Print head of printer and gap spacer used for the print head

A printing device and printing head technology, applied in printing and other directions, can solve problems such as unable to maintain the gap between the yoke plate and unable to obtain printing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

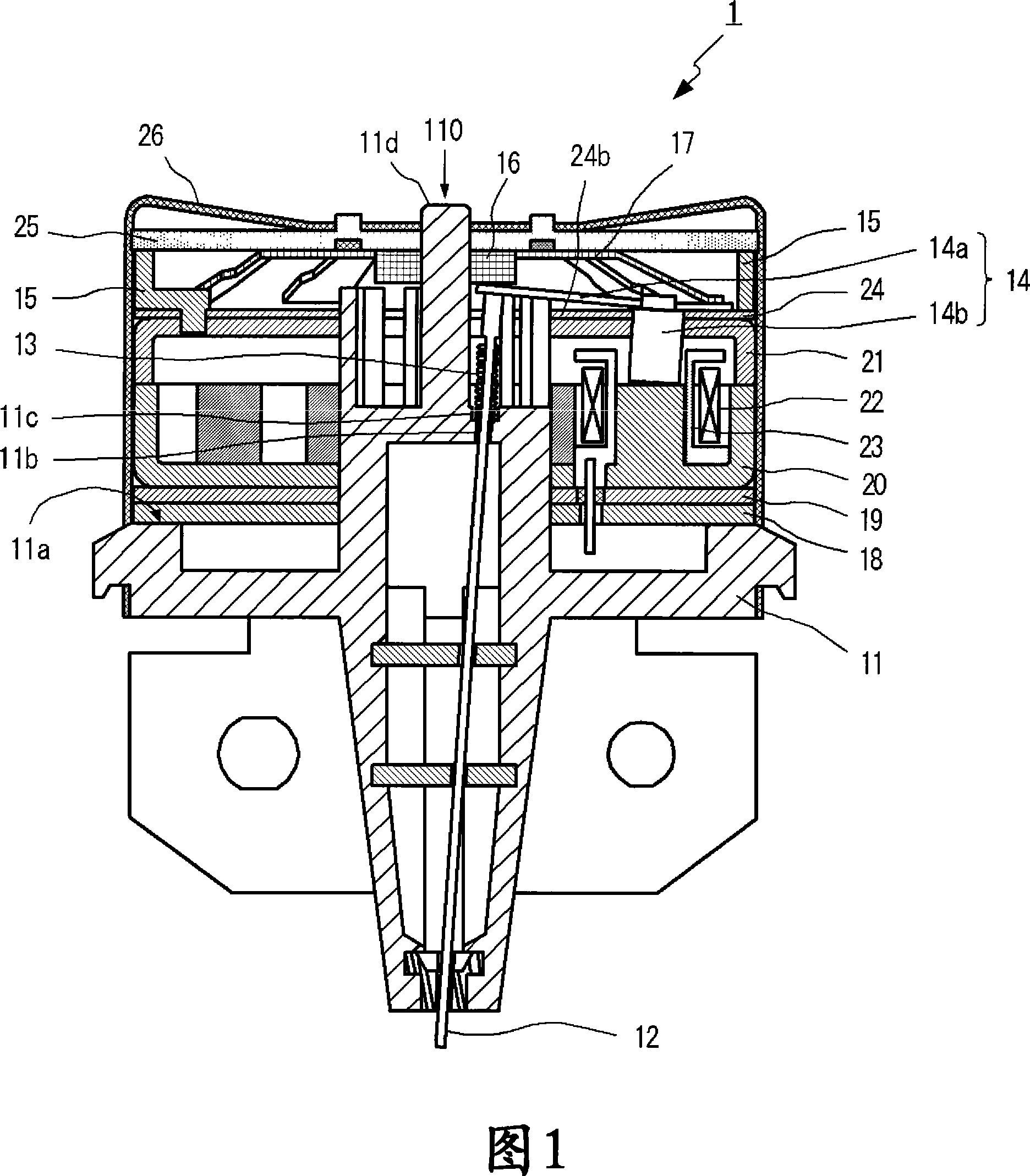

[0039] Next, a print head of a printing device according to an embodiment of the present invention will be described with reference to the drawings.

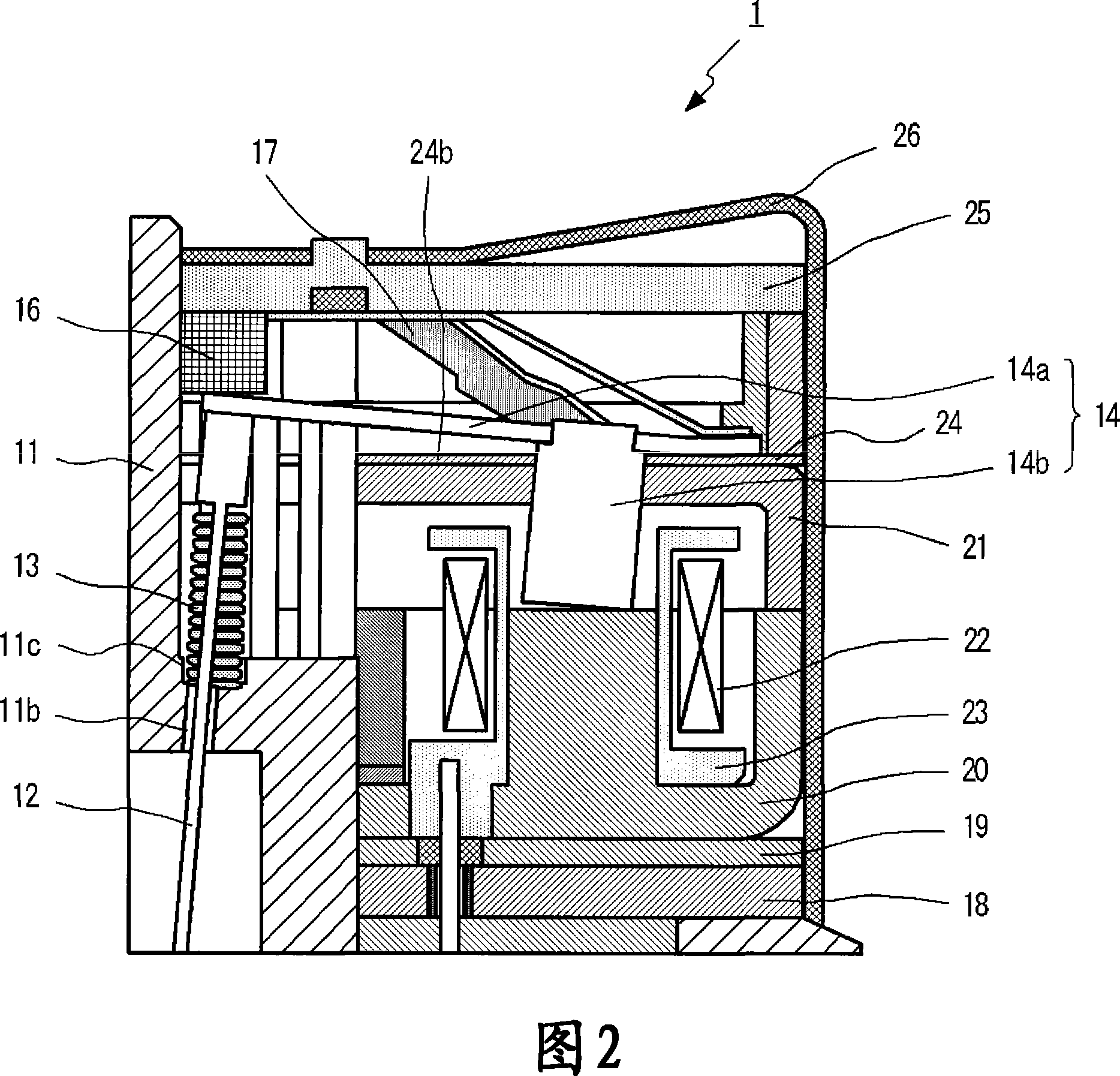

[0040] The configuration of the print head 1 of the printing apparatus according to the present embodiment is shown in FIG. 1 . In addition, a partially enlarged view of FIG. 1 is shown in FIG. 2 .

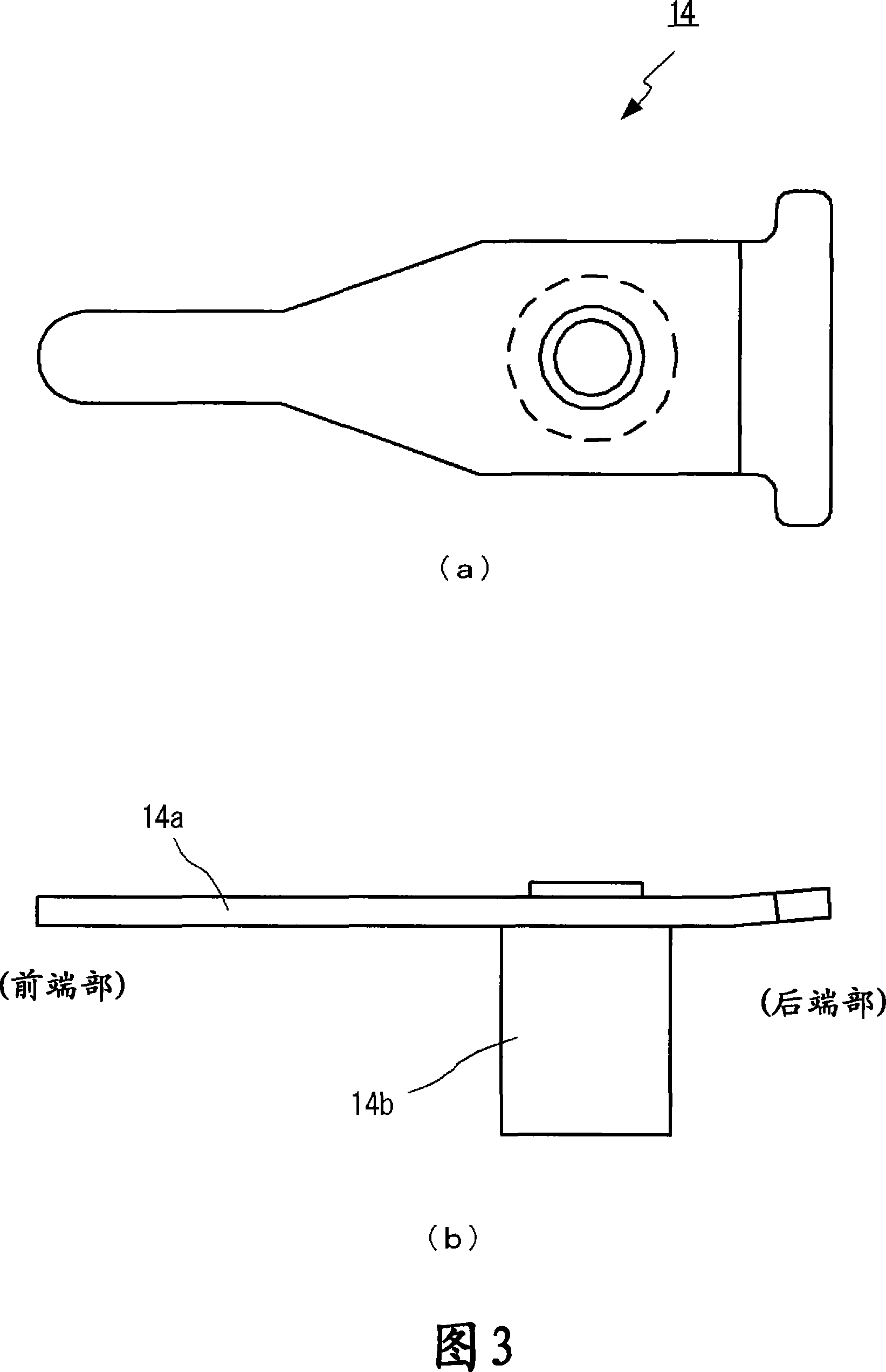

[0041] The print head 1 of the printing device according to this embodiment includes: a needle cartridge 11, a printing needle 12, a return spring 13, a printing lever mechanism part 14, a lever guide part 15, a stopper 16, a lever spring 17, and spacers 18 and 19. , Yoke shell 20, yoke plate 21, drive coil 22, coil frame 23, gap spacer 24, head cover 25, locking spring 26.

[0042] The needle box 11 is used to house components in the print head 1 such as printing needles 12, and may be formed of, for example, plastic. The cross section of the needle box 11 relative to the central axis 110 is circular. FIG. 1 shows a cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com