Straight pipe butt welding auxiliary device

A technology for auxiliary devices and straight pipes, applied in auxiliary devices, welding/cutting auxiliary equipment, positioning devices, etc., can solve the problems of poor control of gaps, affecting the quality of pipe networks, and uneven alignment of straight pipes, etc., to achieve a neat interface tilt , the connection is firm, the interface is neat and the clearance is appropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

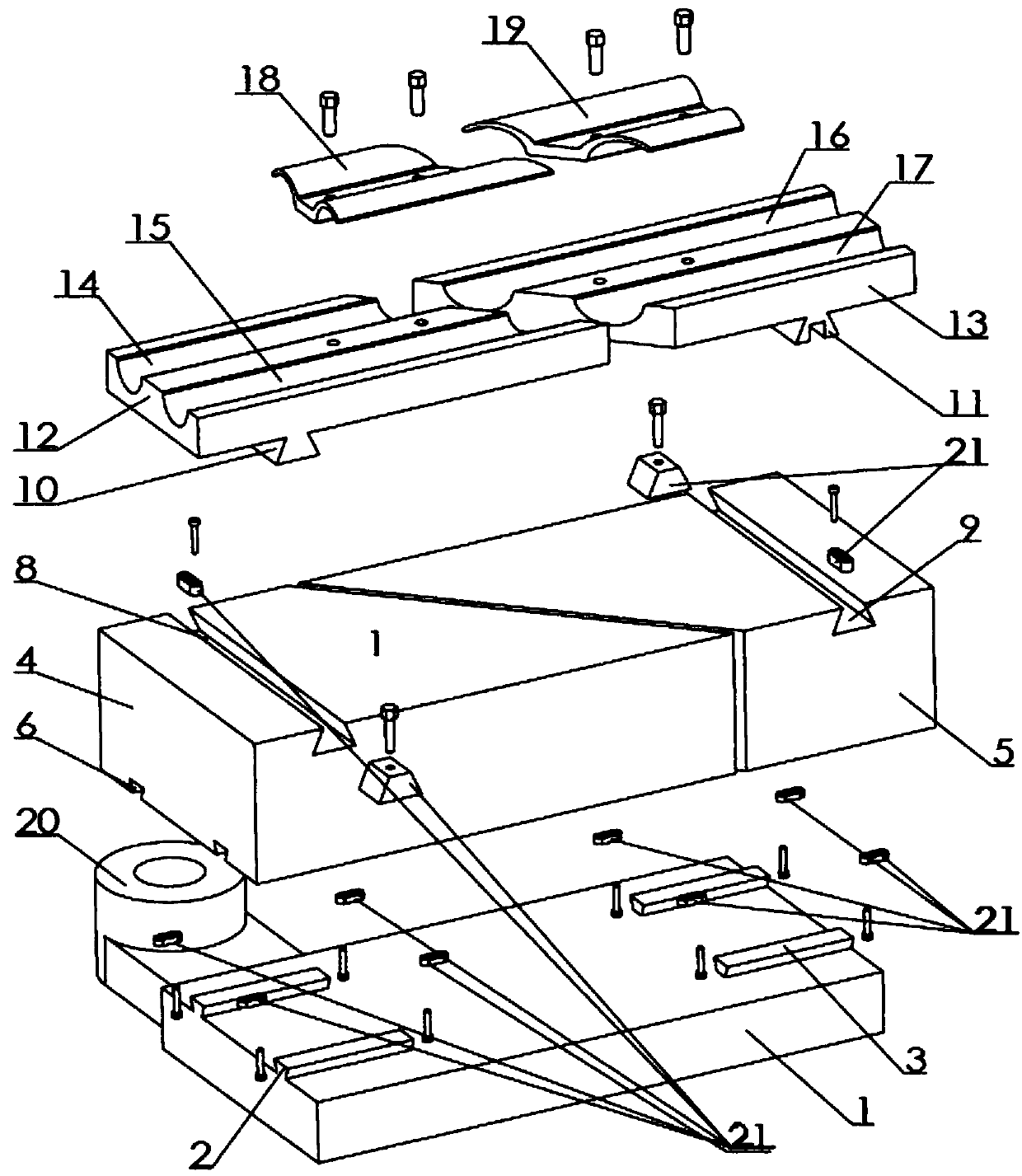

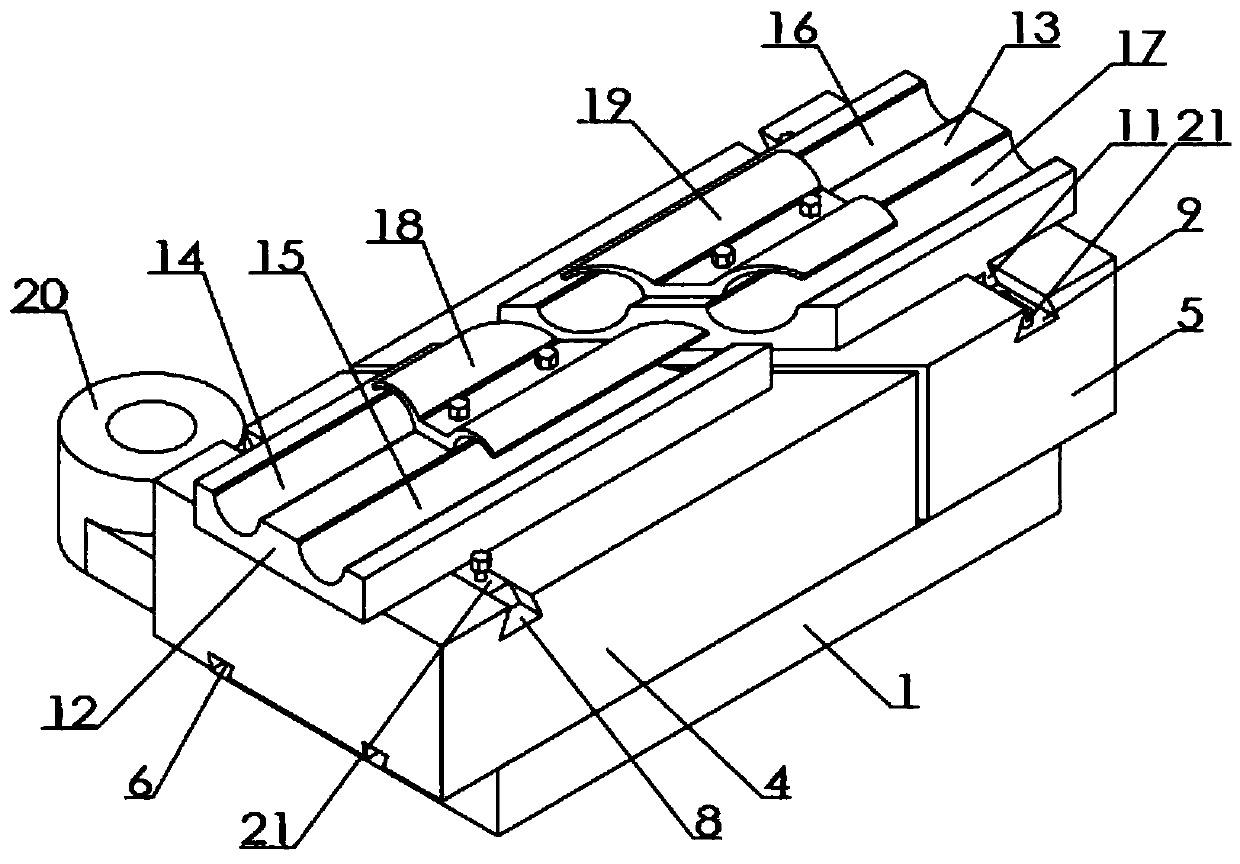

[0012] Examples of the present invention figure 1 , 2 As shown, the straight pipe butt welding auxiliary device is provided with a platform 1, and the left and right ends of the platform are respectively connected with a left guide rib 2 and a right guide rib 3 with dovetail-shaped cross-sections in the left and right directions, and a left base block 4 is arranged on the upper part of the platform. And right base block 5, left base block is provided with the left guide groove 6 that cooperates with left guide rib below the left base block, is provided with the right guide groove that cooperates with right guide rib below the right base block, left base block and right base block inboard relative Parallel to the vertical plane and the parallel plane is at an angle of forty-five degrees to the direction of the left guide rib, the left base block and the right base block are respectively provided with a left guide groove 8 and a right guide groove 9 in the front and back directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com