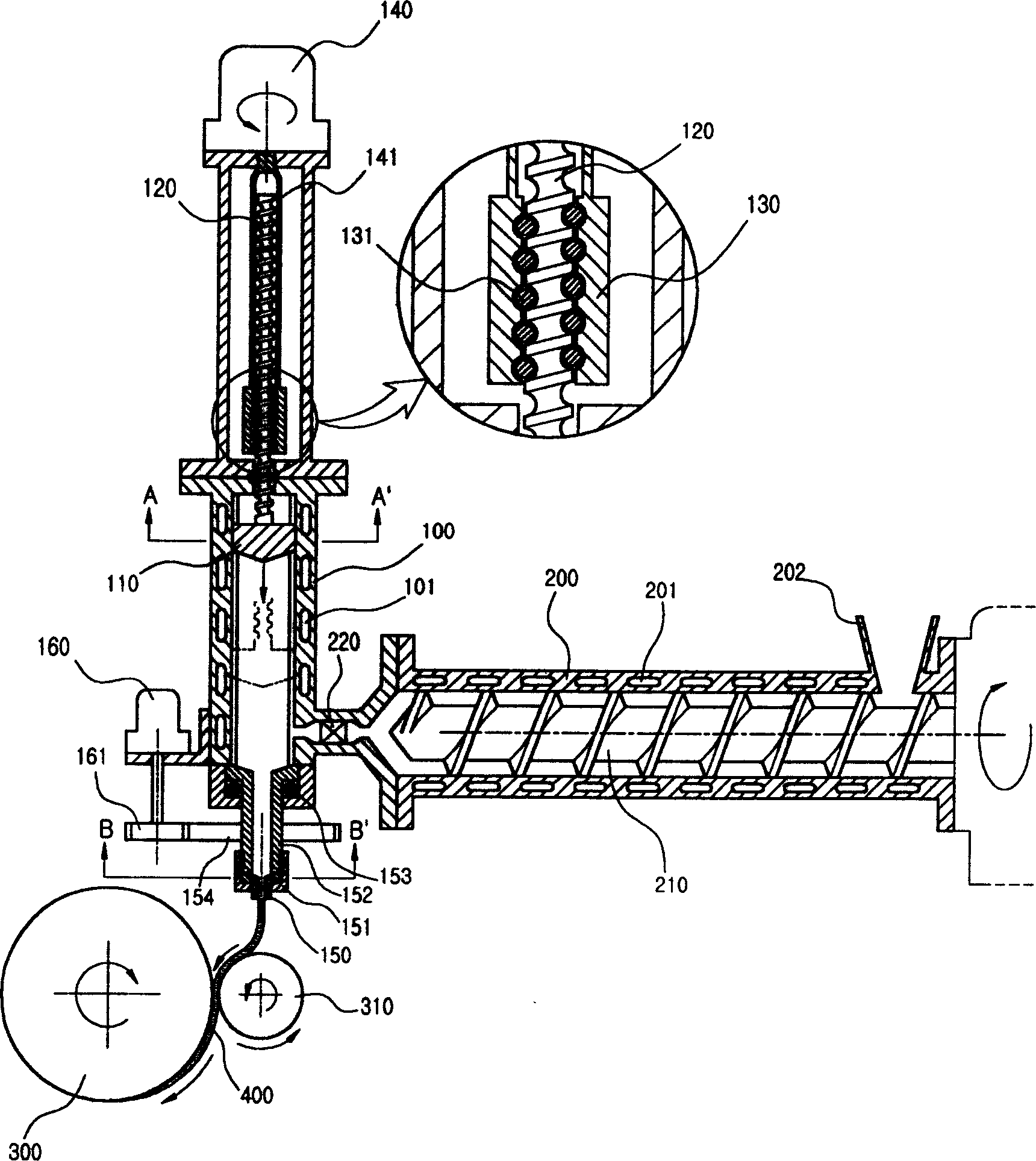

[0046] Such as figure 1 , the present invention is made of injection cylinder 200 made into a plastic state after heating the raw material, and its accessory device, and maintains the heated state and plastic state of the material and molds these into a rubber belt 210 after extrusion, and a feeding hopper 202 for supplying the raw material The shape is a general shape used when molding rubber products or synthetic resin products.

[0047] Although such an injection cylinder 200 has the advantage of continuous molding, because the rotating material of the injection screw 210 will be squeezed out, it is not only difficult to adjust accurately due to the rolling path formed in a spiral shape along the injection screw 210 and the elasticity of the material. Injection speed and injection volume, and the control response speed is also very slow.

[0048] Therefore, after the present invention accommodates a certain amount of injection material, these extruding cylinders 100 press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com