Patents

Literature

38 results about "Valve float" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

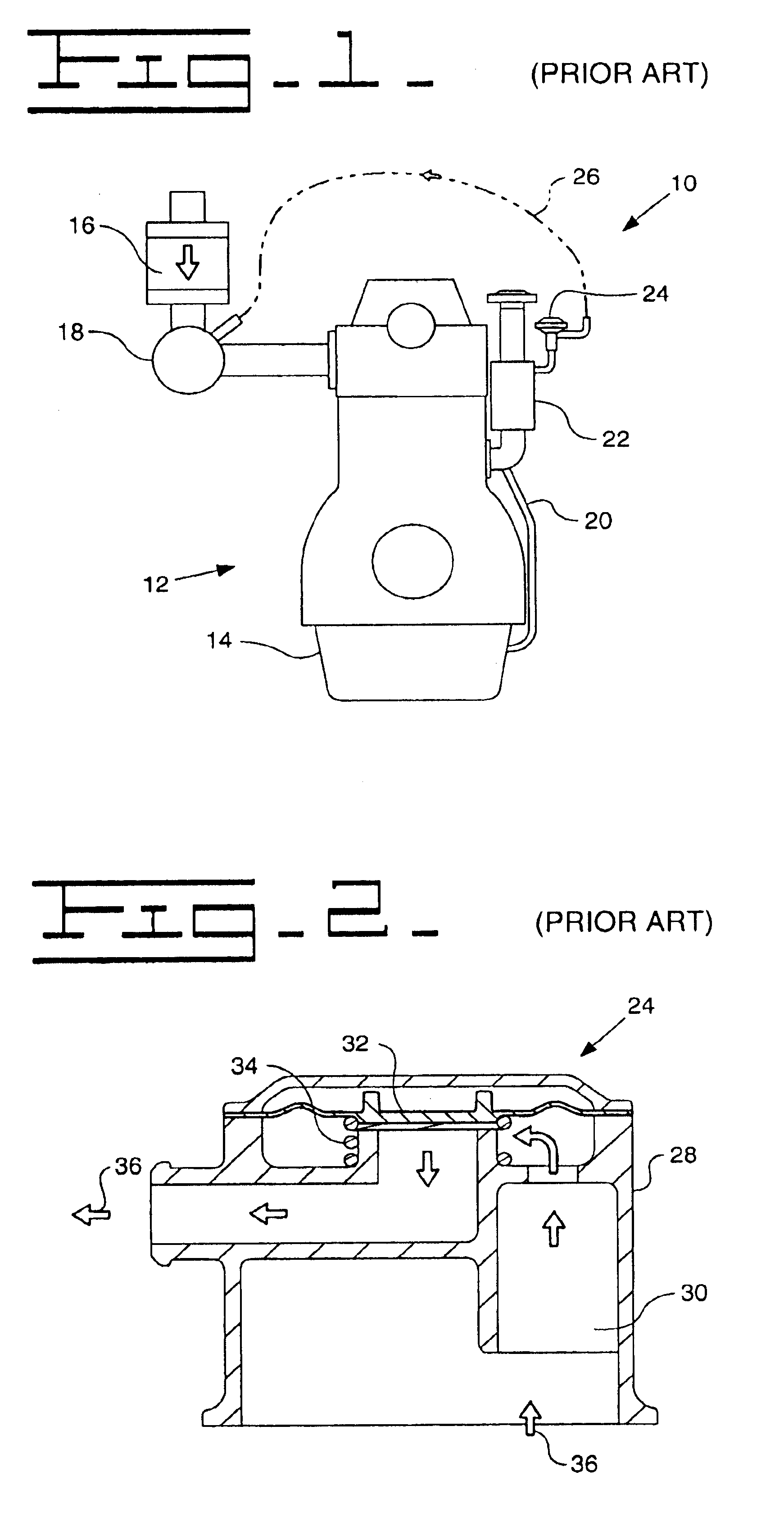

Valve float is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valvetrain do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance and potentially increases engine emissions. There is also a significant risk of severe engine damage due to valve spring damage and/or pistons contacting the valves.

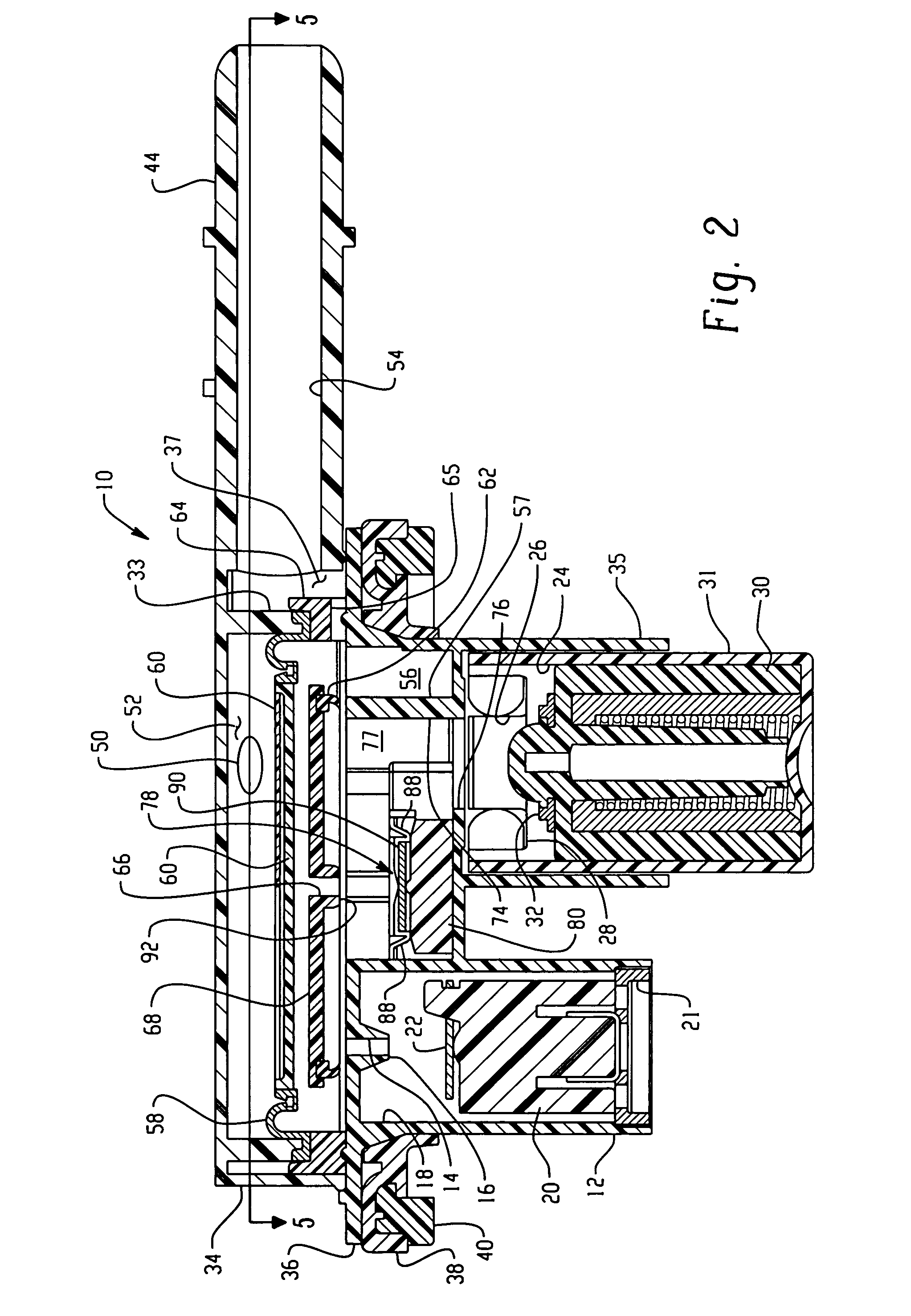

Overhead rotary valve for engines

InactiveUS6308677B1Simple sealing deviceImprove sealingMachines/enginesRotary slide valveCombustion chamberExhaust valve

An overhead rotary valve fitted into a cylinder head with diametrical polygonal openings formed therein for use in combination with an internal combustion engine, driven to bring intake and exhaust ports into and out of alignment with passages leading to and from the combustion chamber. Sleeve bearings are fitted in the cylinder head that provide surface sealing, and annular sealing members prevent the air / fuel mixture or exhaust gases from flowing into regions intermediate ports and individual cylinders. Utilizing this overhead rotary valve and associated seals and bearings increases the efficiency and performance of an internal combustion engine. The overhead rotary valve rotating, at one quarter the speed of the crankshaft, minimizes wear and noise levels, self cleans the ports, allows the engine to operate at higher rpm and imparts proper opening and closing of passages at the proper sequence of valve timing without concern of valve float. The instant invention removes the need for reciprocating intake and exhaust valves, camshafts, rocker arms, lifters, push rods, valve guides and retainers, and other related hardware for actuation, significantly increasing the reliability and effectiveness of the internal combustion engine, while reducing overall manufacturing costs.

Owner:BOHACH WILLIAM LOUIS +1

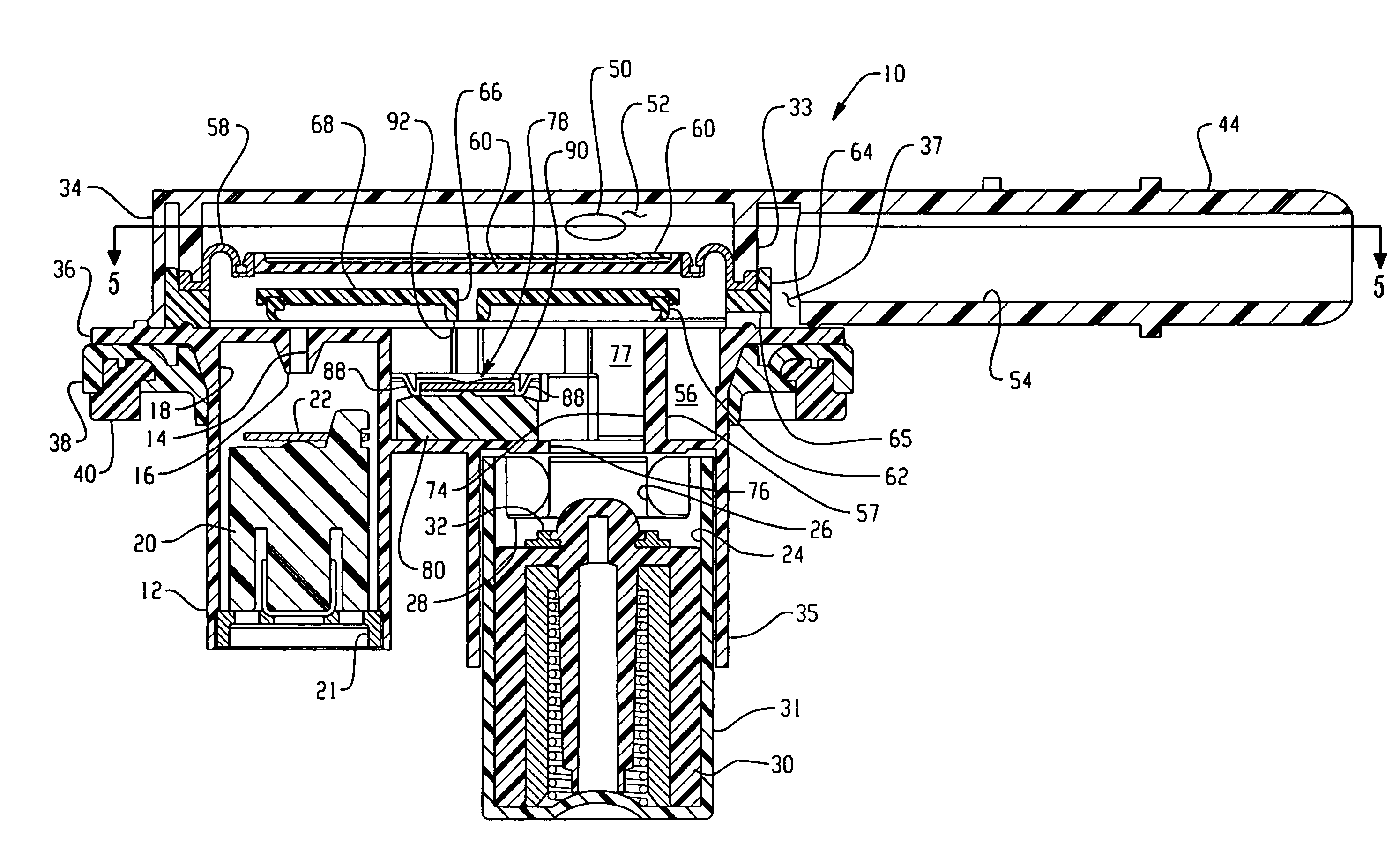

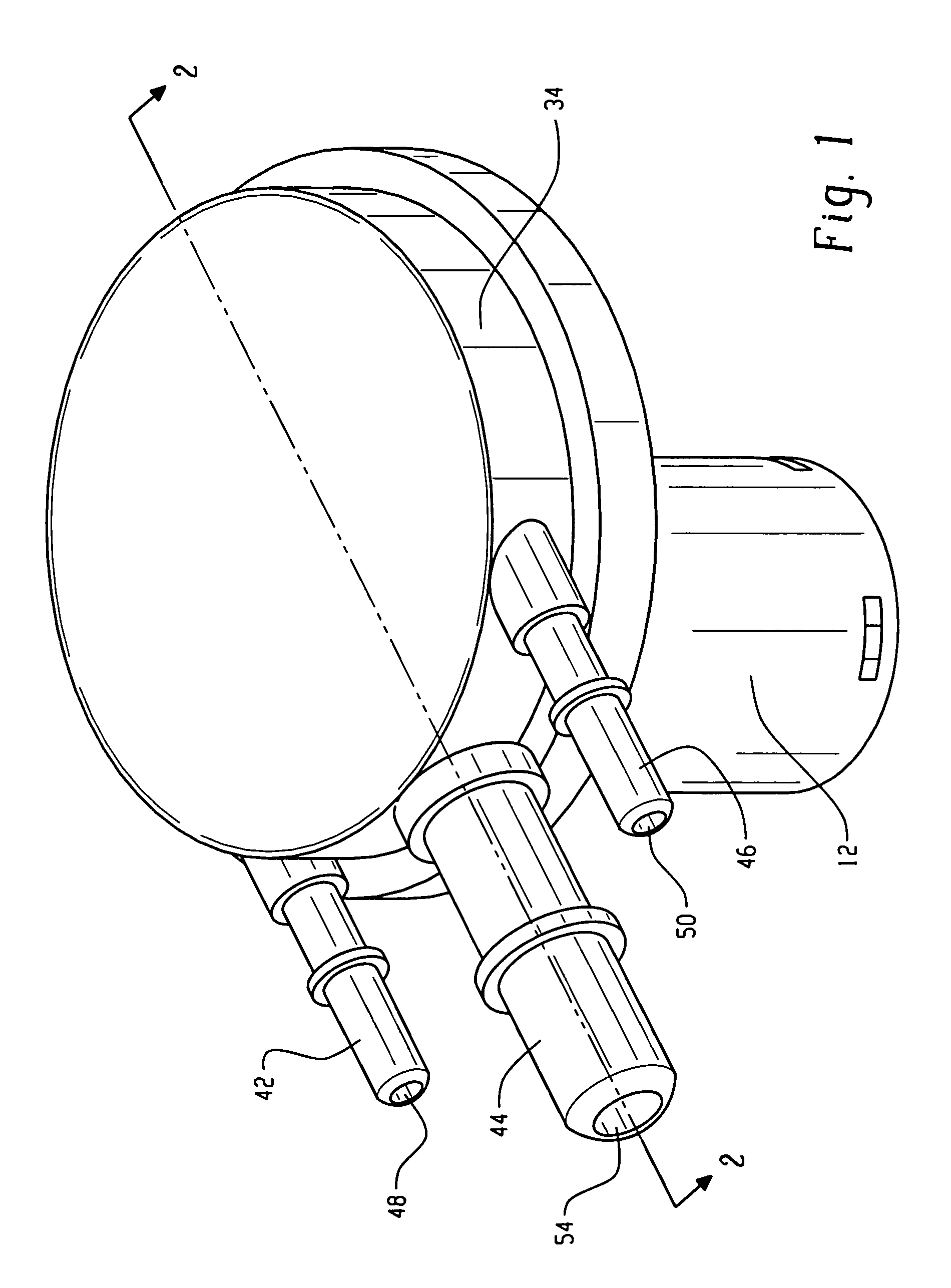

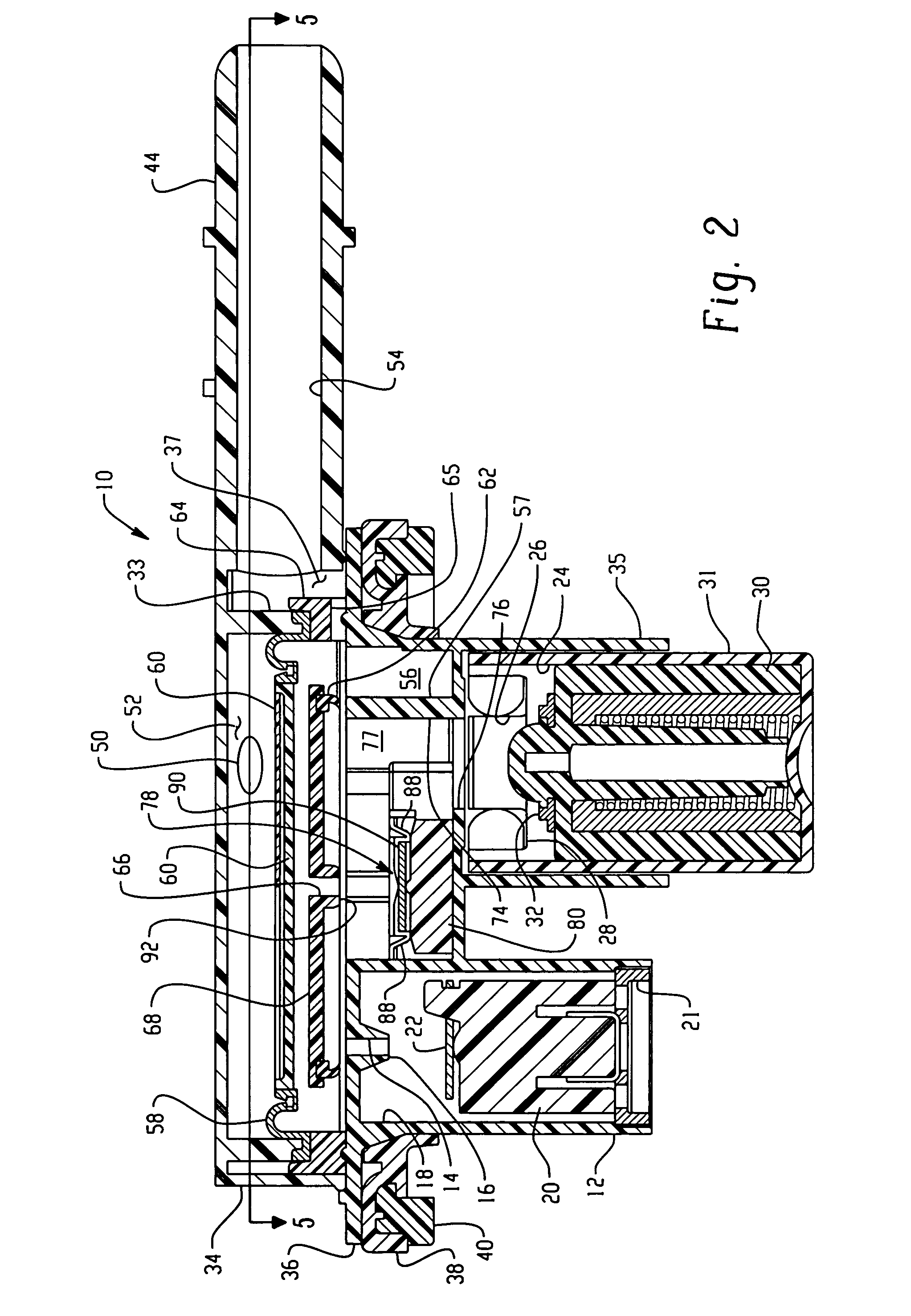

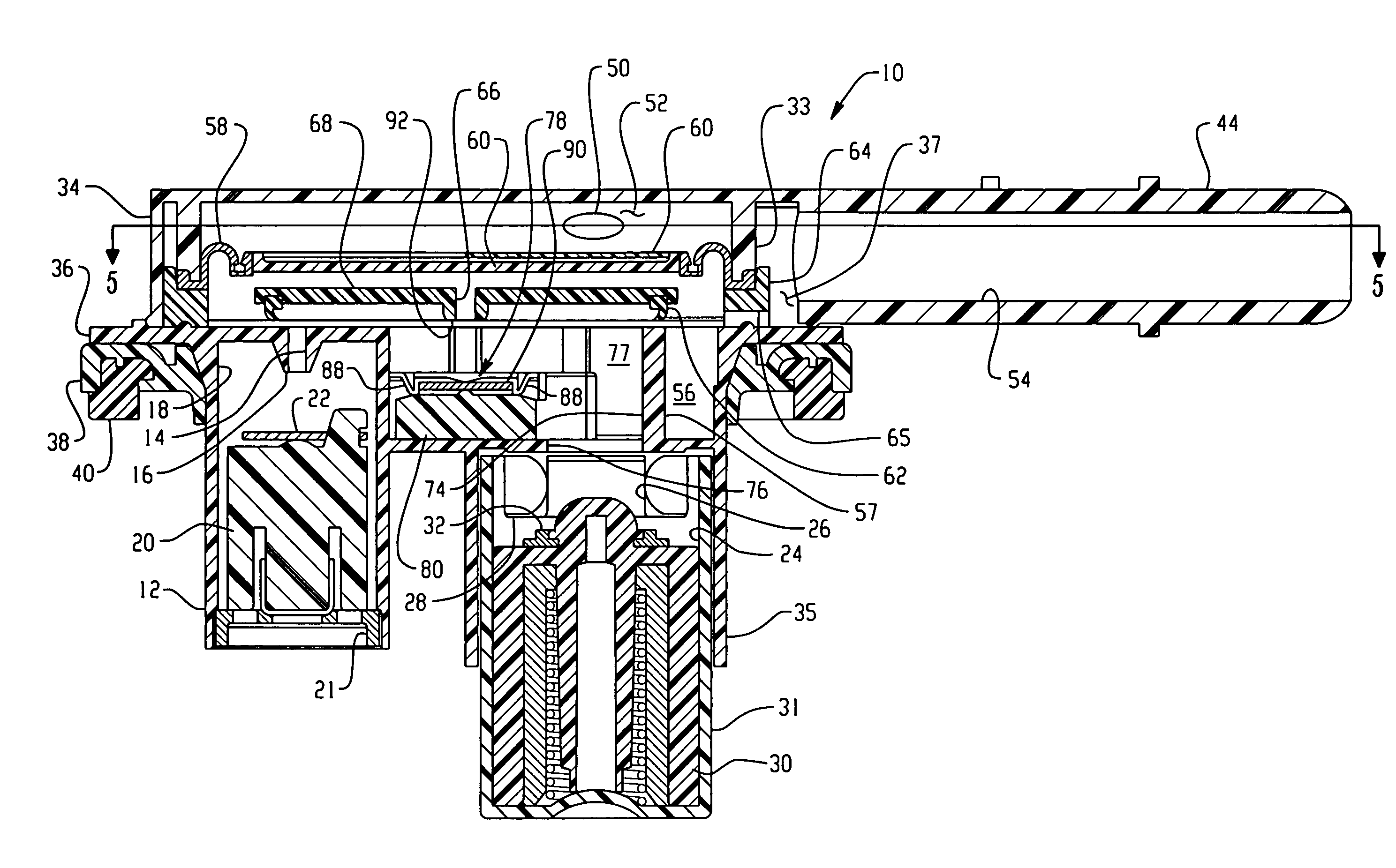

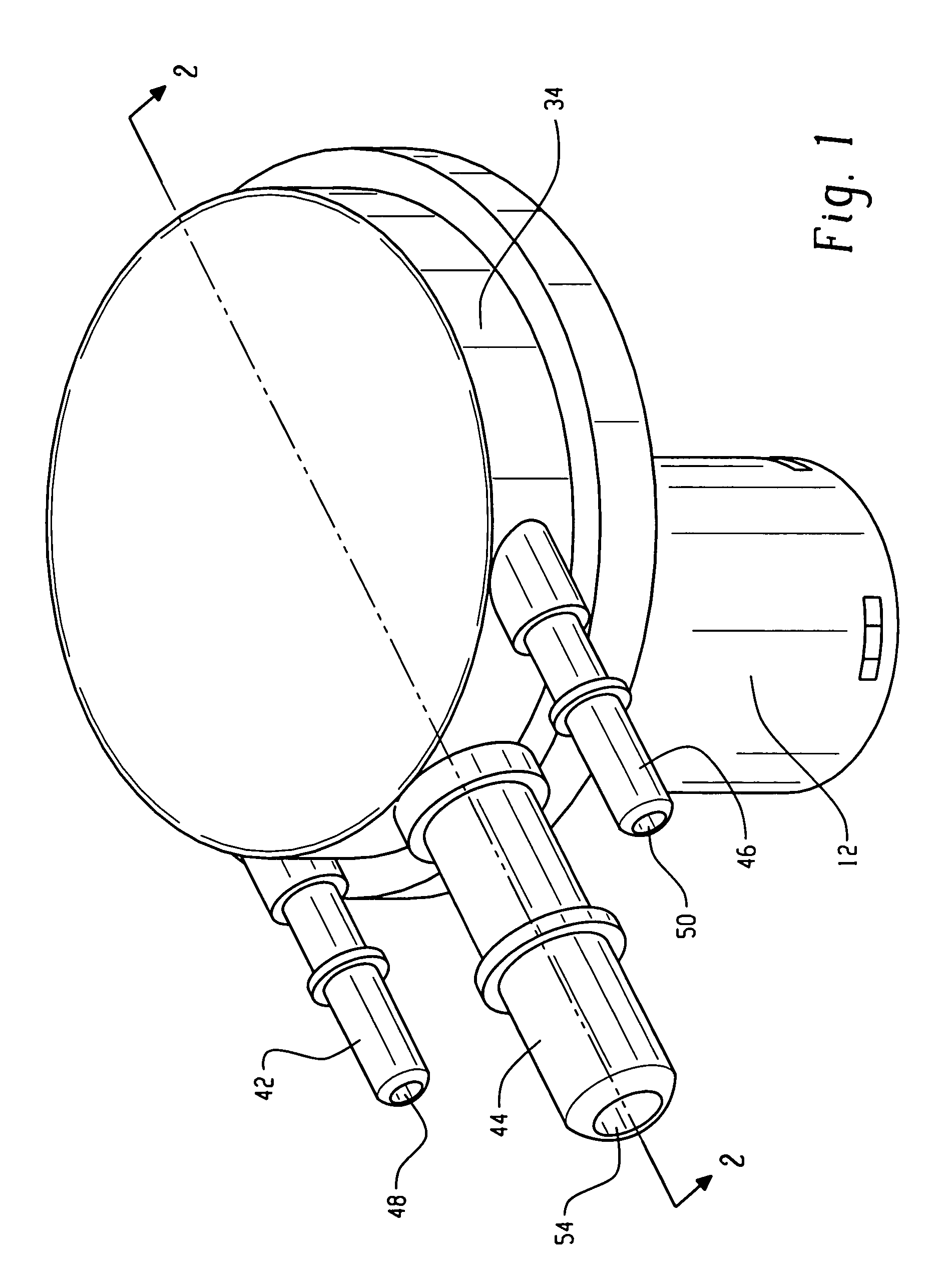

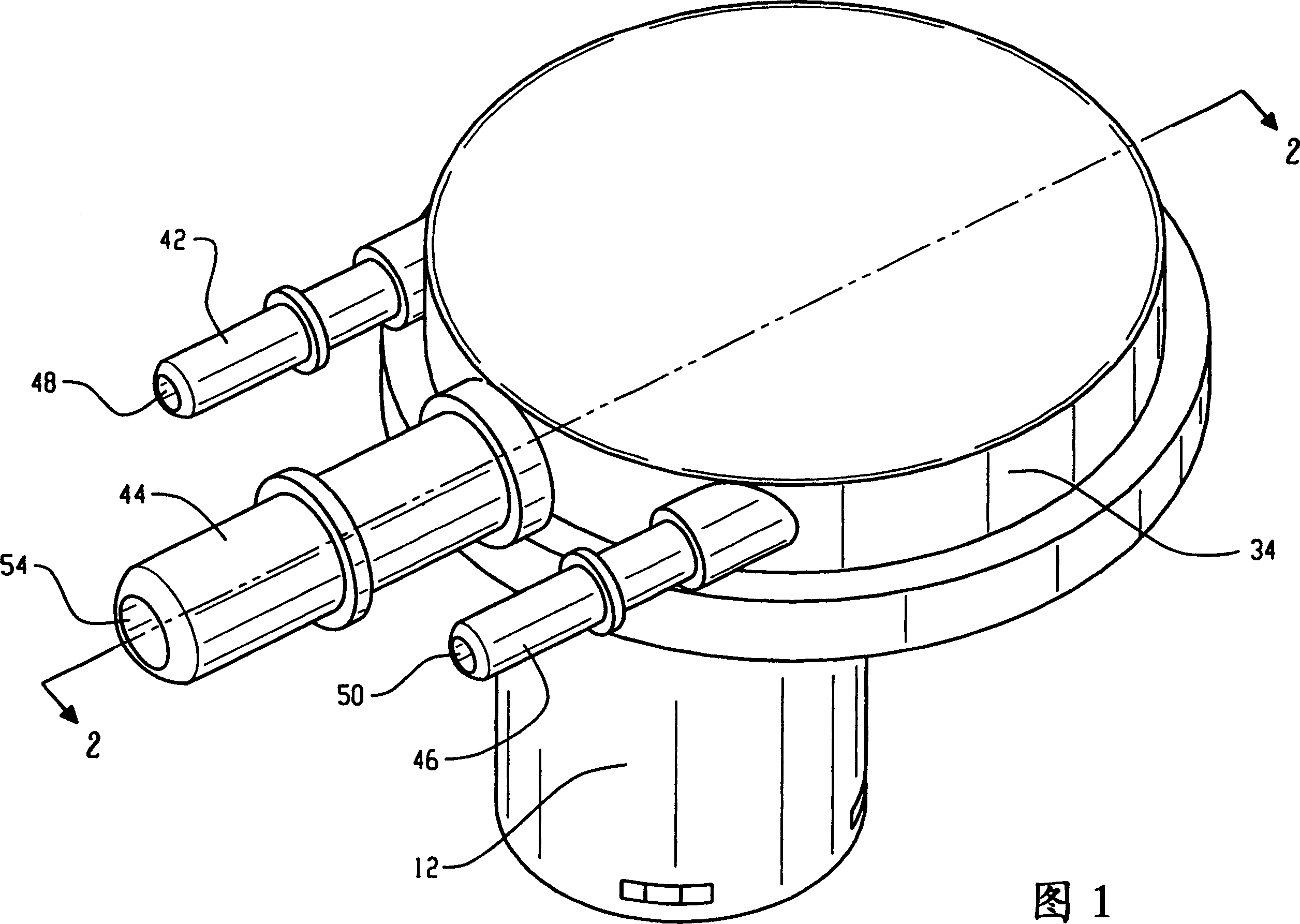

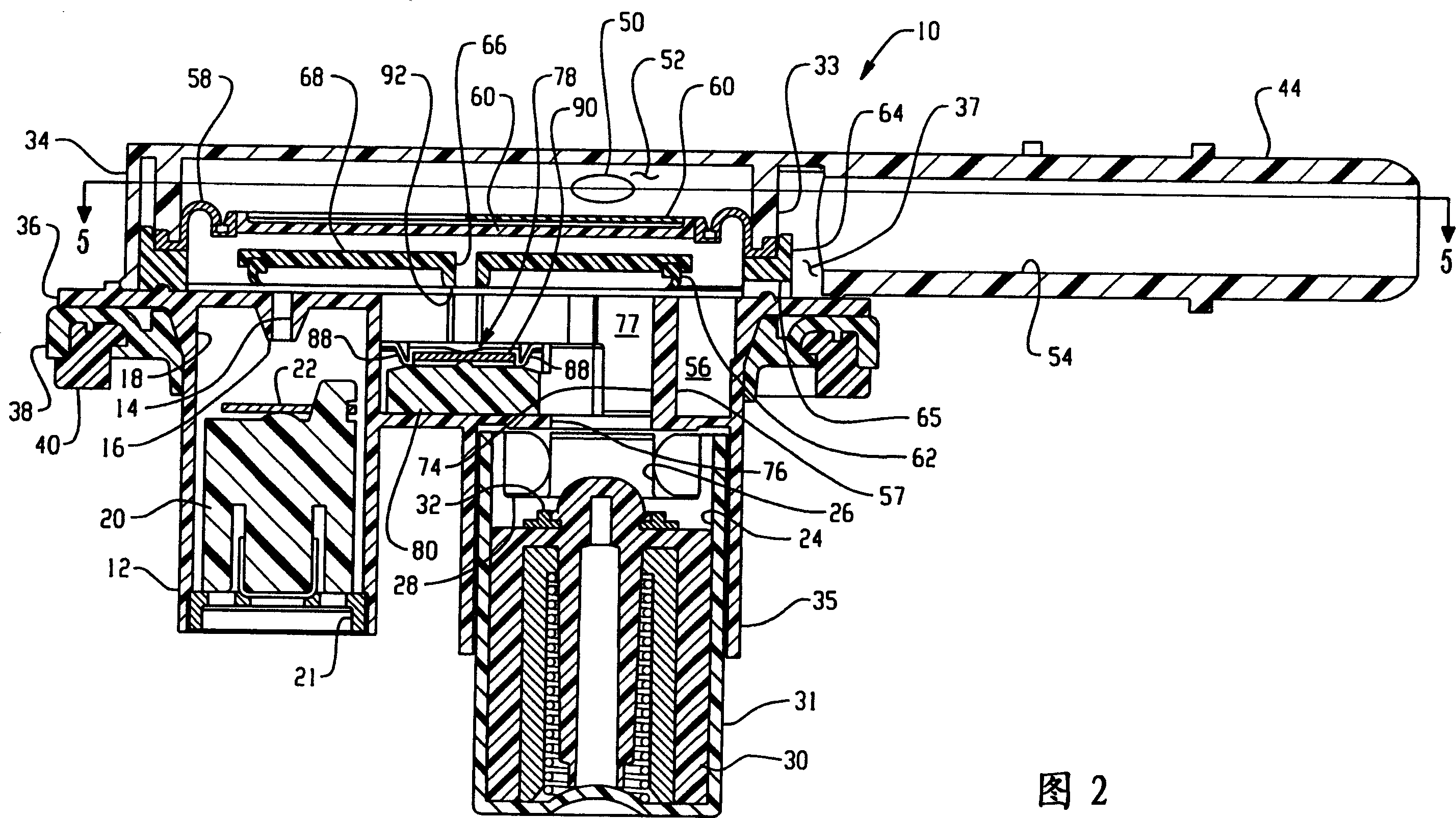

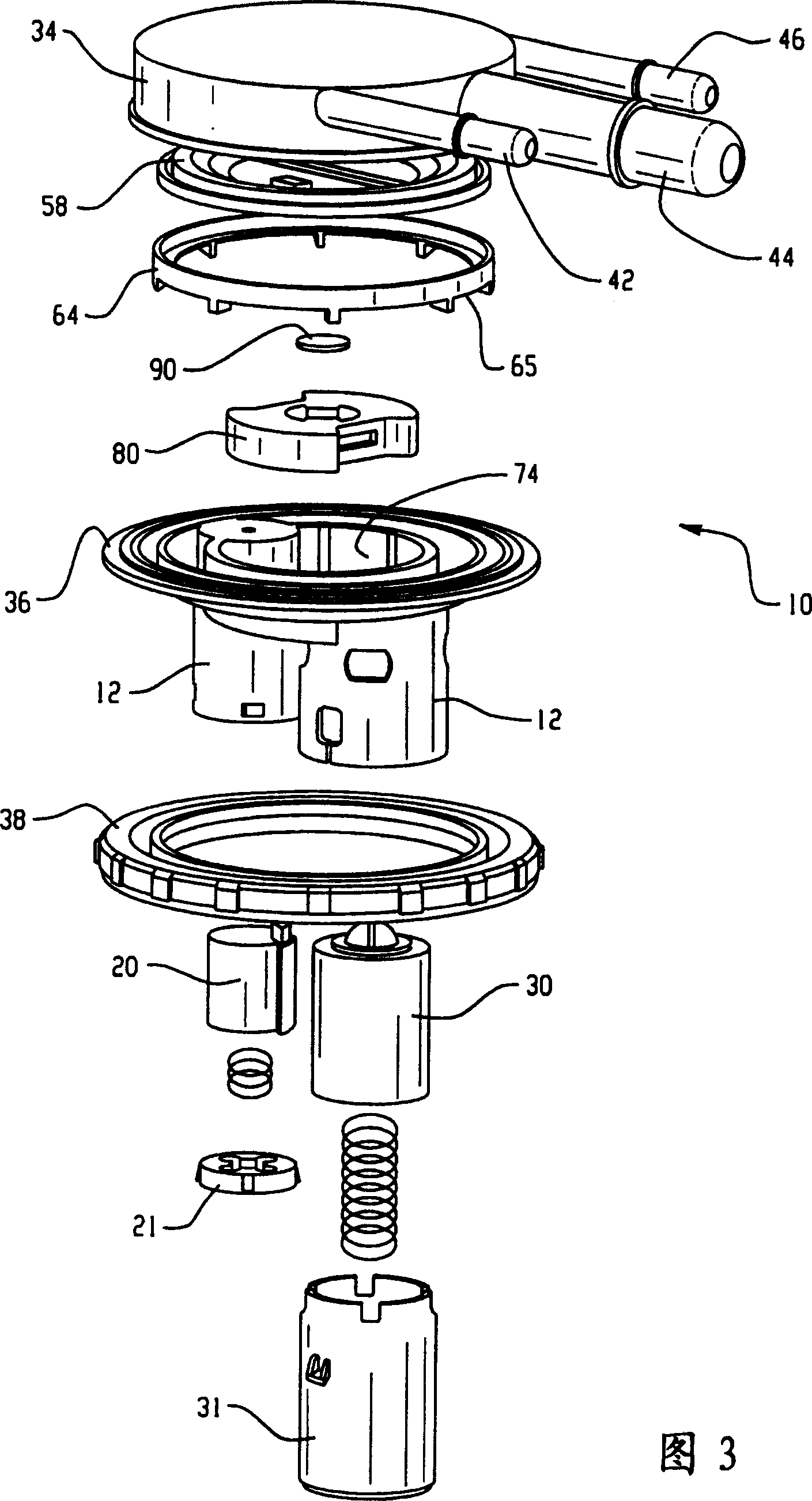

Fuel vapor vent valve float assembly and method of making same

ActiveUS7163023B2Easy to assemblePrevent escapeOperating means/releasing devices for valvesPipe elementsExhaust valveValve float

A float assembly for a multifunction fuel vapor vent valve with a float having a recess formed in the upper surface of the float with a slot formed in the side of the float and communicating with the recess. A raised surface portion is formed in the bottom of the recess and downwardly extending projections are formed in the slot at the recess. A flexible wafer like valve disk is inserted in the slot and deformed or curled to pass under the projections and over the raised surface and into the recess. When fully received in the recess the disk returns to its flat configuration; and, the downward projections prevent removal without distortion. Radially inwardly projections about the recess retain the disk for limited lost motion in the direction of float movement.

Owner:EATON INTELLIGENT POWER LTD

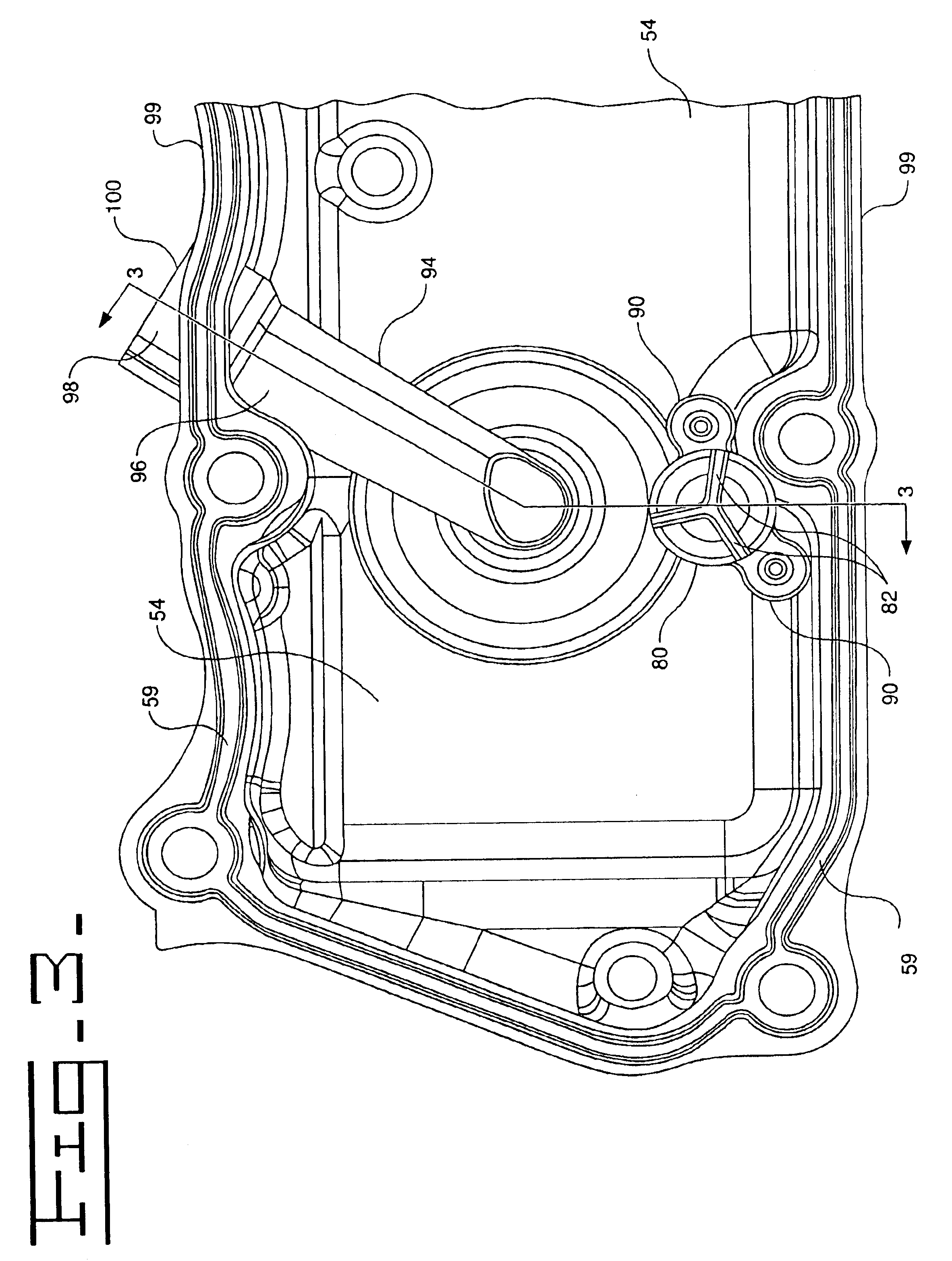

Combined shut-off valve and cover for an engine breather system

In prior art engine breather systems, shut off valves that prevent oil from entering the engine induction system have been mounted externally on the engine and require associated external pipework. Both the shut off valve and pipework are prone to damage and leaking. The closed circuit breather apparatus of the present invention includes a cylinder head cover and a shut off valve provided beneath the cylinder head cover. The shut off valve includes an aperture in communication with a blow-by gas inlet passage and a valve float restrained to move between a first position in which the aperture is open and a second position in which the aperture is closed. Preferably the shut off valve is integral with the cylinder head cover. The shut off valve is thus packaged inside the engine valve chamber, making it easy to fit and eliminating leak paths.

Owner:PERKINS ENGINES

Fuel vapor vent valve float assembly and method of making same

ActiveUS20060011234A1Easy to assemblePrevent escapeOperating means/releasing devices for valvesVenting valvesValve floatEngineering

A float assembly for a multifunction fuel vapor vent valve with a float having a recess formed in the upper surface of the float with a slot formed in the side of the float and communicating with the recess. A raised surface portion is formed in the bottom of the recess and downwardly extending projections are formed in the slot at the recess. A flexible wafer like valve disk is inserted in the slot and deformed or curled to pass under the projections and over the raised surface and into the recess. When fully received in the recess the disk returns to its flat configuration; and, the downward projections prevent removal without distortion. Radially inwardly projections about the recess retain the disk for limited lost motion in the direction of float movement.

Owner:EATON INTELLIGENT POWER LTD

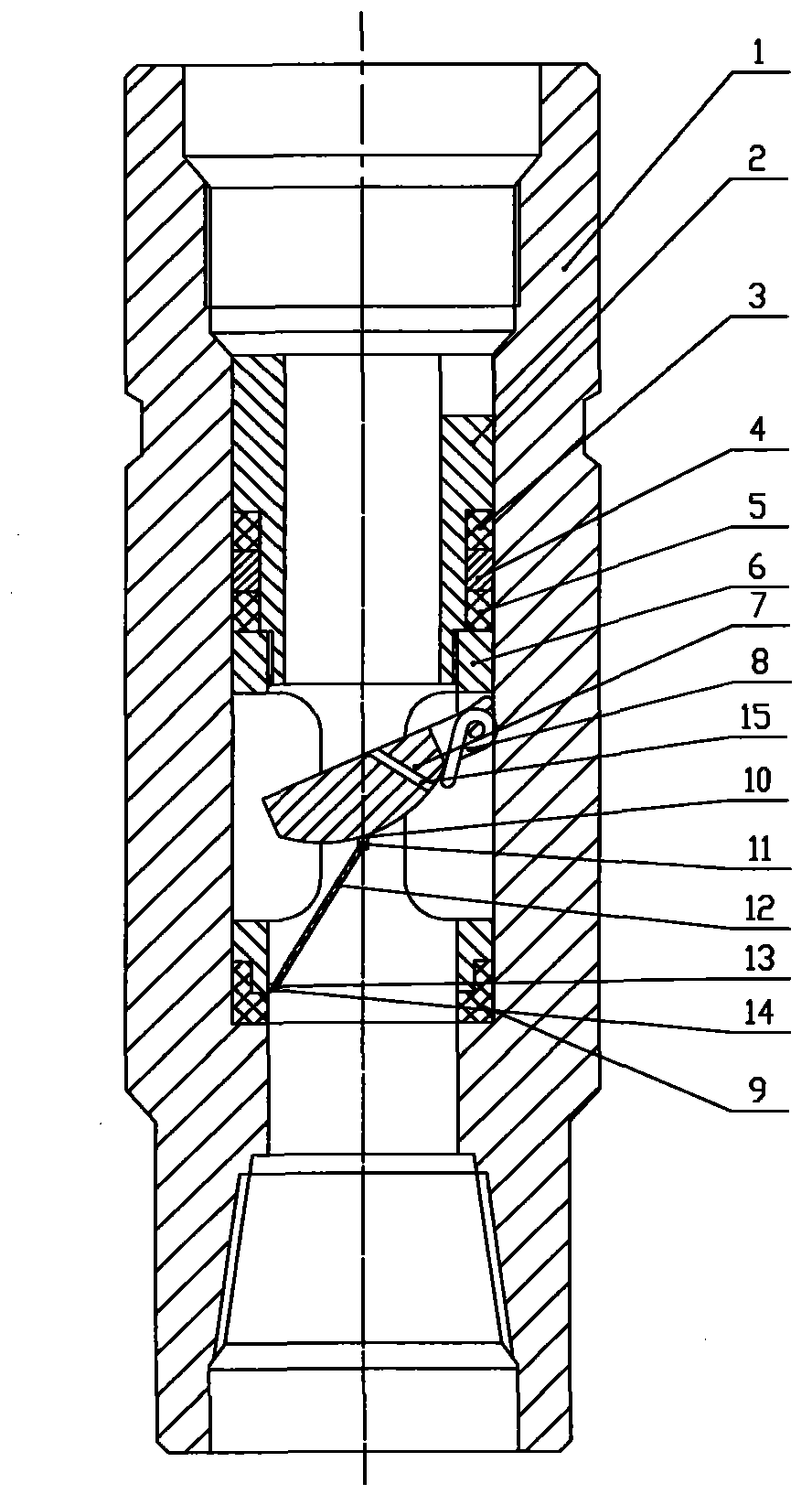

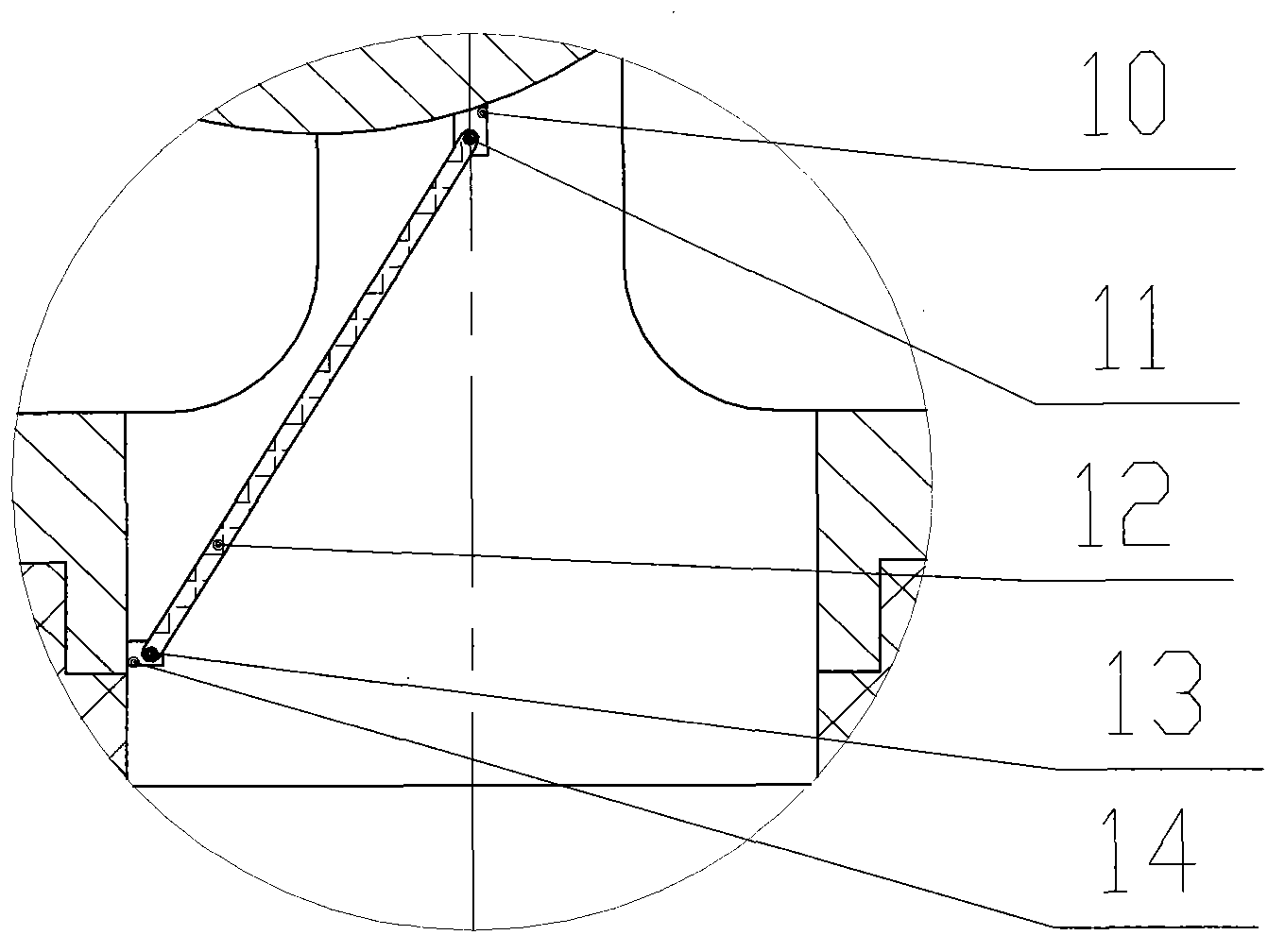

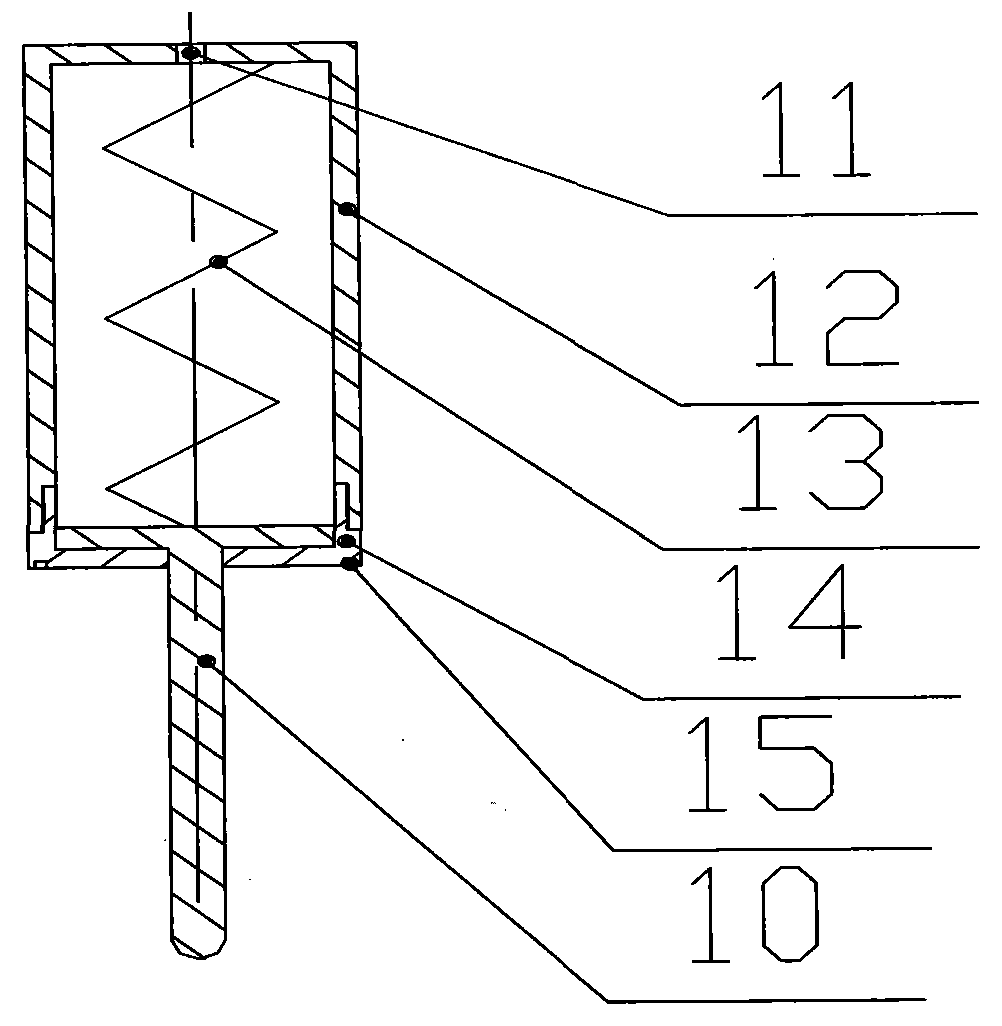

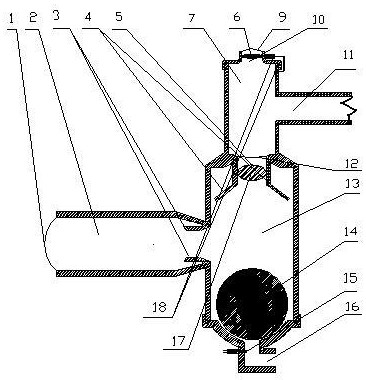

Oil spillage cutoff valve

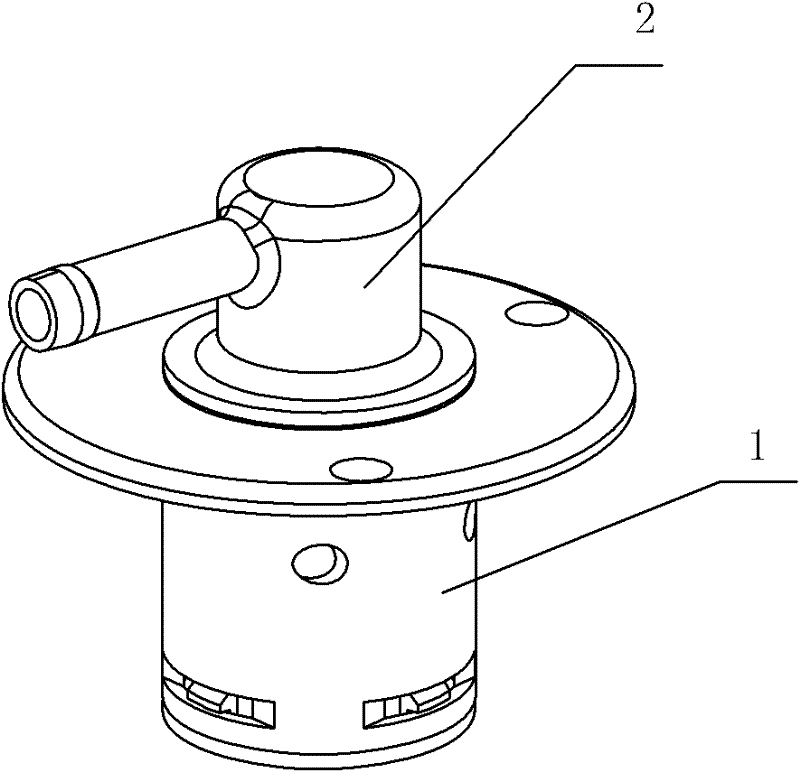

InactiveCN102229320APrevent outflowNormal air pressureOperating means/releasing devices for valvesFuel supplyFuel tankValve float

The invention discloses an oil spillage cutoff valve, which comprises a valve body and a total valve cover, wherein the valve body comprises an upper end cover and a valve bottom cover; a sealing element with a first vent is arranged in the middle of the upper end cover; a pressure holding valve is arranged in the total valve cover above the upper end cover; a valve floating core capable of floating up and down is arranged in the valve body; a first spring is arranged between the valve bottom cover and the valve floating core; the middle of the valve floating core is provided with a second vent; a pressure relief valve core is arranged below the second vent, and the pressure relief valve core is arranged in the valve floating core; a second spring is arranged between the pressure relief valve core and the valve floating core; in a stretching state of the second spring, the pressure relief valve core closes the second vent; and when the second spring is compressed, the second vent is conducted through the pressure relief valve core. The oil spillage cutoff valve has the advantages that: when an oil tank is inclined or full of oil, if the pressure in the oil tank exceeds a certain value, the high air pressure bursts through the pressure relief valve core, the second spring is compressed, the second vent in the middle of the valve floating core is conducted, and the gas in the oil tank is exhausted from the second vent, so that normal air pressure in the oil tank is ensured.

Owner:孙达立

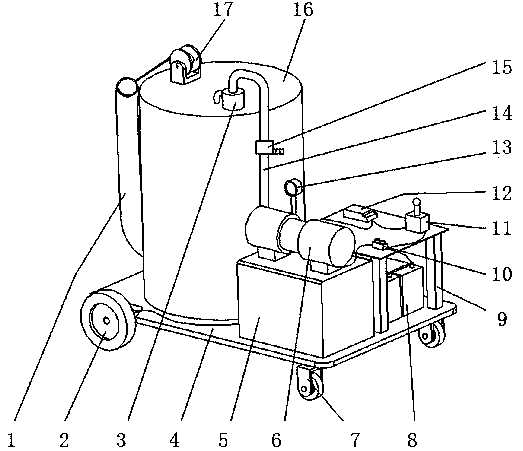

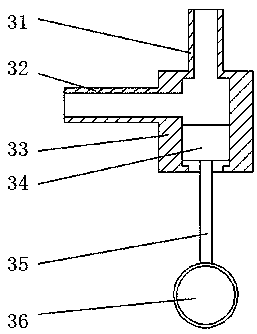

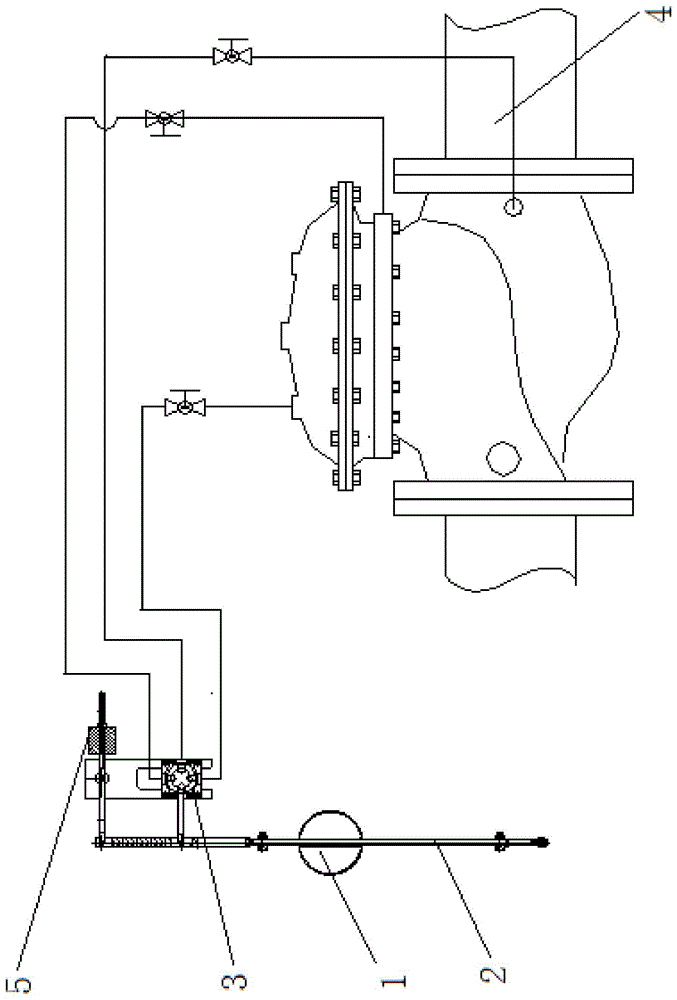

Full-automatic small-sized sewage cleaning cart

The invention relates to a full-automatic small-sized sewage cleaning cart. The whole cart comprises a sewage collection system, a transmission system and a cart body. The cart body comprises a chassis and an electrical appliance support; the sewage collection system and an electrical appliance system are arranged on the chassis of the cart body and support the whole cart to complete all operation. The sewage collection system mainly comprises a vacuum pump, a vacuum tank, a pressure gauge, a vacuum pipe, an electronic-control vacuum pipe switch, a floating ball type automatic stop valve, anda sewage collection barrel. The transmission system comprises driving wheels, universal wheels, a circuit system, a controller, a control handle, and a storage battery. The floating ball type automatic stop valve is composed of a floating ball type automatic stop valve first connector, a floating ball type automatic stop valve second connector, a floating ball type automatic stop valve body, a floating ball type automatic stop valve core, a floating ball connection rod and a floating ball. The full-automatic small-sized sewage cleaning cart is high in automatic degree and can achieve automaticoperation and save time and labor.

Owner:潍坊市科龙新汽车科技有限责任公司

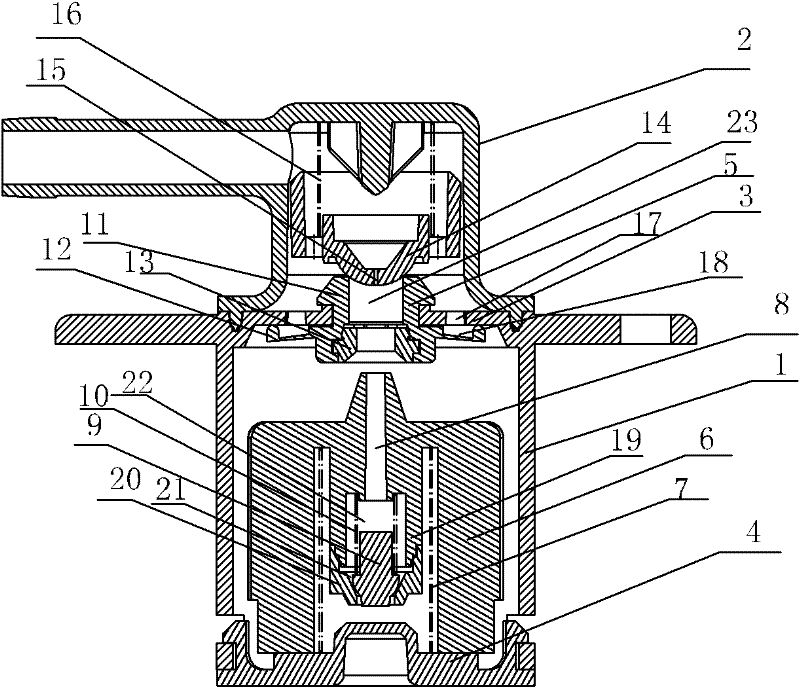

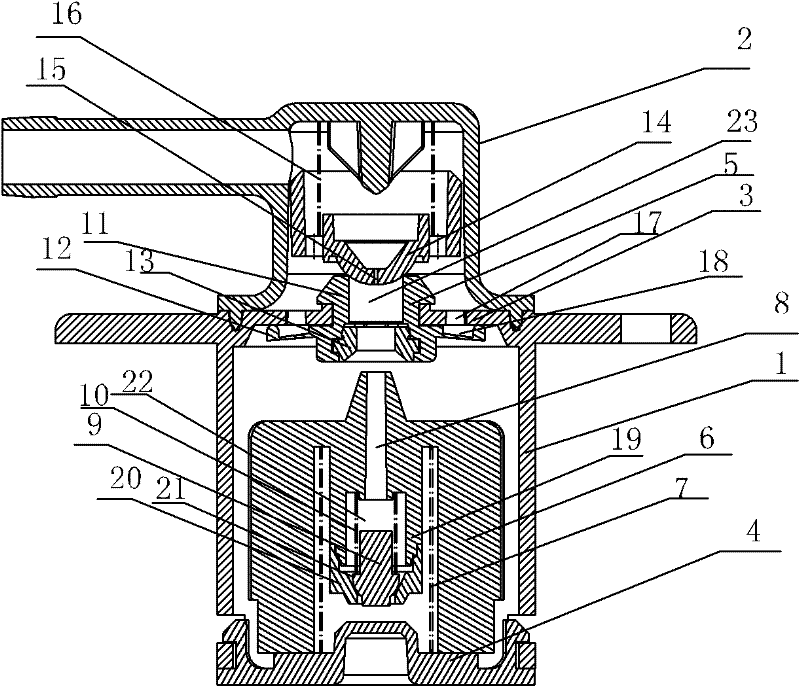

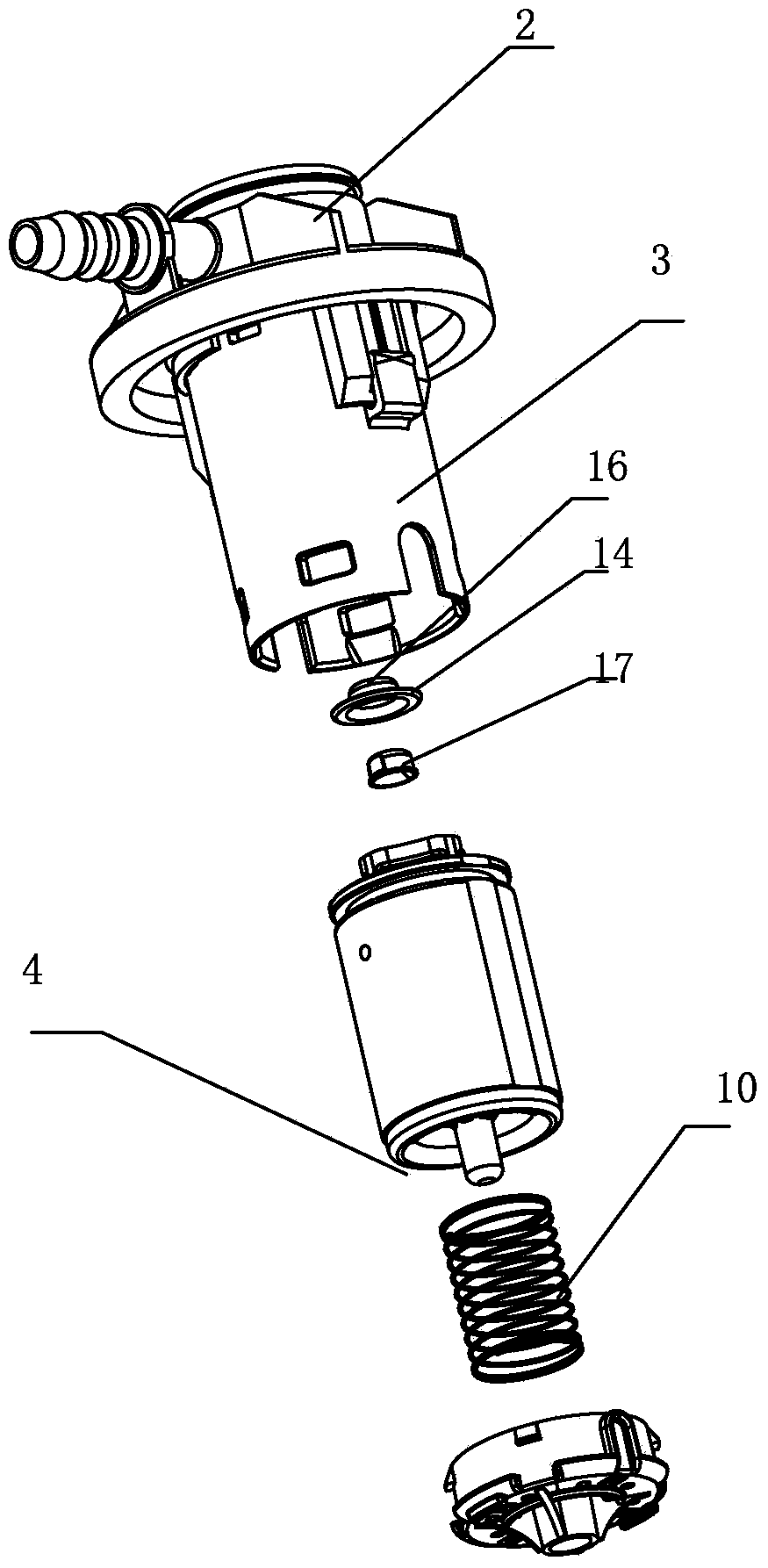

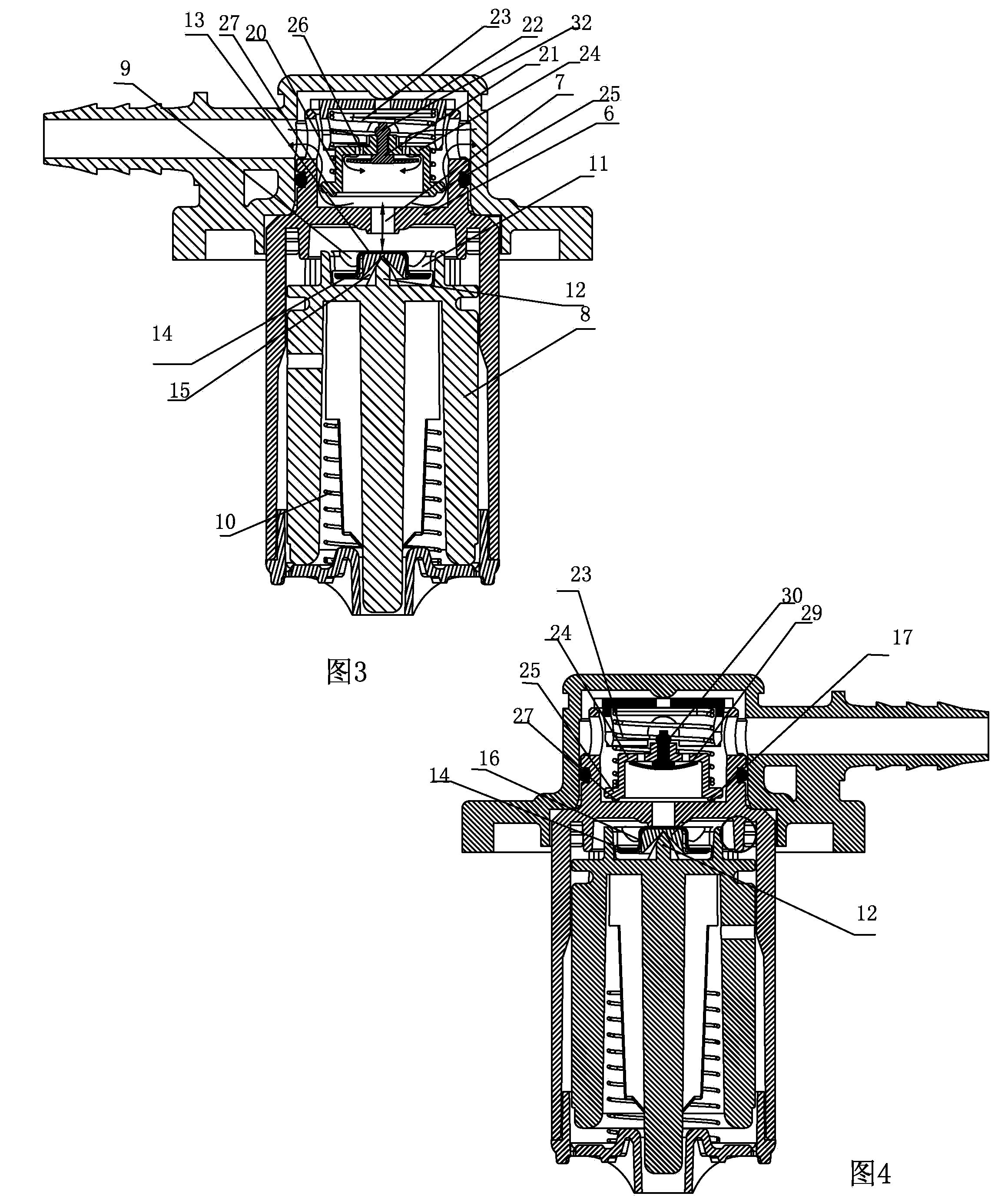

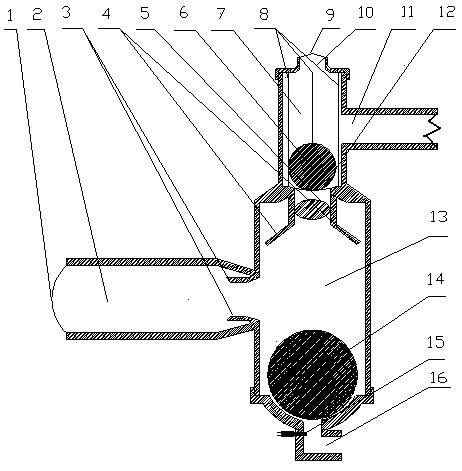

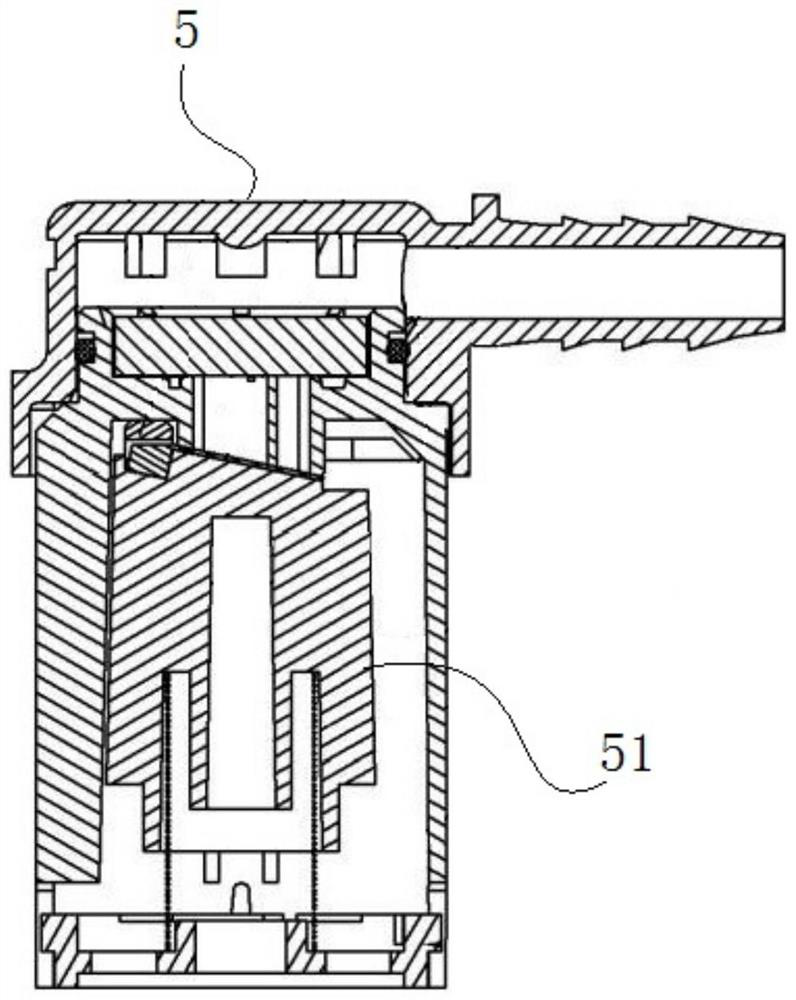

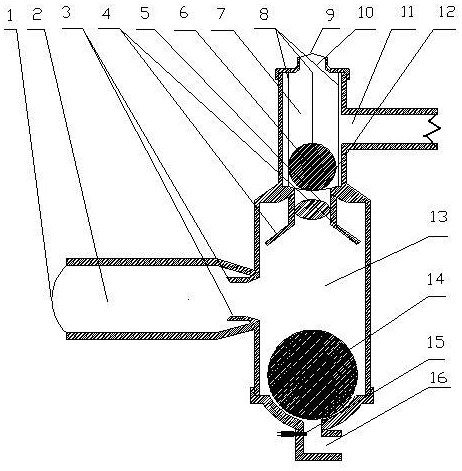

Oil filling limiting stop valve

InactiveCN105042143AEasy to installPrevent overflowEqualizing valvesSafety valvesFuel tankValve float

The invention discloses an oil filling limiting stop valve which comprises a valve body and an oil-gas separator. The valve body comprises a valve shield, a valve inner shell and a valve float element. The valve shield is arranged outside the valve inner shell. The valve float element is located in the valve inner shell. A spring is arranged between the bottom of the valve inner shell and the valve float element. The valve inner shell is connected with the oil-gas separator. A partition plate is arranged at the upper portion of the valve inner shell. An oil-gas diffusing hole communicated with the oil-gas separator is formed in the middle of the partition plate. The valve float element comprises a float element main part and a sealing component which can float vertically in the limited range. The sealing component comprises an upper sealing ring and a lower sealing ring which are integrally arranged. A central channel is arranged in the middle of the upper sealing ring and the middle of the lower sealing ring. The oil filling limiting stop valve has the beneficial effects that when a vehicle bumps or overturns, fuel in a fuel tank can be prevented from overflowing outwards.

Owner:孙达立

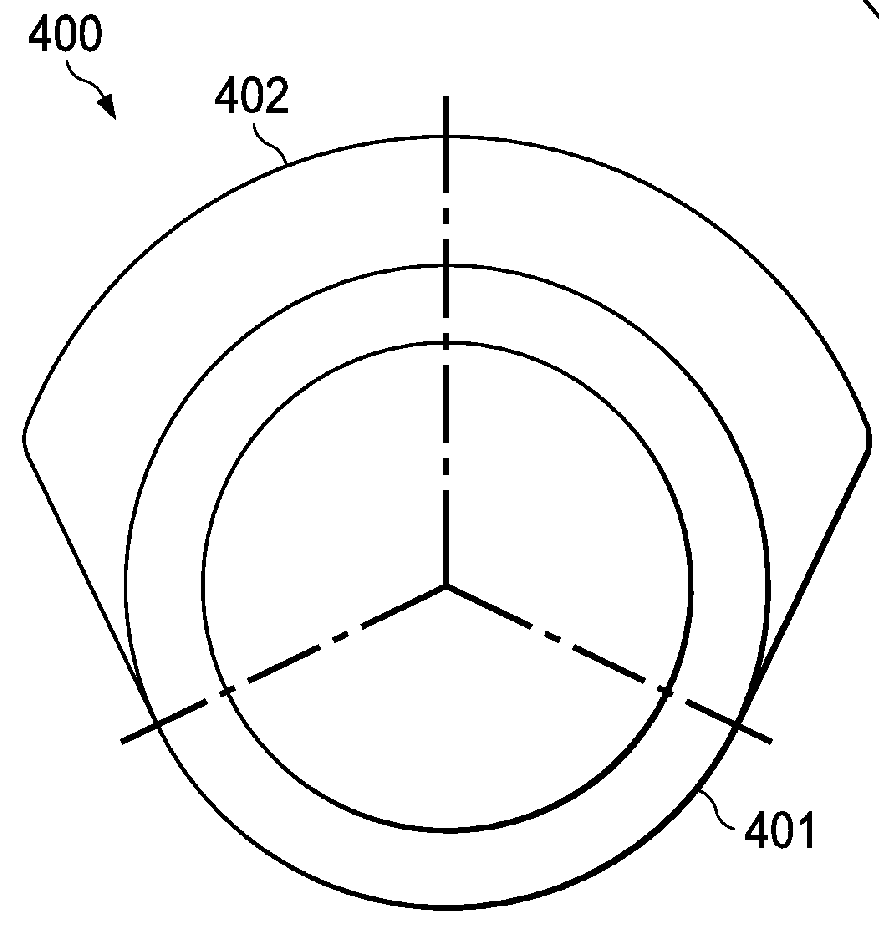

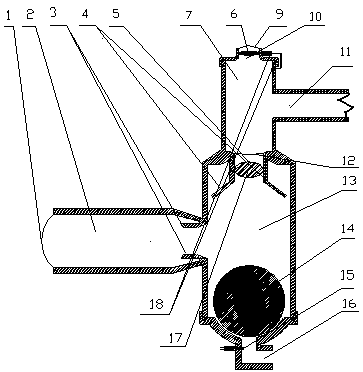

Overflow cut-off valve

The invention discloses an overflow cut-off valve. When a fuel tank is toppled, a valve floating core is in an inclined state; the weight of the lower part of the valve floating core is greater than that of the upper part of the valve floating core; the valve floating core is slightly staggered relative to an inner cavity of a valve casing; the valve floating core is not fixedly connected with a sealing element but a supporting pillar on the valve floating core provides a pivot for the sealing element and the sealing element can swing along the pivot; when the fuel tank is toppled, a return spring overcomes a resolution force of the gravity of the valve floating core to eject the valve floating core forwards and a sealing assembly leans against the lower end face of a ventilation hole; greater air pressure in the fuel tank acts on the inner side of the sealing assembly, so that the sealing assembly swings and a sealing surface on the sealing element is tightly attached to the ventilation hole. Compared with the traditional rubber valve with the fixed valve floating core, the overflow cut-off valve disclosed by the invention has the characteristics that the sealing element of the valve floating core can adjust the angle and seal the ventilation hole under the action of internal air pressure, and thus the fuel leakage of the fuel tank in a toppling state is further reduced.

Owner:孙达立

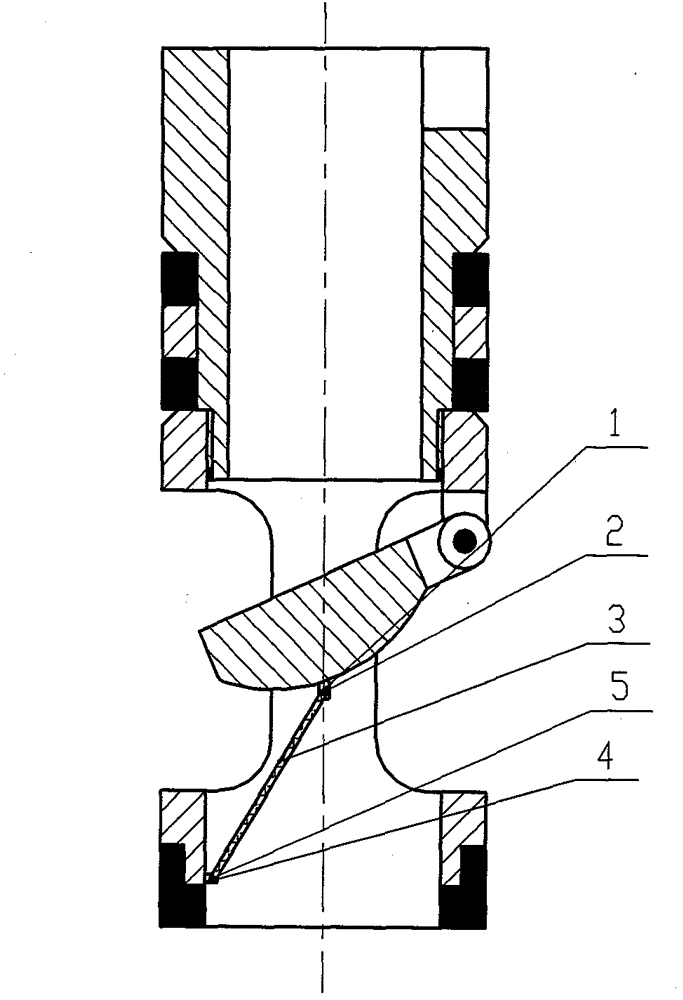

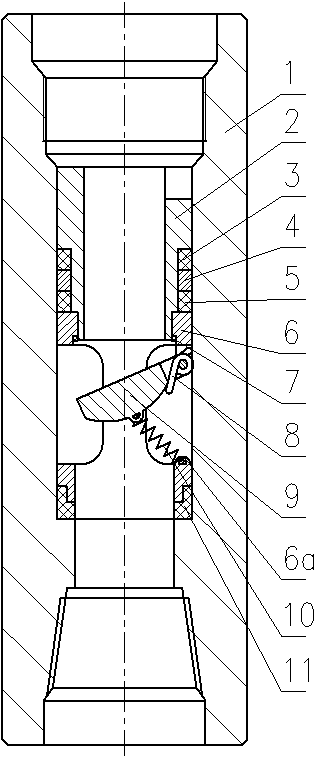

Pressure-transmitting pin snapping and fracturing automatic grouting valve float valve

The invention discloses a pressure-transmitting pin snapping and fracturing automatic grouting valve float valve. The automatic grouting valve float valve is characterized in that a float valve and a valve support mechanism are mounted in a float valve joint, a valve body seat of the float valve is hinged to a valve, the elasticity of a torsion spring on both the valve and the valve body seat enables the valve to close the valve body seat when the valve is in the free state; a support bar in a valve support mechanism, through which a valve hinge mount and a valve body hinge mount, supports the elasticity of the torsion spring to enable that the valve and the valve body seat can not be closed; the valve of the float valve is in the semi-opened state to form a fluid flow passage, so that the purpose of automatic grouting can be achieved. When the pump is started after tripping, or well kick occurs in a pipe, and the force acted on the valve by fluid once the blowout slurry is reversely sprayed is larger than the tensile strength of the support bar, the support bar is snapped and fractured, and the valve, which loses the supporting force after pump stop or during well kick and blowout to be in the free state, is promptly closed under the action of the resultant force of the spring force and the like. As pressure transmitting small holes are obliquely formed in the valve, pressure of fluid inside and outside the valve after the valve is closed is transmitted.

Owner:慕武

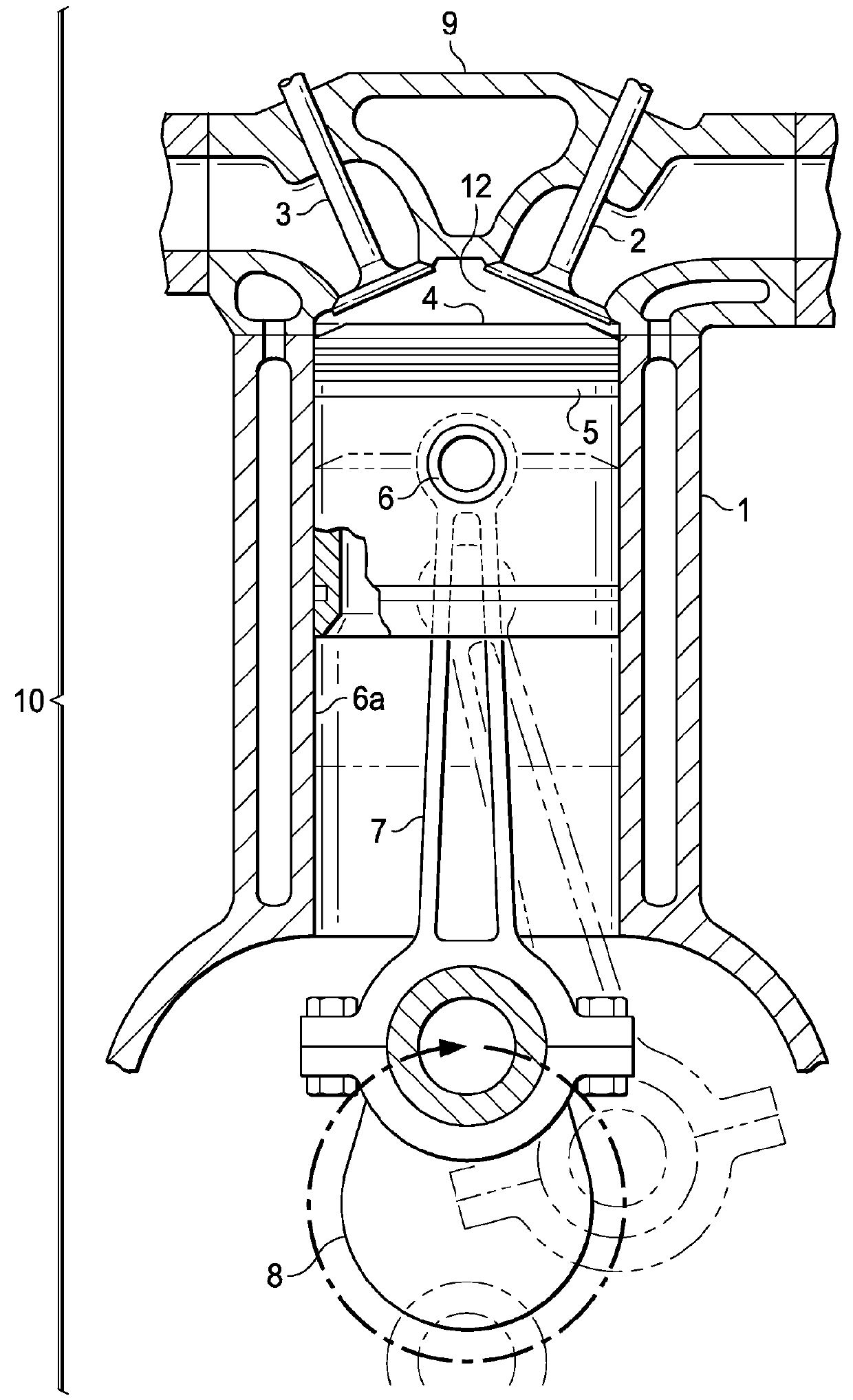

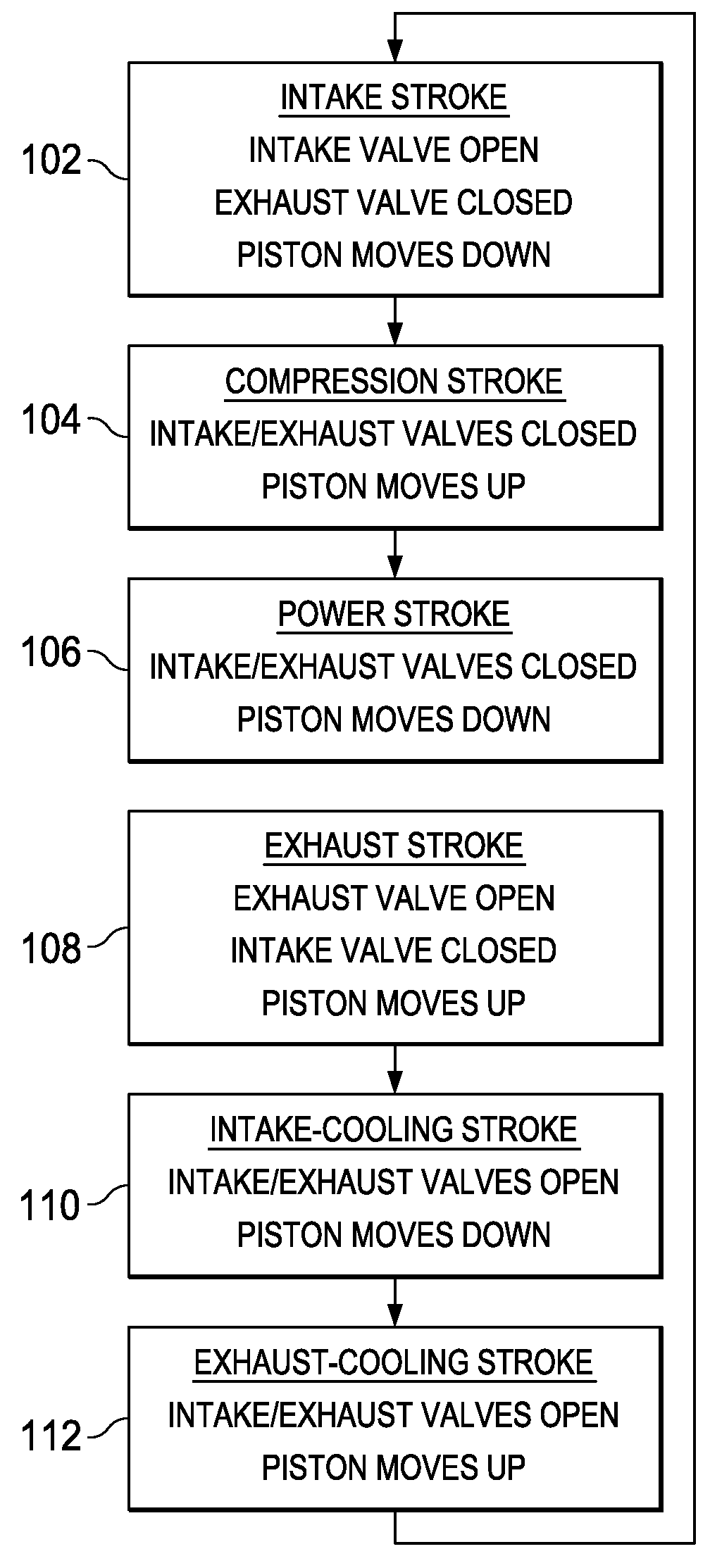

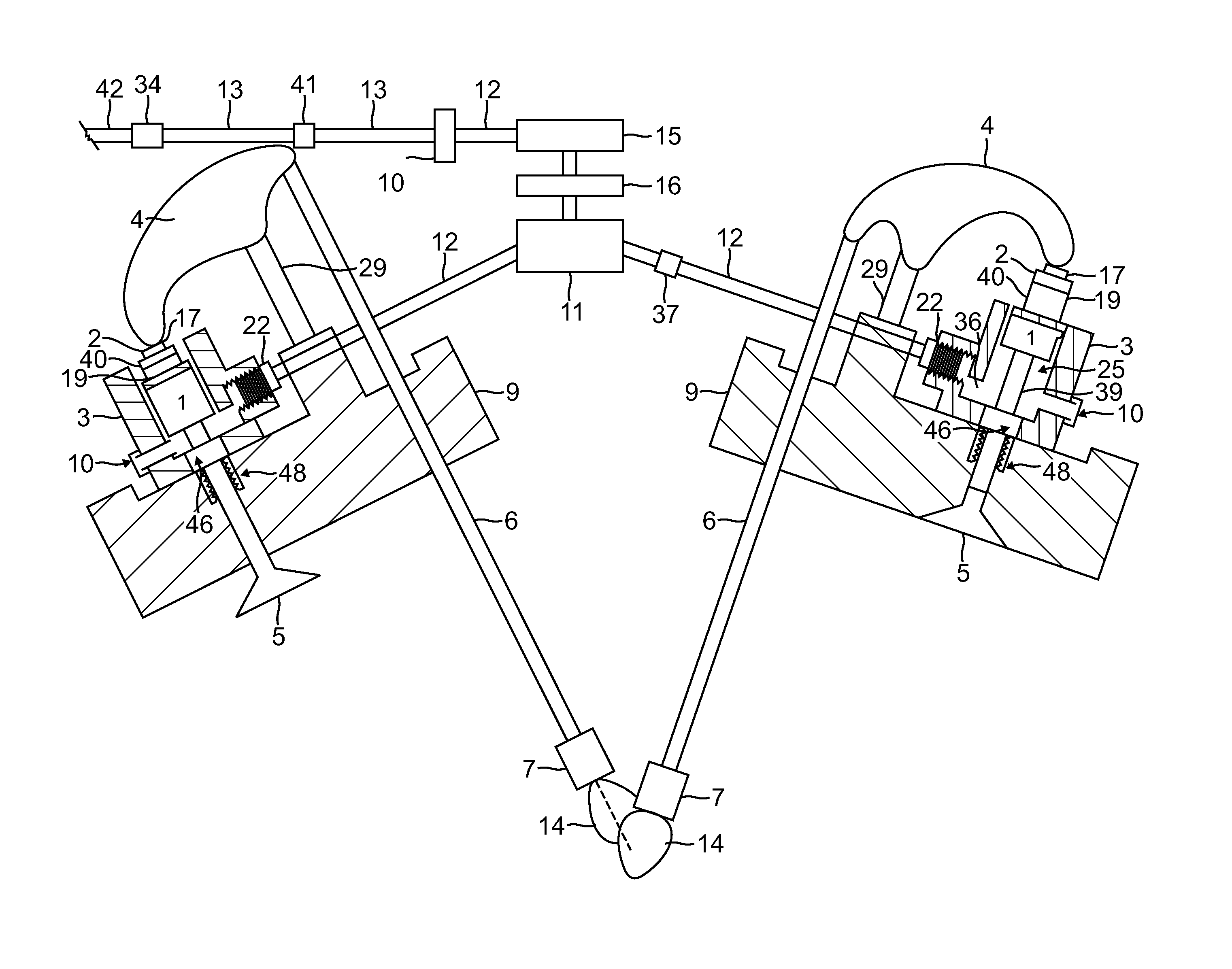

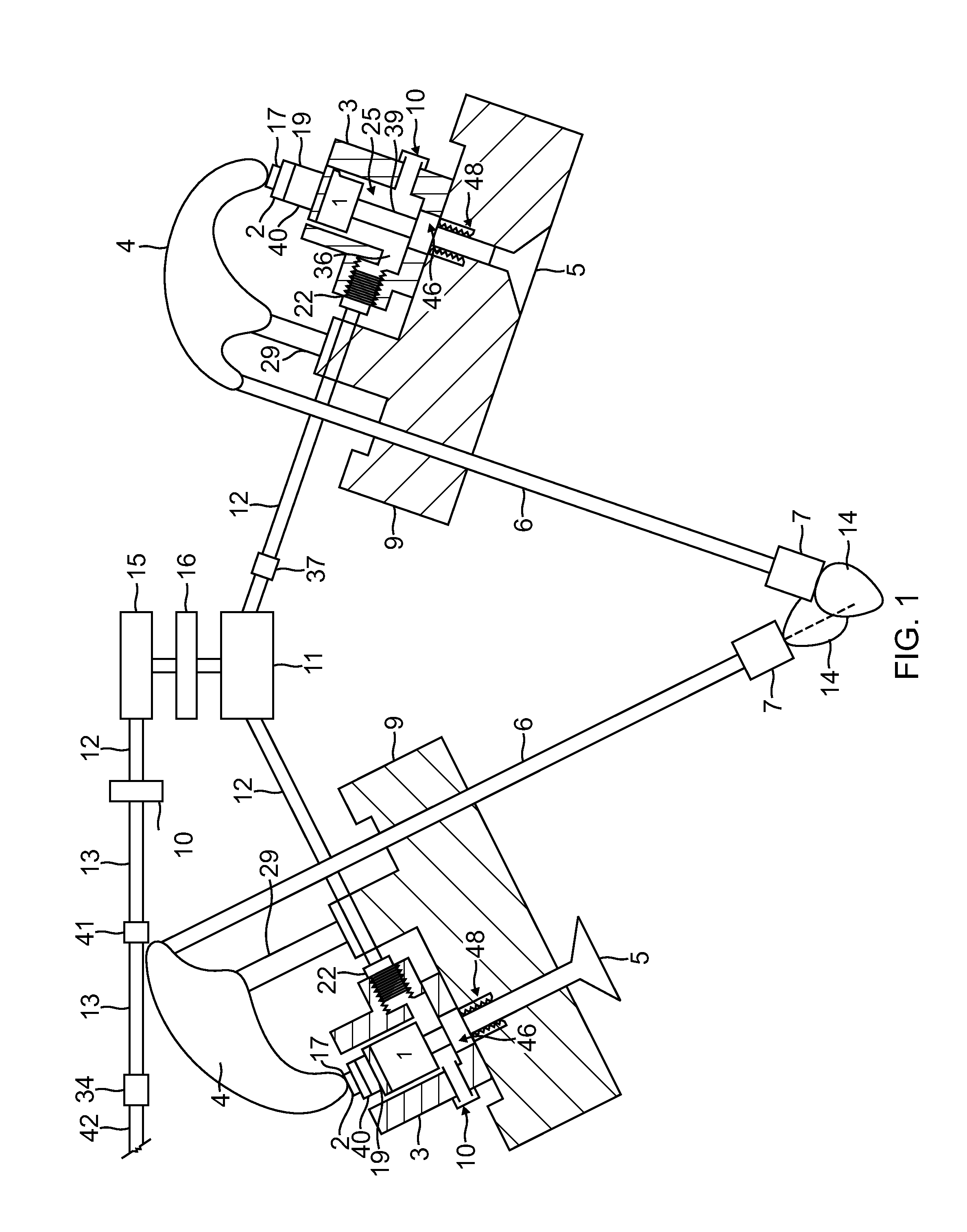

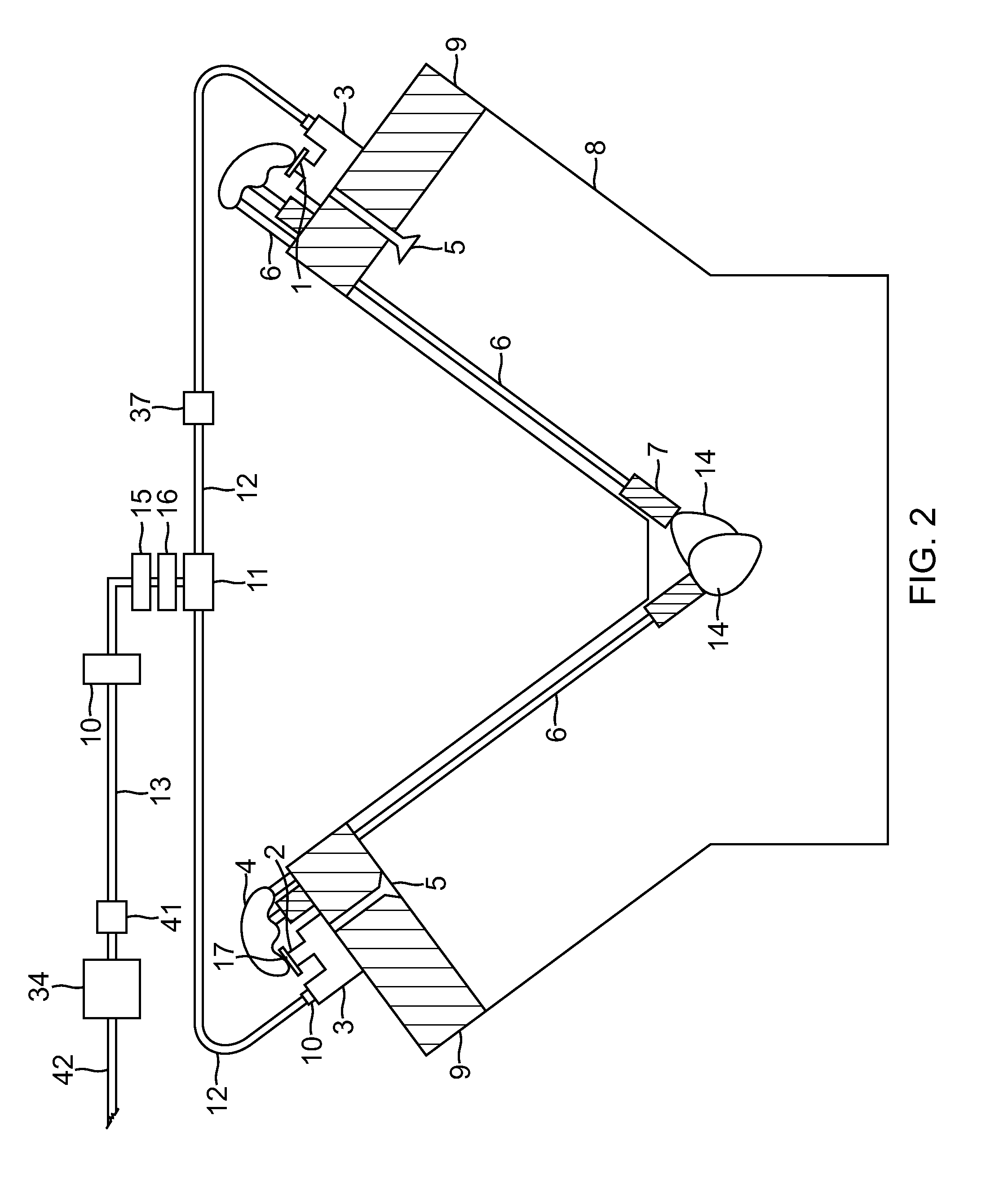

Six Stroke Internal-Combustion Engine

InactiveUS20160032821A1Increase the compression ratioImprove efficiencyElectrical controlInternal combustion piston enginesCombustionFuel efficiency

A method for modification and improvement in internal combustion engine systems utilizing six strokes (1. an intake stroke, 2. a compression stroke, 3. a power stroke, 4. an exhaust stroke, 5. an intake-cooling stroke and 6. an exhaust-cooling stroke) and incorporating changes to the camshaft lobes and valve train timing providing for a 3:1 camshaft to crankshaft ratio allowing for higher revolutions per minute, lower idling speeds, reduced valve float and smoother operation. The system provides for more efficient fuel combustion during the power stroke, which extends past bottom dead center thus increasing power, fuel efficiency, and greatly reduces harmful emissions. The additional fifth and sixth strokes provide for intake and exhaust cooling. The system demonstrates increased reliability, efficiency, and a cooler operating environment while operating with various fuels.

Owner:AMERICAR ENGINE

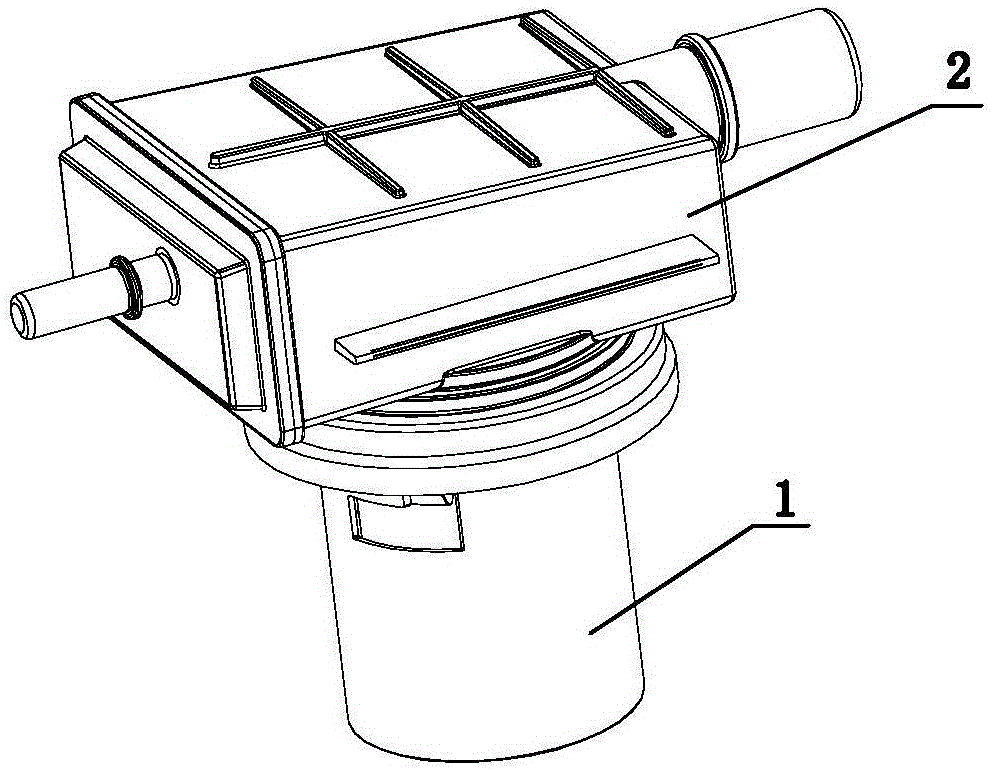

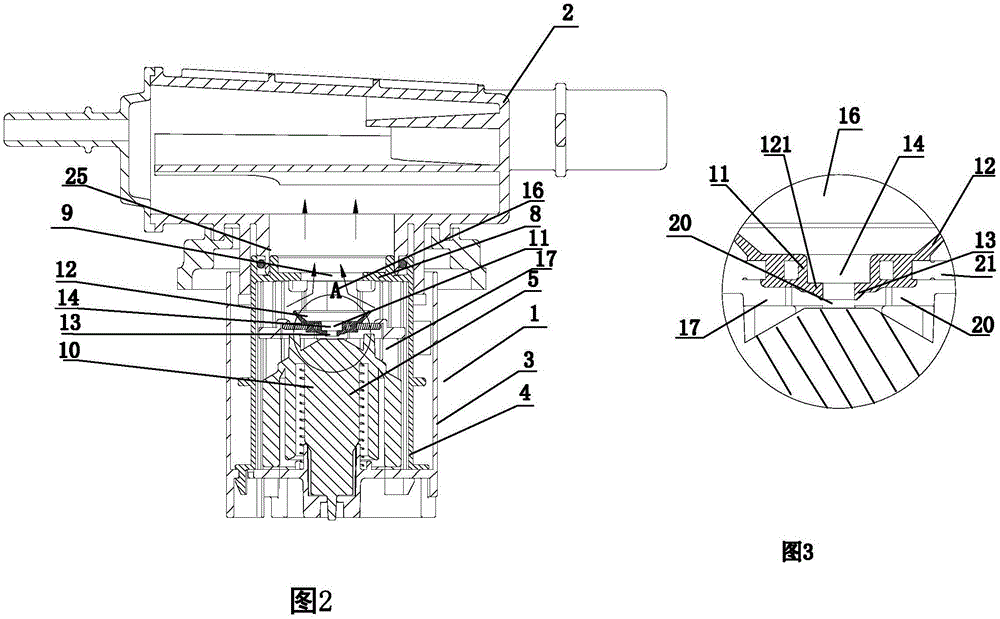

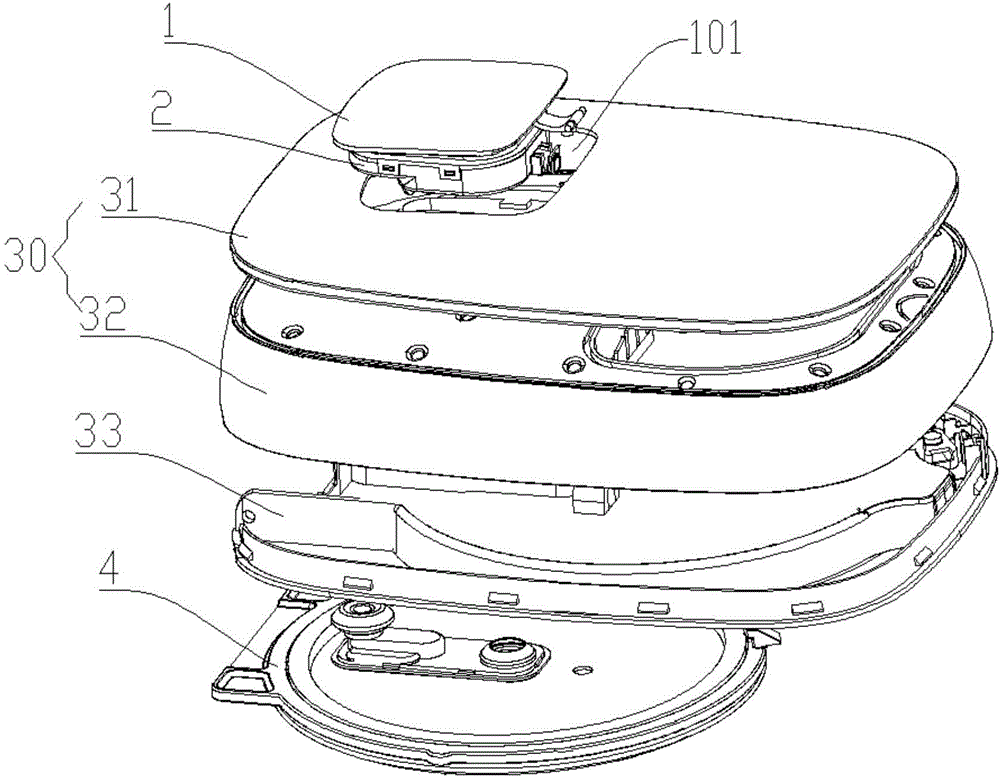

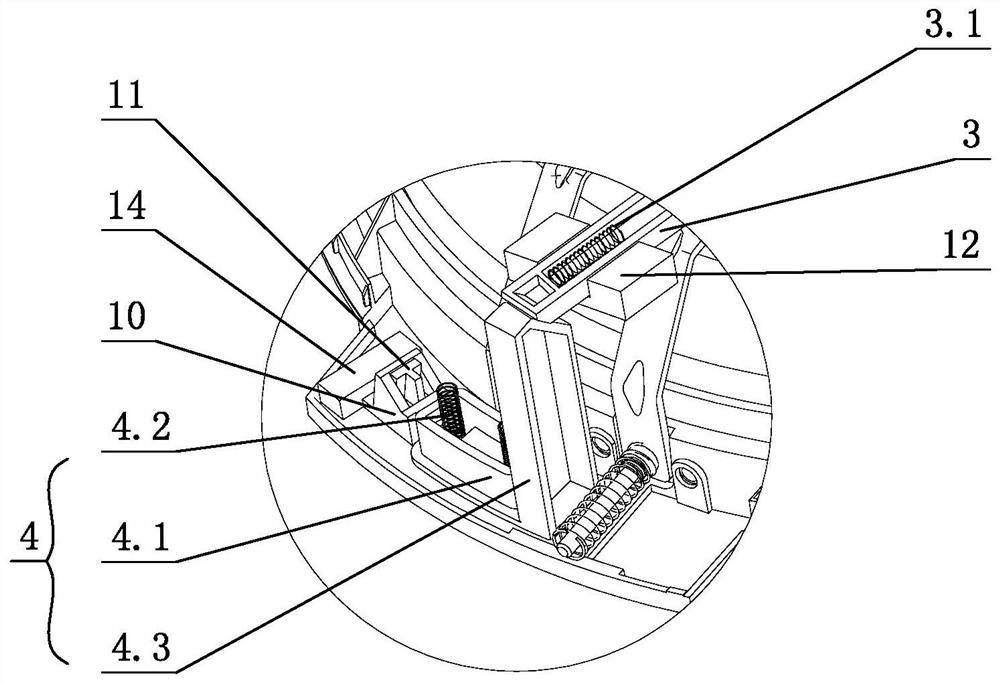

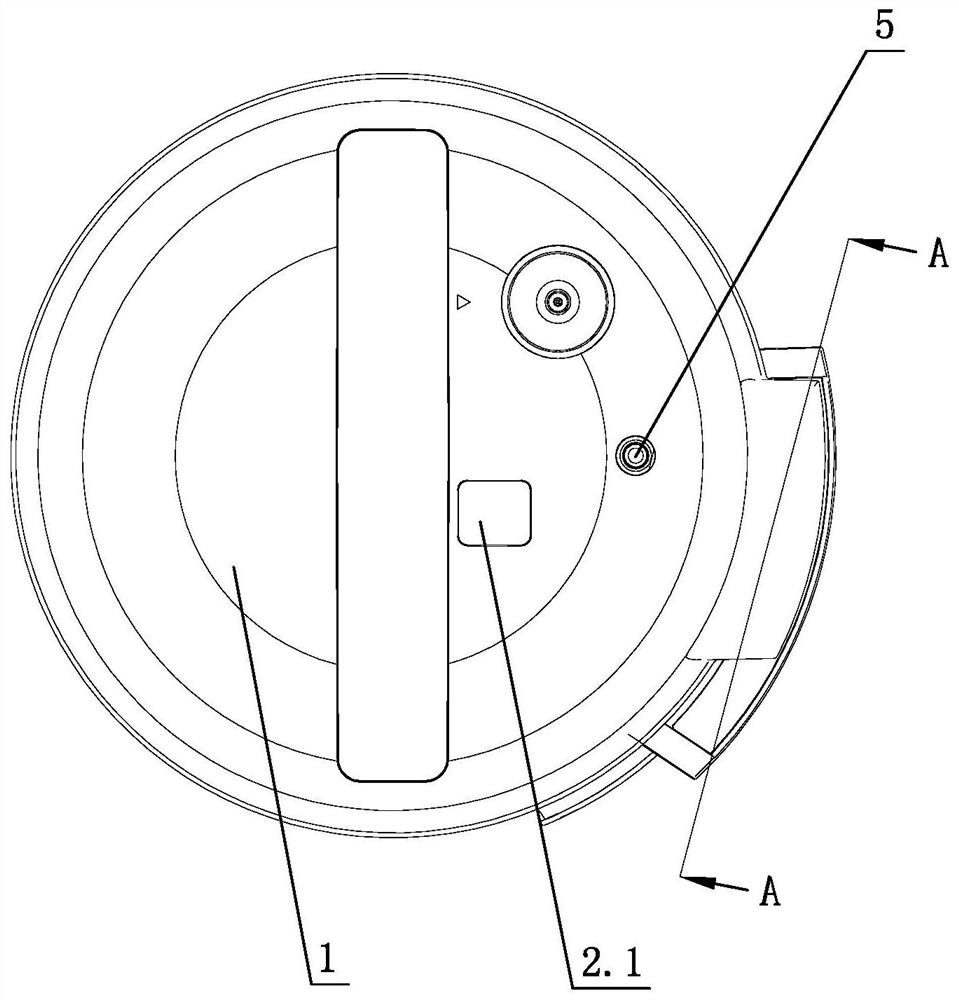

Steam valve assembly and cooking apparatus provided with the same

InactiveCN106037501ABe careful of burnsAvoid spillingCooking-vessel lids/coversValve floatEngineering

The invention provides a steam valve assembly which can be applied in a pot cover of a cooking apparatus. The steam valve assembly comprises a valve body provided with an air outlet, and a driving assembly; the valve body is movably installed on the pot cover and can move about between a first position and a second position under the driving of the driving assembly for closing or opening the air outlet. According to the invention, through the movable arrangement of the valve body, on one hand, the ability of conducting vapor outward can be changed according to the temperature inside the pot; one the other, the whole steam valve floats upwards during exhausting which prompts users to be careful of being burnt. The invention also provides a cooking apparatus comprising the steam valve.

Owner:HONGYANG HOME APPLIANCES

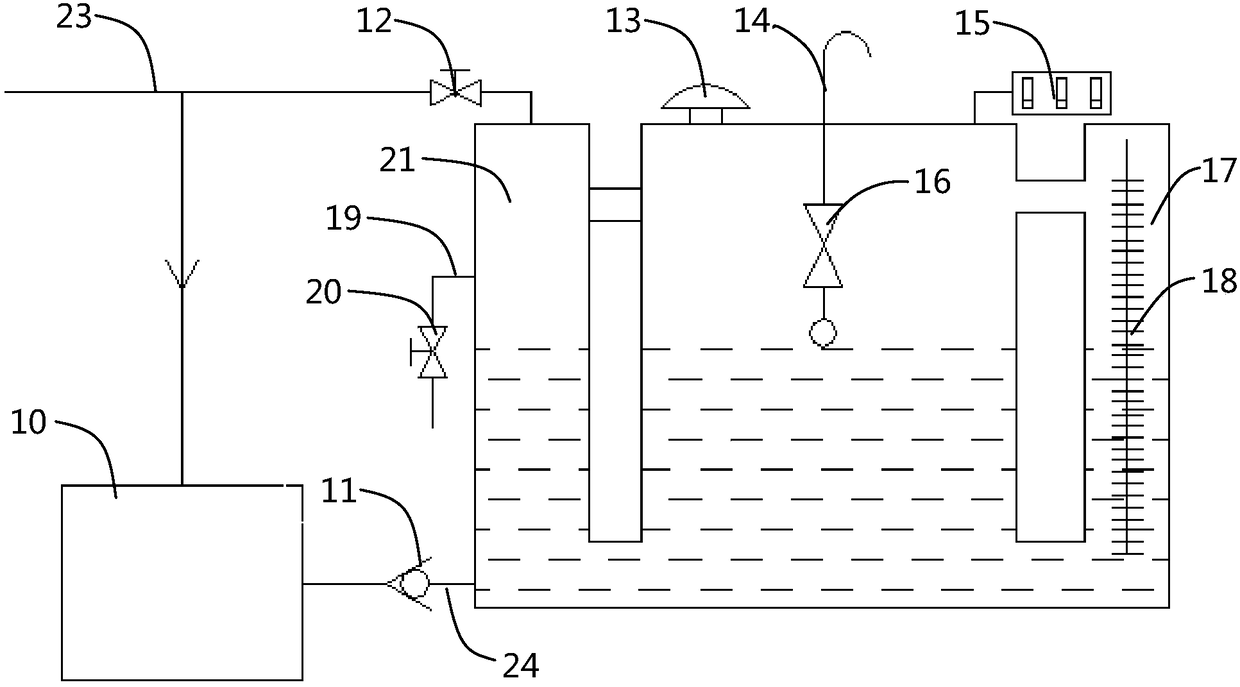

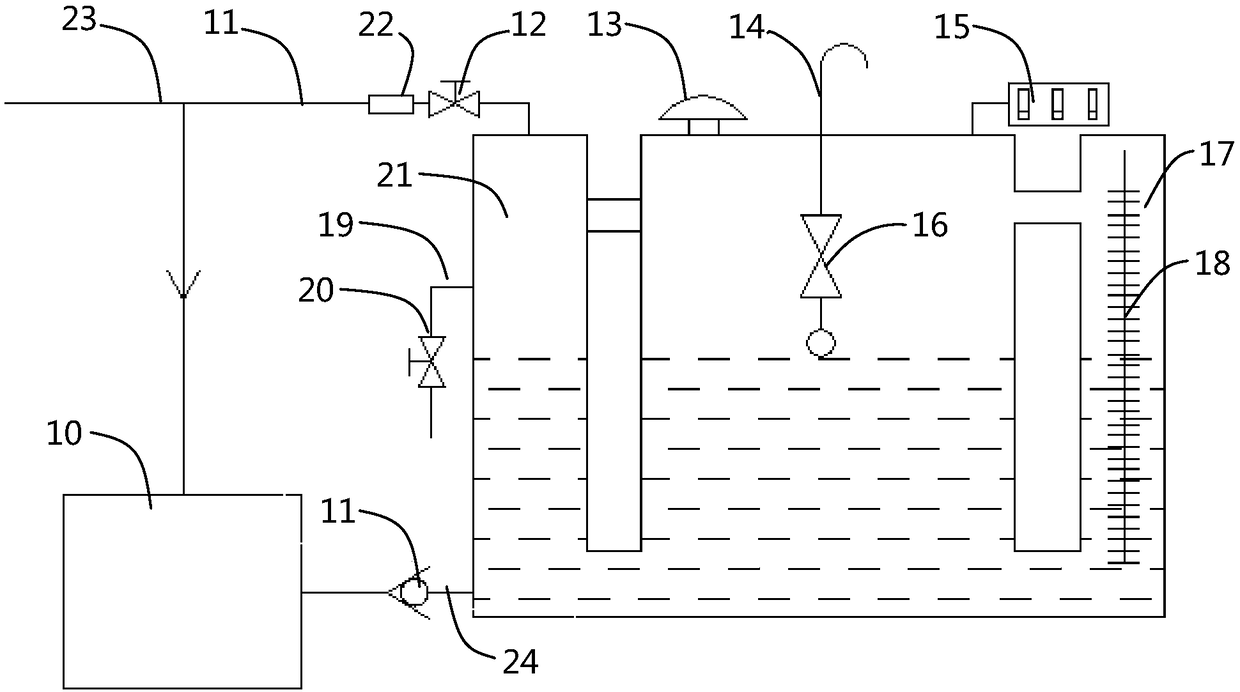

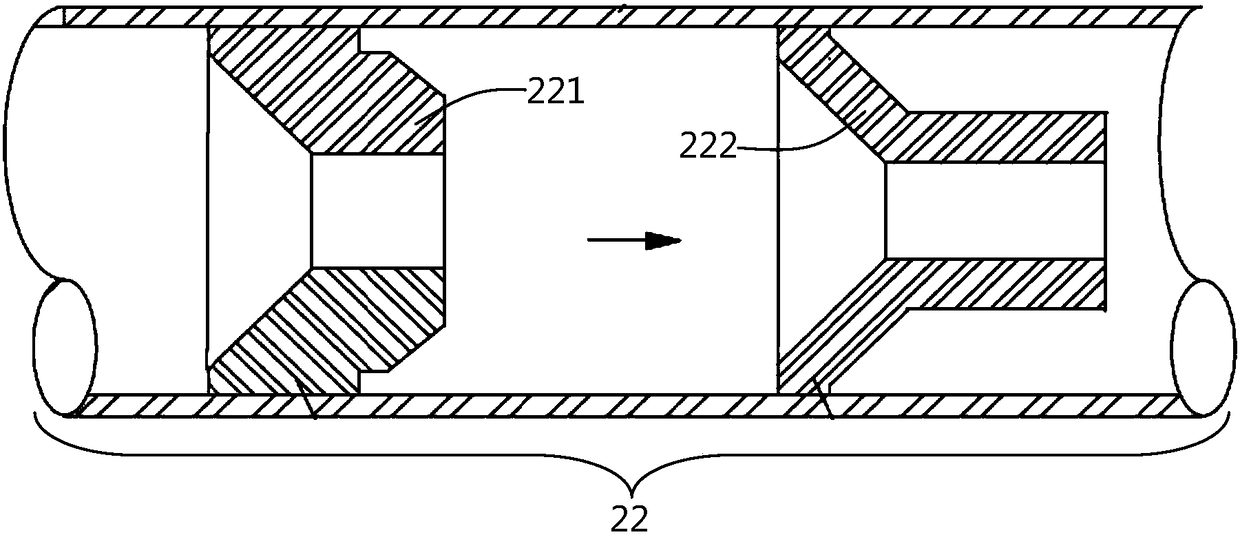

Continuous water supply device, water drinking system and industrial Hu sheep breeding equipment

PendingCN108308053AGuaranteed water supplyPrevent backflowAnimal watering devicesWater drinkingValve float

The invention discloses a continuous water supply device, a water drinking system and industrial Hu sheep breeding equipment and belongs to the technical field of breeding. The continuous water supplydevice comprises a water injection tank and a ventilation mechanism, a water incoming pipe is arranged at the top of the water injection tank, and a water outgoing pipe is arranged at the bottom of the water injection tank and connected with a water fountain; the ventilation mechanism comprises a ventilation elbow and a floater sealing valve, the lower end of the ventilation elbow extends into the water injection tank, and the floater sealing valve floats on water-drinking liquid level and abutted against the lower end of the ventilation elbow. The continuous water supply device is composed of the water injection tank and the ventilation mechanism and arranged on a water incoming pipeline of the water fountain, a certain amount of water is stored in the water injection tank, and incomingwater is updated constantly in daily use, so that the water in the water injection tank is flowing water; once water supply in the water incoming pipe is stopped, liquid level of the water injection tank descends in a short time, so that the floater sealing valve of the ventilation mechanism is disconnected with the ventilation elbow, pressure in the water injection tank is increased, and normal water supply of the water fountain is ensured.

Owner:和县和顺牧业有限公司

Pressure limiting valve and cooking utensil

The invention provides a pressure limiting valve and a cooking utensil. The pressure-limiting valve comprises a valve seat provided with an air inlet hole; a valve cover which covers the valve seat, wherein a cavity is defined by the valve cover and the valve seat, at least two mounting holes are formed in the top end of the valve cover, and the mounting holes are communicated with the cavity; andfloat valves, wherein at least two float valves are mounted in the at least two mounting holes in a one-to-one correspondence manner, exhaust channels are formed in the float valves, the float valvesare provided with sealing positions for blocking the mounting holes and exhaust positions for communicating the exhaust channels with the cavities, and the float valves float up and down in the axialdirection of the mounting holes so as to be switched between the sealing positions and the exhaust positions. Due to the fact that the number of the float valves is two or more, each float valve is provided with the corresponding exhaust channel, exhaust is conducted on the cooking utensil through the multiple exhaust channels at the same time, cold air in the cooking utensil can be rapidly exhausted out, cold air residues in the cooking utensil can be effectively reduced, and the cooking efficiency of the cooking utensil is conveniently improved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Pressure-transmitting supporting automatic grouting valve float valve

InactiveCN103306638APrevent backflowAvoid the Risk of BlowoutsWell/borehole valve arrangementsSealing/packingFree stateSpring force

The invention discloses a pressure-transmitting supporting automatic grouting valve float valve. The automatic grouting valve float valve is characterized in that a float valve is mounted in a float valve joint, a valve supporting device is welded in the float valve, a valve body seat of the float valve is hinged to a valve, the elasticity of a torsion spring on both the valve and the valve body seat enables the valve to close the valve body seat when the valve is in the free state, the supporting device balances the spring force for automatically closing the valve-type float valve according to the principle that a supporting spring has a certain supporting force (the spring force can be adjusted through changing the size of the spring) and the in-pipe flowing force generated by pressure difference inside and outside fluid in a well, and a supporting bar enables the valve to be always in the tightly open state to form a channel so as to achieve the purpose of automatic grouting. When well kick or blowout occurs in the pipe, the valve enables the supporting bar to compress the supporting spring under the action of fluid flowing into the pipe, the supporting bar retracts into a supporting box, and the valve is closed to achieve the purpose of a check valve. As pressure-transmitting small holes are obliquely formed in the valve, the pressure of liquid inside and outside the valve after the valve is closed is transmitted.

Owner:慕武

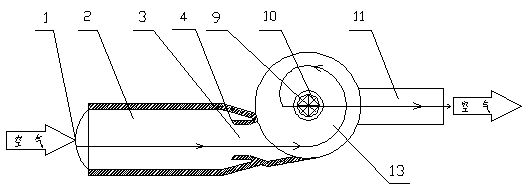

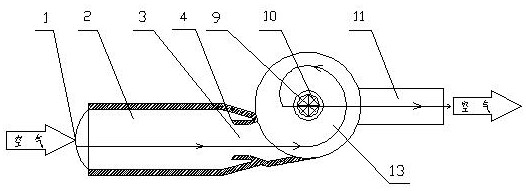

Motor vehicle internal combustion engine speed-sensitive linear automatic supercharging air supply device

ActiveCN107917021AImprove linearityBurn completelyMachines/enginesAir intakes for fuelEggshellFuel oil

The invention provides a motor vehicle internal combustion engine speed-sensitive linear automatic supercharging air supply device. The air supply device is provided with a supercharging chamber communicating with an air inlet pipe of an internal combustion engine. An air inlet of the supercharging chamber faces against the wind generated by a motor vehicle during advancing, and the air pressure in the supercharging chamber and the air supply amount of the internal combustion engine are automatically increased and reduced along with change of the vehicle speed. The supercharging chamber can beof a combined structure, or an eggshell type structure, a whistle type structure, or a horn type structure or a straight pipe type structure. The combined supercharging chamber is composed of a supercharging chamber body and an auxiliary supercharging chamber body on the upper portion. A valve grid is arranged between the supercharging chamber body and the auxiliary supercharging chamber body. Anair pressure valve is arranged on the valve grid and is limited between guide rods to float up and down. The upper end of the auxiliary supercharging chamber body is provided with an auxiliary air inlet used for being sealed when the air pressure valve floats up. An internal combustion engine air inlet pipe communicates with the auxiliary supercharging chamber body. A pipe serves as the air inletand goes into the supercharging chamber body in the tangential direction. Air is fed into the internal combustion engine through the wind pressure generated by the motor vehicle during running to increase the air supply amount and promote sufficient burning of fuel oil. The power of the internal combustion engine is increased. Oil consumption is reduced. Carbon deposit of the internal combustionengine is reduced. The purchase cost and the maintenance cost of the motor vehicle are reduced.

Owner:HONGHE COLLEGE

High Tension Valve Spring and Valve Float Eliminator

Owner:BARBER MICHAEL

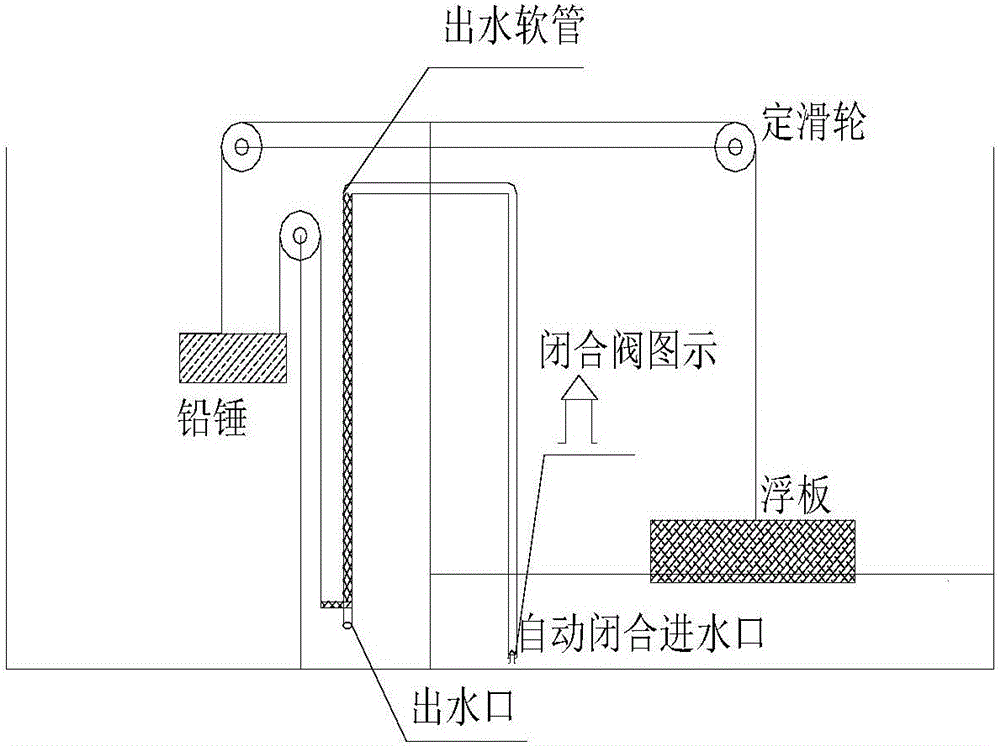

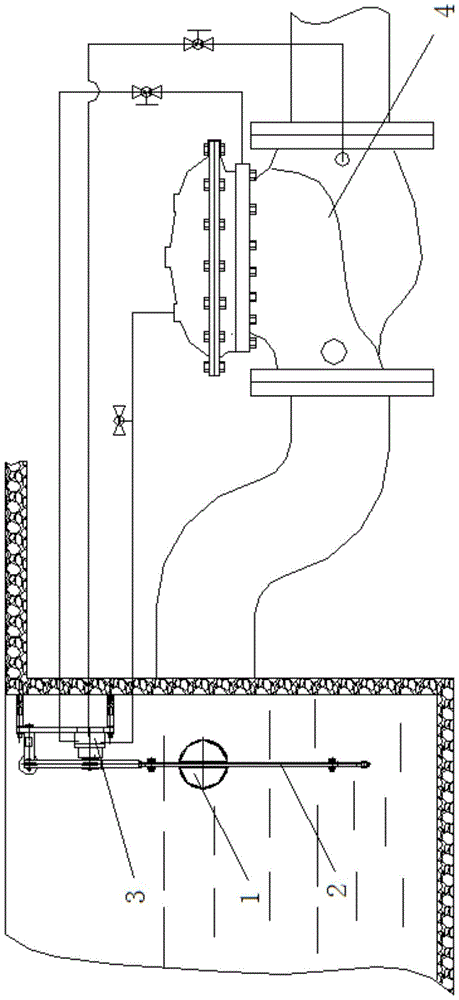

Design for balancing automatic water distribution system

InactiveCN106649997ASolve the problem of uneven loadBalanced and stable water distributionGeometric CADSpecial data processing applicationsSiphonConstructed wetland

The invention belongs to an innovative design for balancing an automatic water distribution system. The system structure comprises a floating plate, a fixed pulley, a rope, a plumb bob, an airbag and a siphon; the sewage flows into the system from a water inlet, and then flows out the system from a water outlet after passing through the siphon; an automatic closing valve is arranged at the water inlet; when the water volume in a water inlet pool is evacuated, the closing valve is automatically closed since the suffered floating force is declined, thereby controlling the liquid in the siphon to flow out; when a water level in the pool is risen, the valve floats upward and is automatically opened to form the siphonage, thereby enabling the water flow to flow out in balance. The automatic water distribution system is an environment-friendly equipment system without energy consumption, and can be extensively applied to constructed wetlands, oxidation ponds, land sheetflood and other sewage ecological purification engineering.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

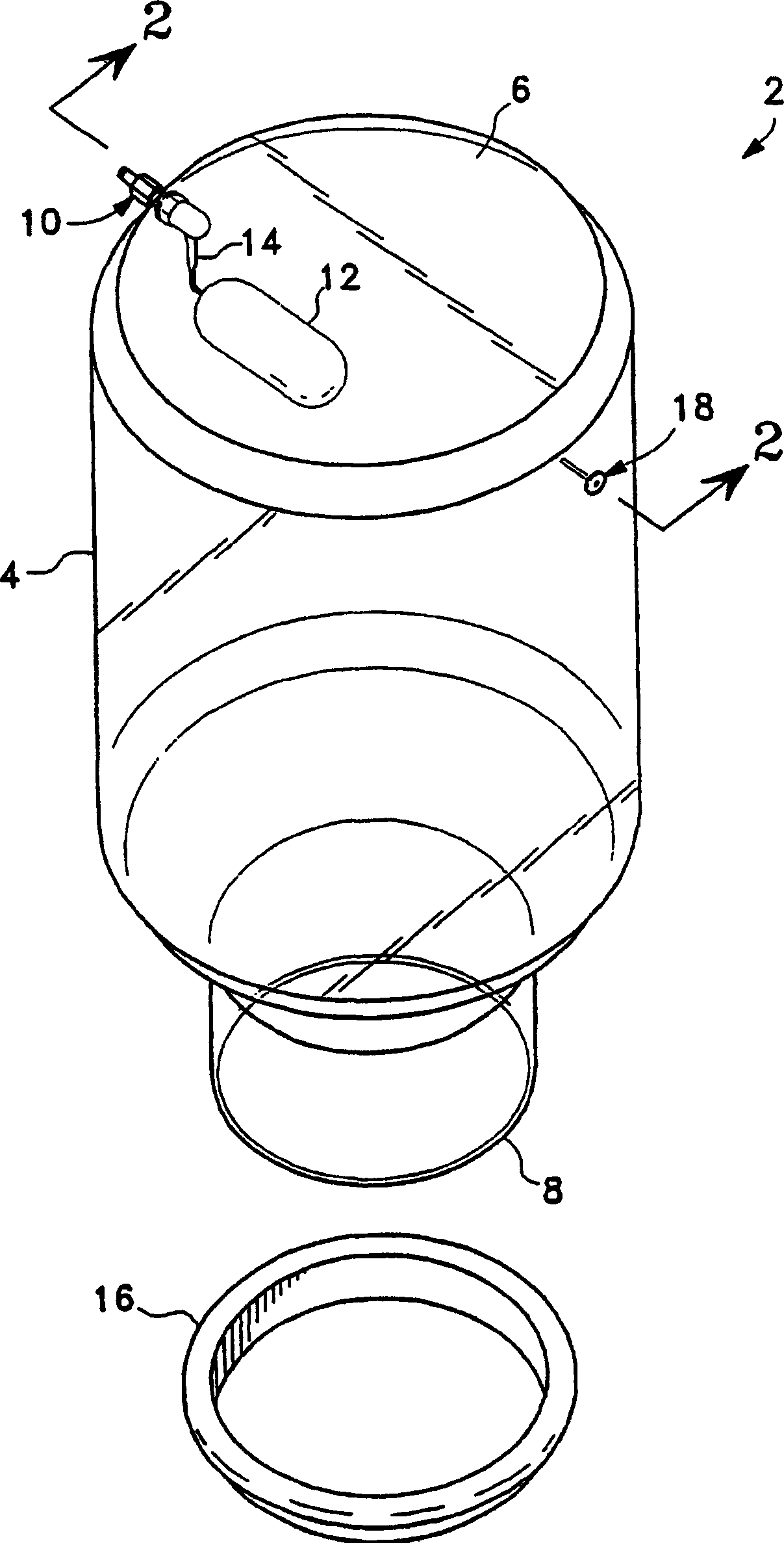

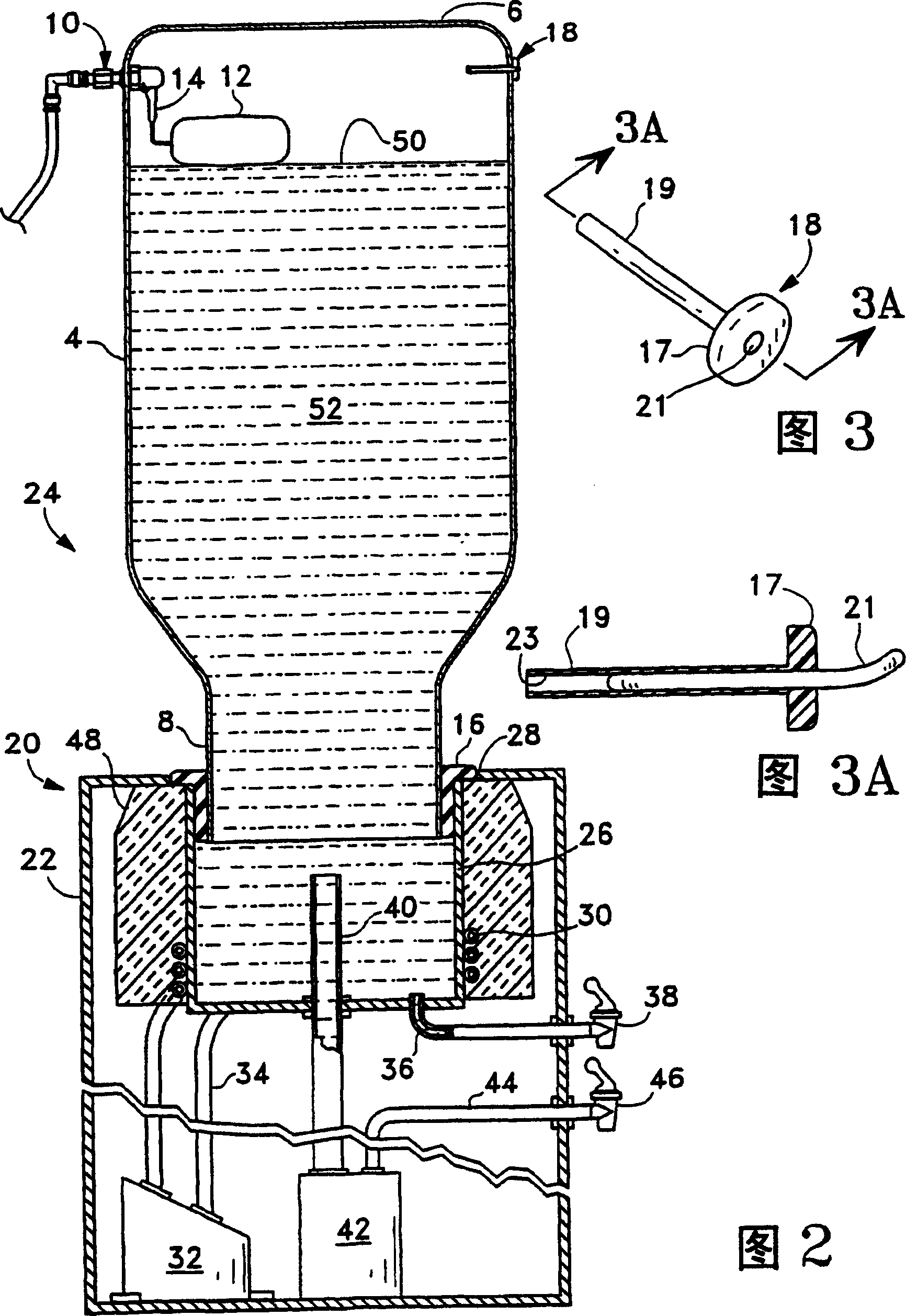

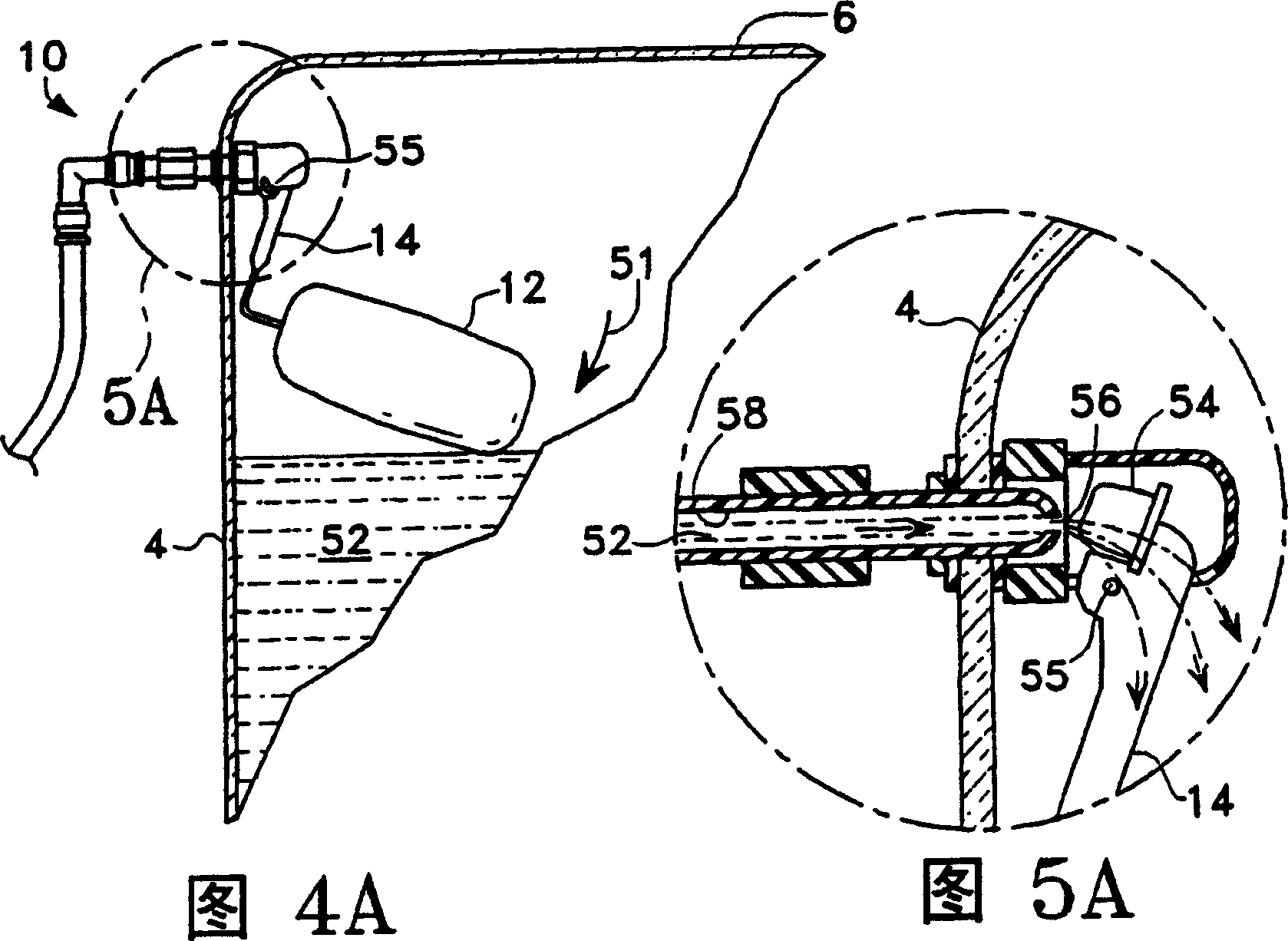

Continuous-flow drinking fluid dispenser

InactiveCN1281476CFew moving partsSmall sizeLiquid flow controllersLiquid transferring devicesValve floatBuoy

A drinking fluid dispenser (24) includes a bottle (4) positioned on a dispenser base (20). Mounted inside the bottle (4) is a valve (10) closely connected to the float (12) via an actuator arm (14). The valve (10) is located above the fluid (52) of the bottle (4) and is connected to a continuous flow fluid source. During normal operation, when the liquid level (50) of the fluid (52) rises and falls in the bottle (4), the float (12) floating on the fluid (52) by buoyancy closes and opens the valve respectively. The dispenser also has a pressure tube (18) with a hole through said bottle (4) above the fluid (52) of said bottle, thereby maintaining atmospheric pressure inside the bottle (4).

Owner:ACCESS GLOBAL INC

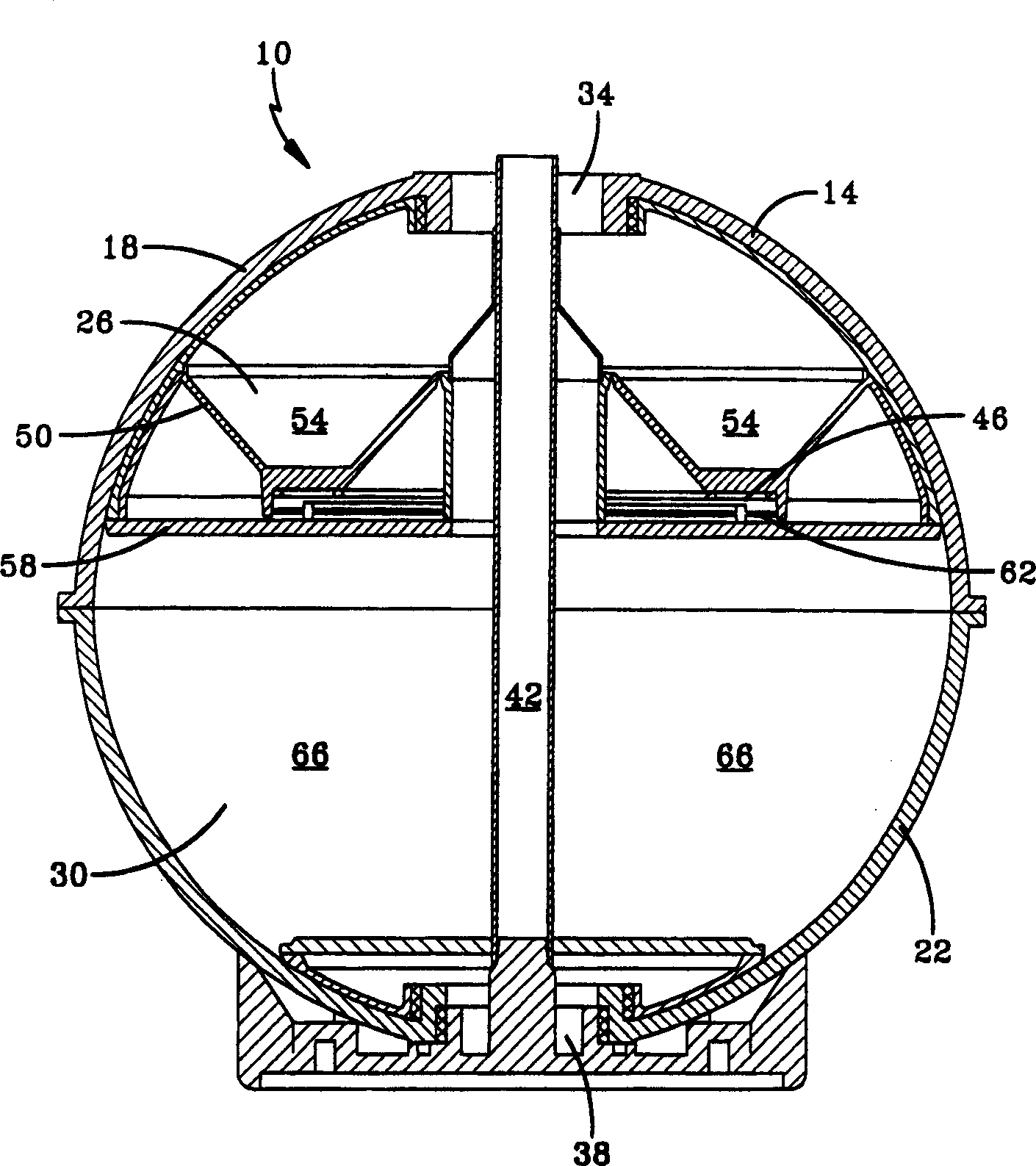

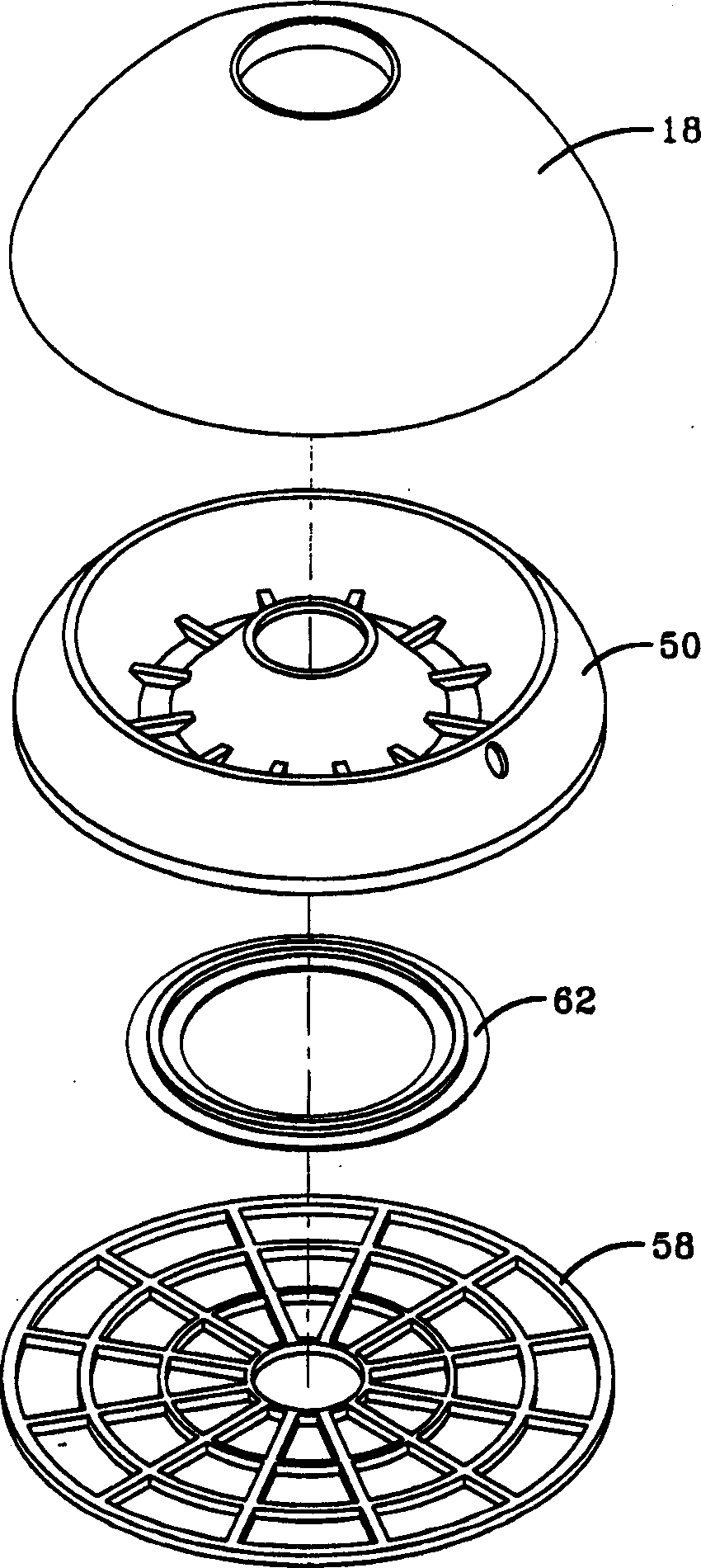

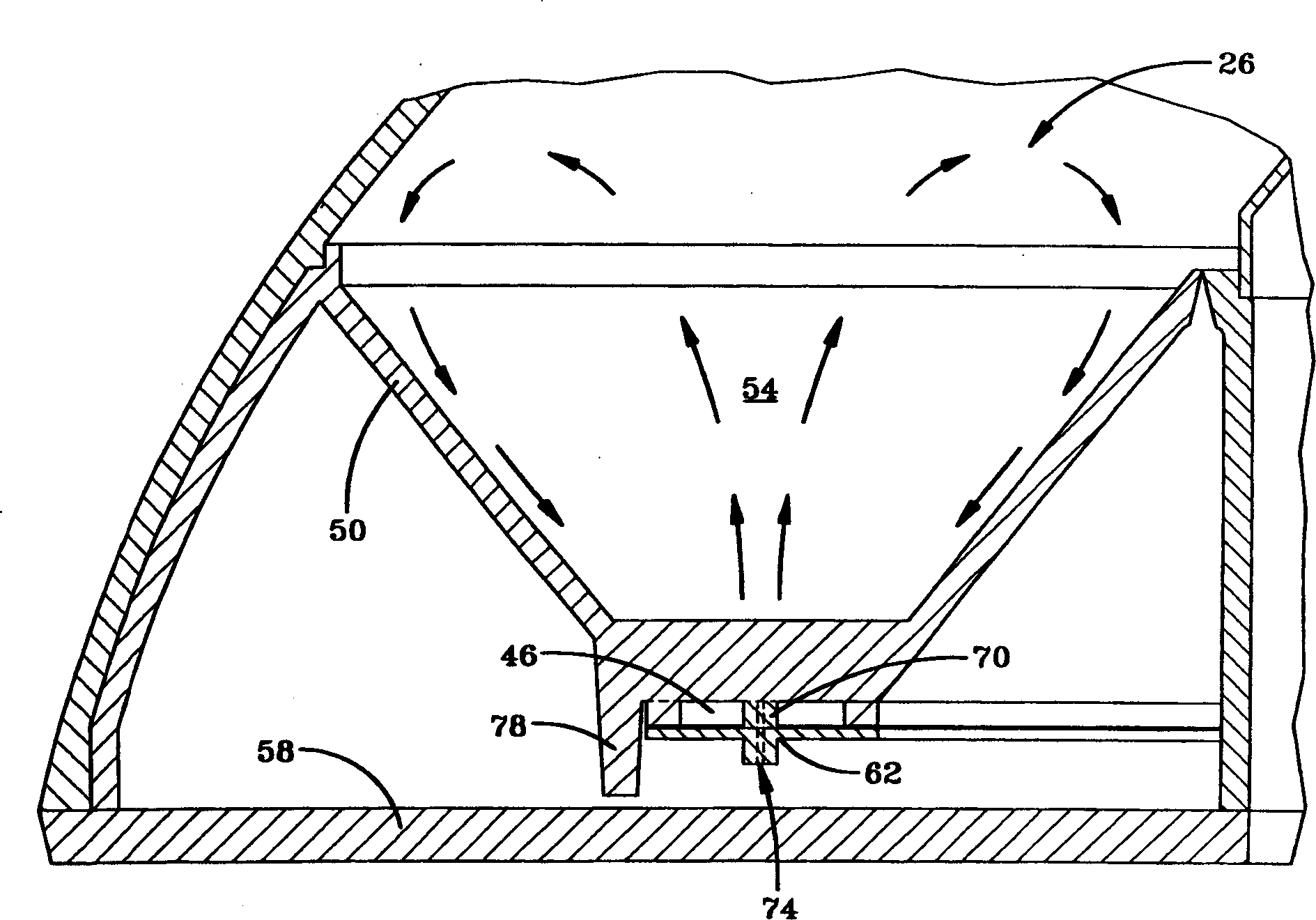

Water softener tank

InactiveCN1347336AWash thoroughlyAchieve regenerationIon-exchange column/bed processesIon-exchanger regenerationOxidation-Reduction AgentWater flow

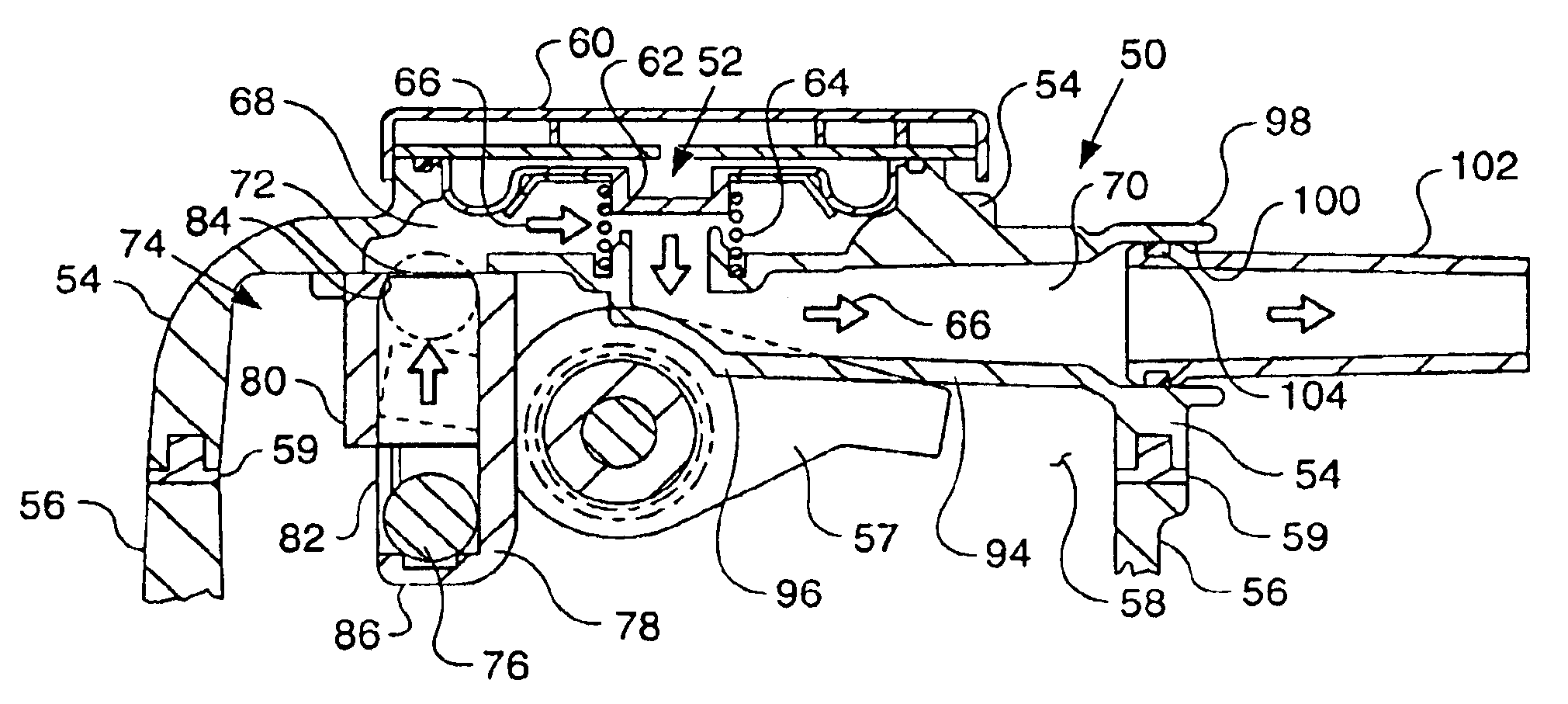

A two-chambered water softener tank (10) with a bidirectional valve (62) for controlling the flow of water between the chamber for use with a water softener is disclosed. The tank includes an outer shell (14), an upper chamber (26) located within the outer shell containing a redox medium (54), a lower chamber (30) located within the outer shell and beneath the upper chamber that contains an ion exchange resin (66), a first port (34) allowing water to flow into the upper chamber, a second port (38) allowing water to flow into the lower chamber, and a third port (46) for allowing water to flow between the upper chamber and lower chamber. The water softener tank also includes a bidirectional valve engageable with the third port for regulating flow of water through the third port from the upper chamber to the lower chamber during service of the water softener and from the lower chamber to the upper chamber during regeneration of the water softener. The bidirectional valve remains open as water flows from the upper chamber to the lower chamber. The bidirectional valve floats upwards to restrict the flow of water through the third port from the lower chamber to the upper chamber during regeneration, thereby creating a high pressure flow of water during the regeneration of the water softener to clean the redox medium, such as KDF.

Owner:弗罗美蒂克系统公司

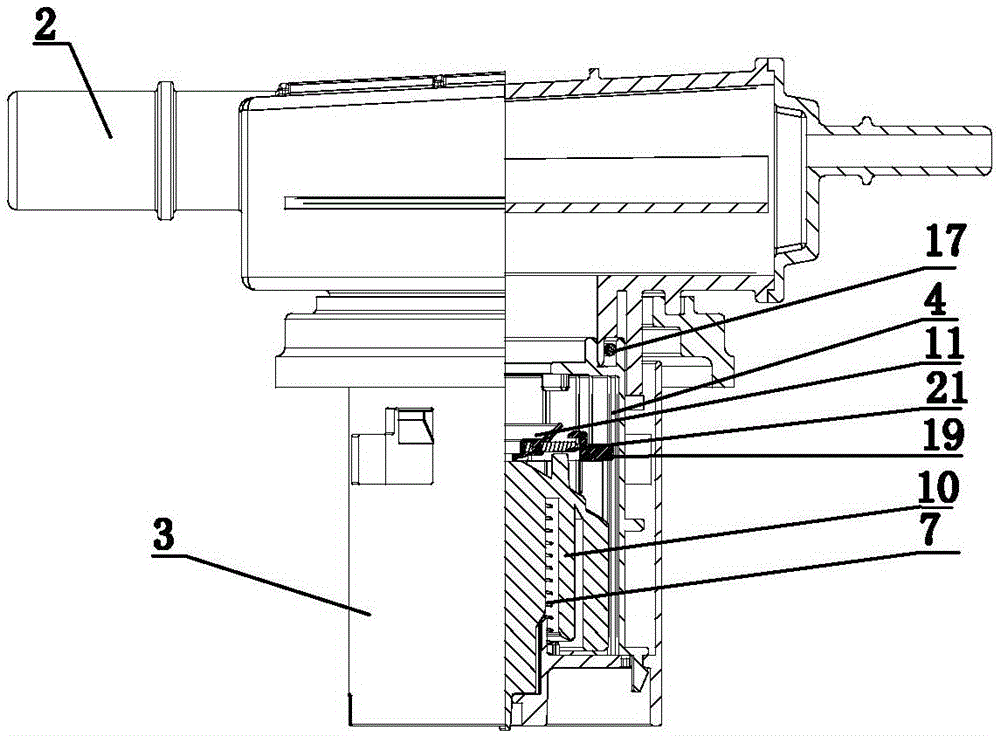

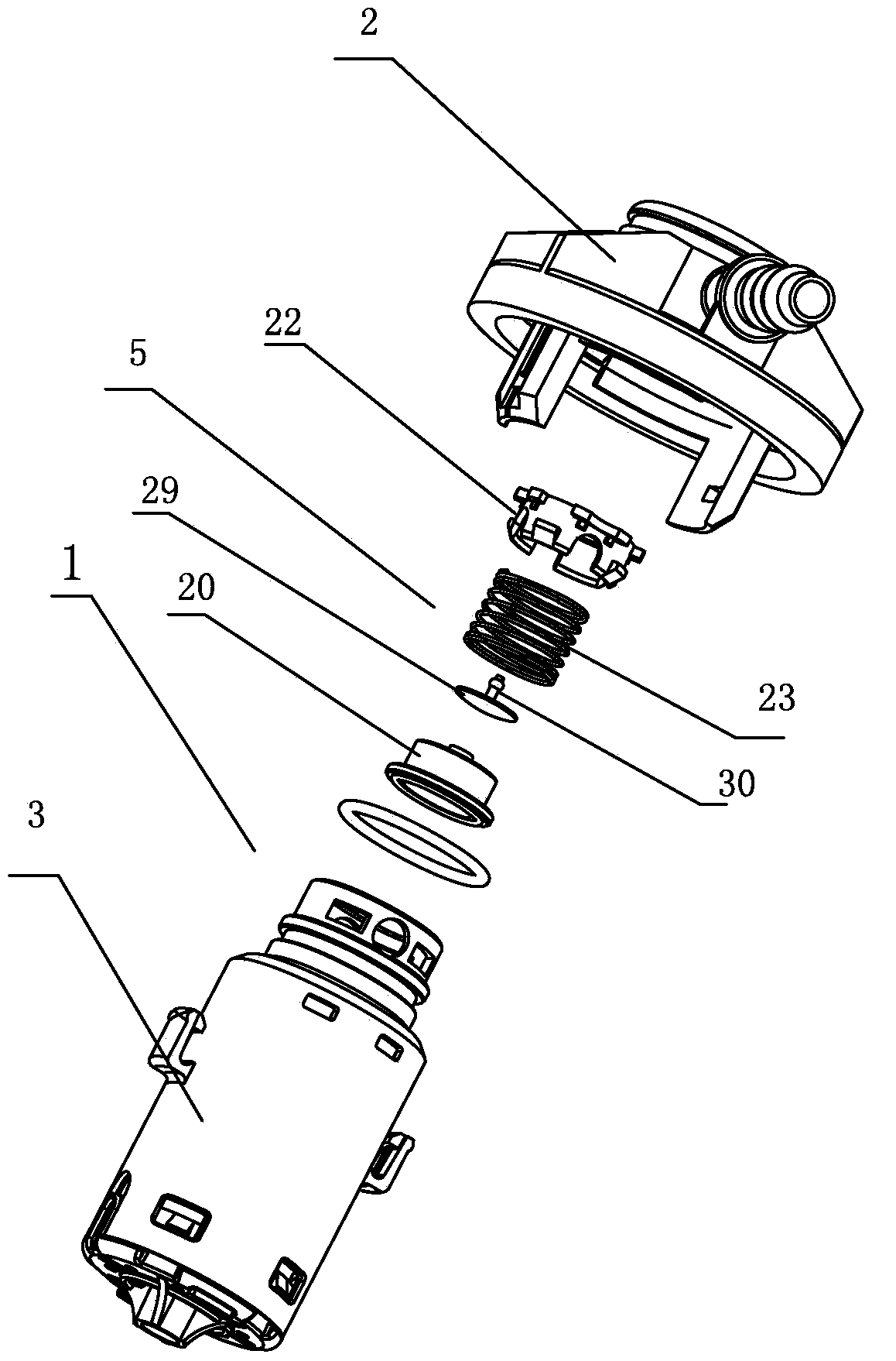

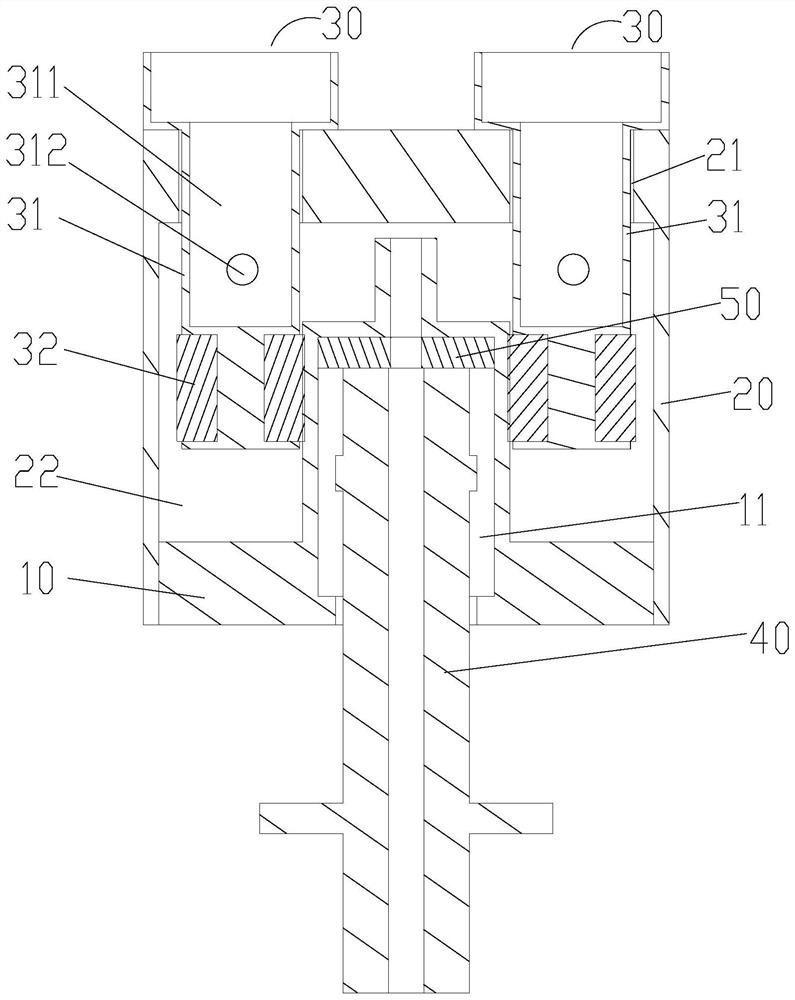

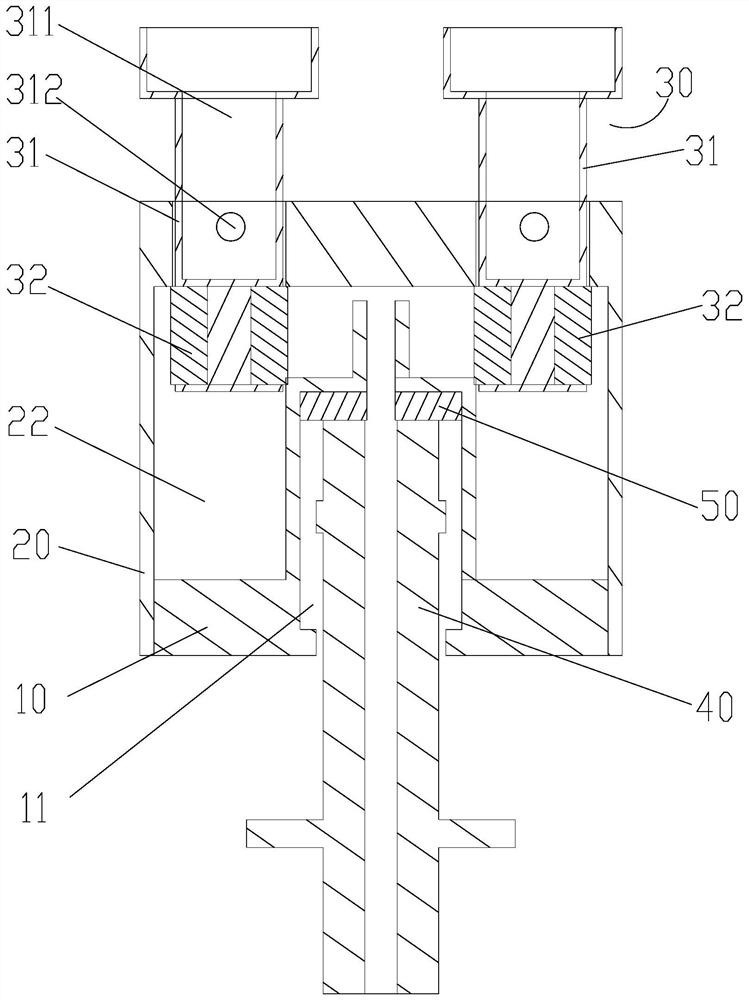

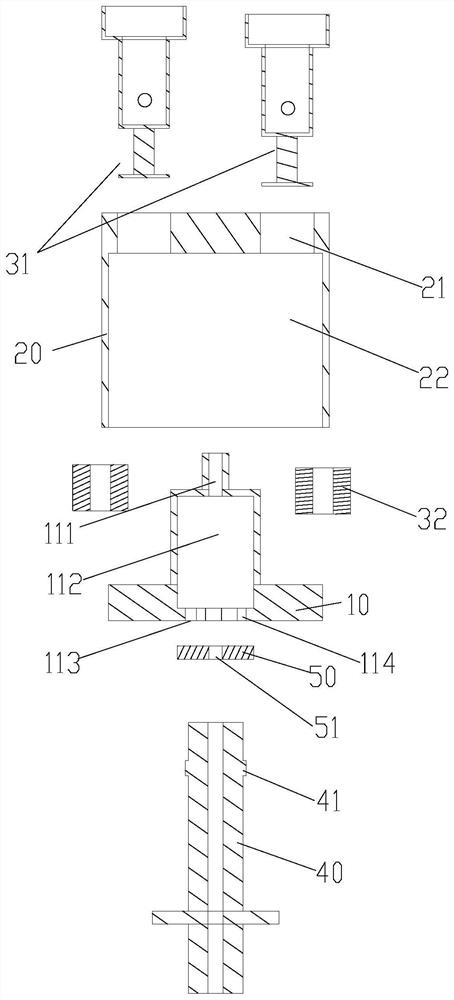

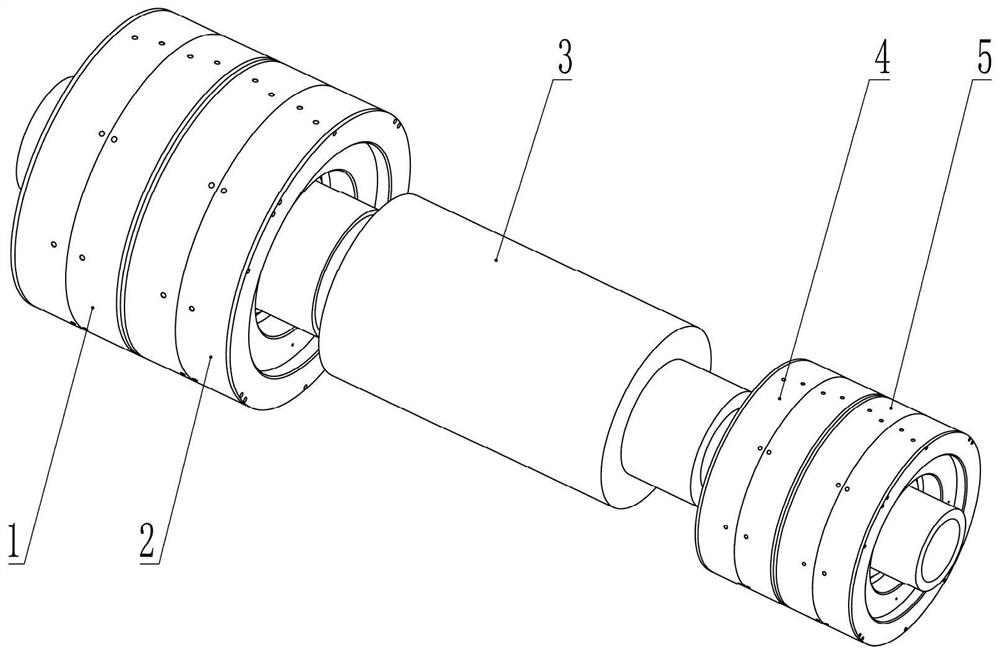

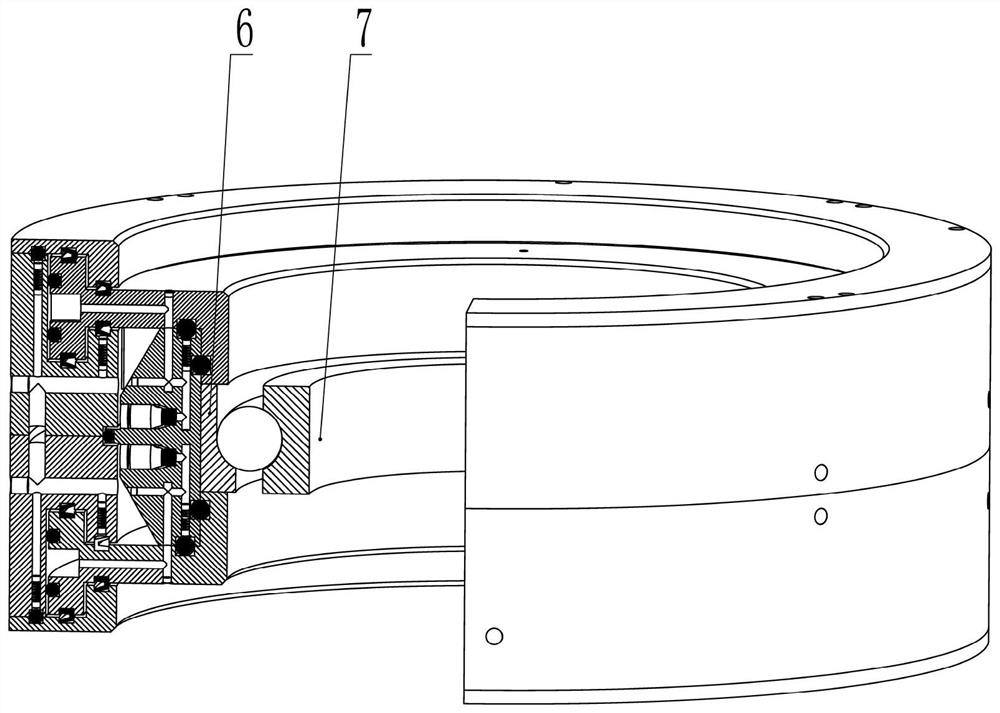

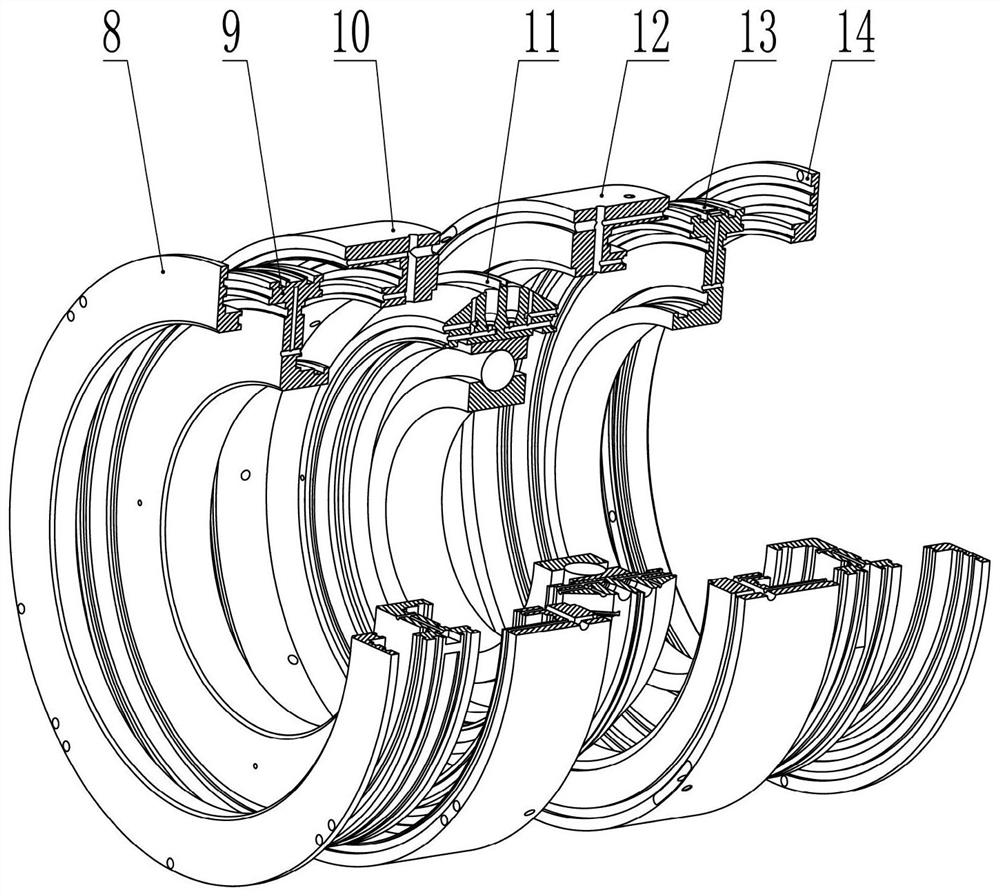

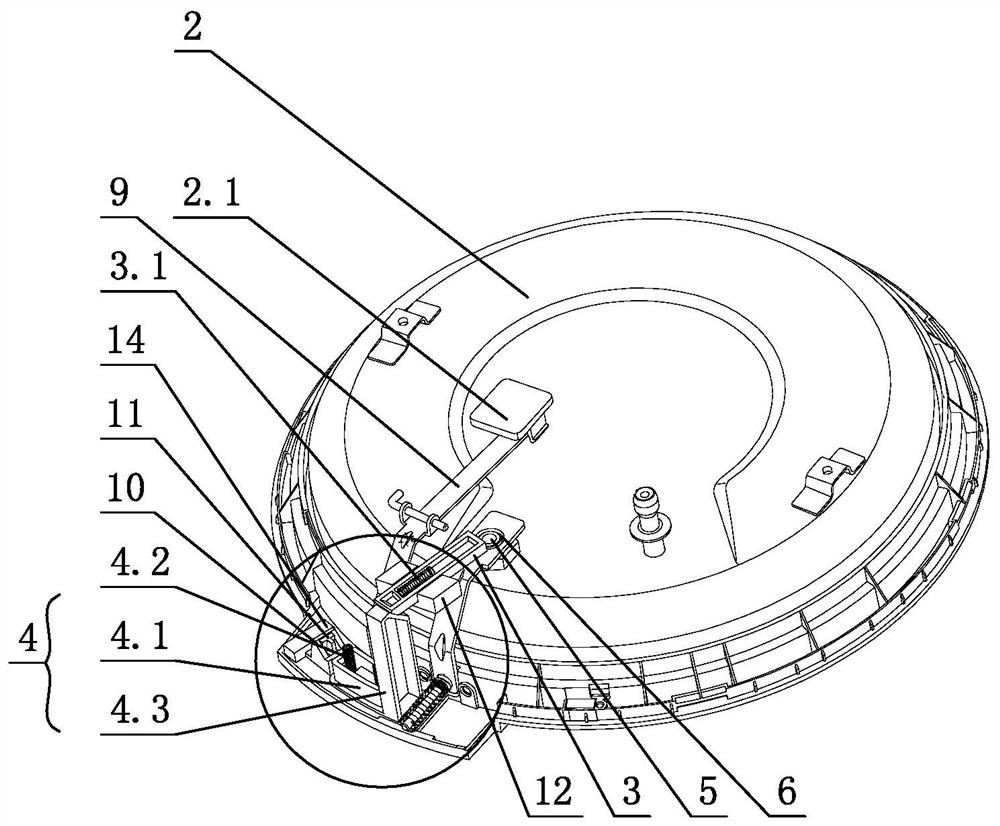

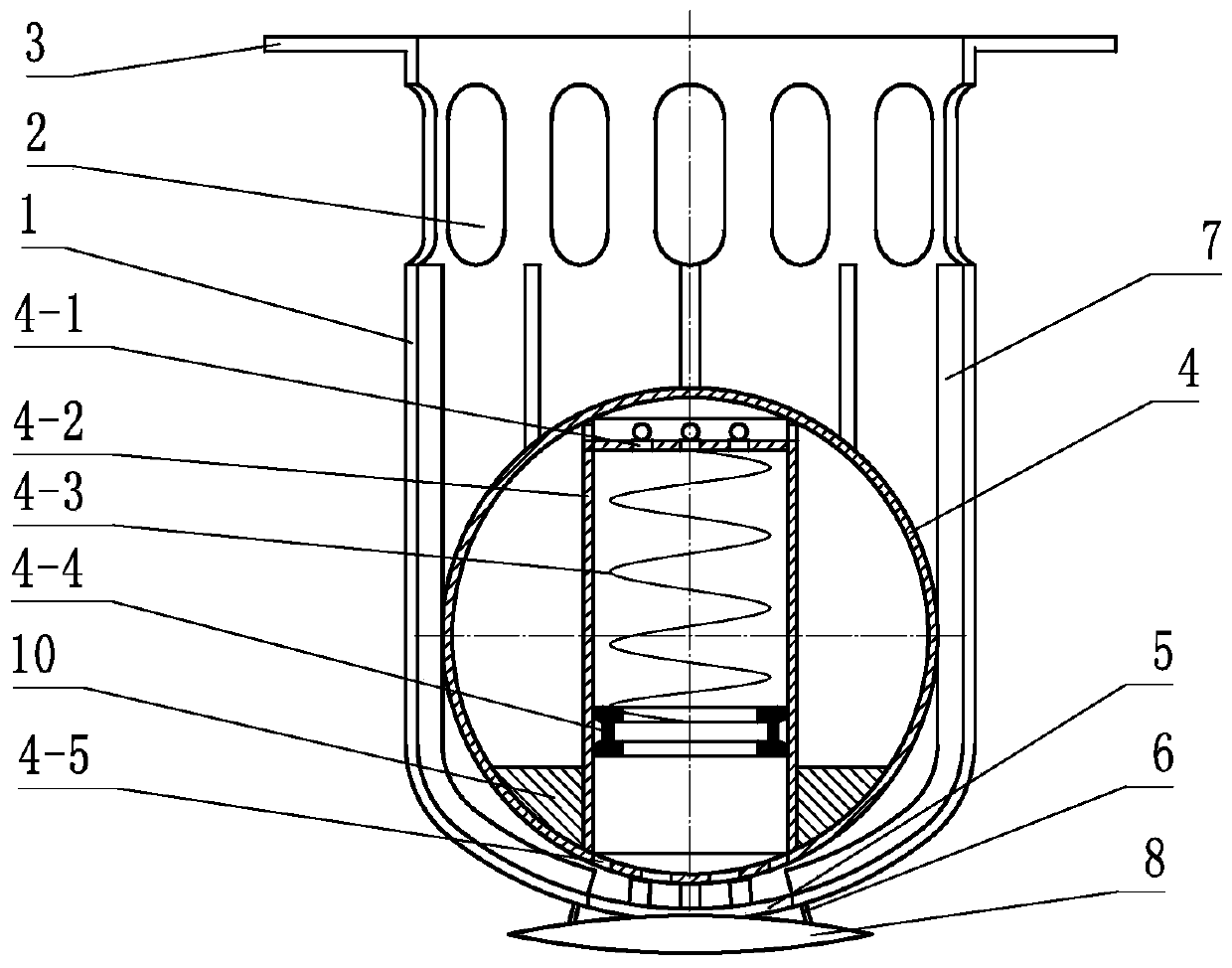

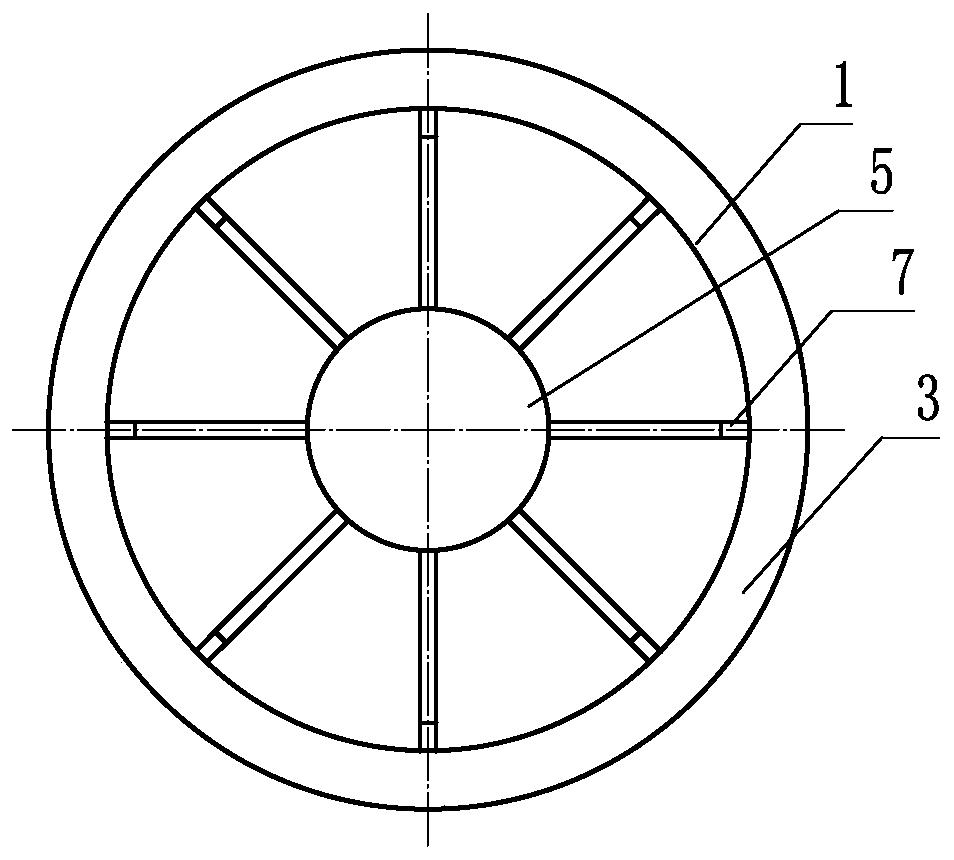

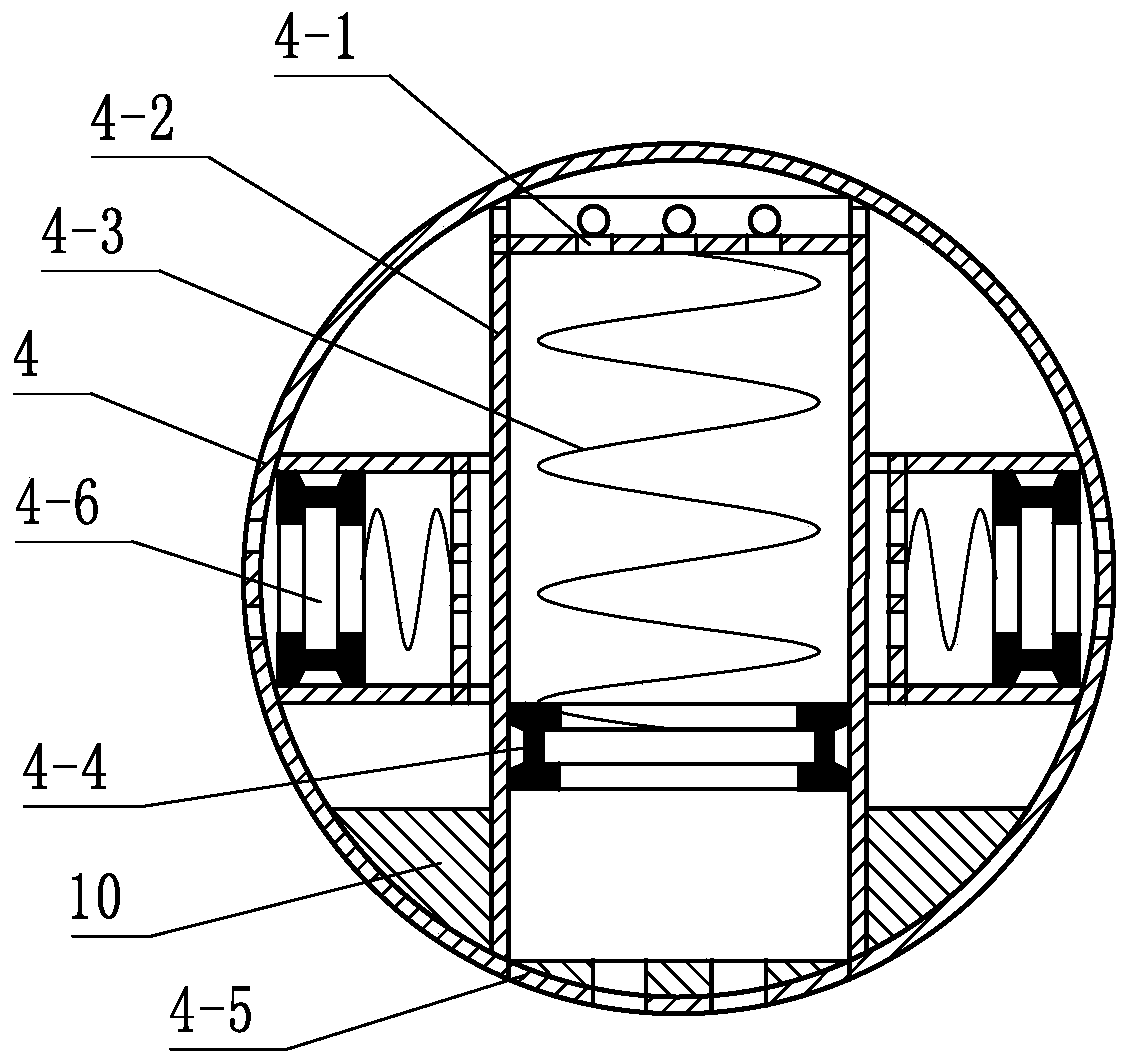

Dynamic precision adjusting device for electric spindle of high-speed machine tool

PendingCN113210641AAvoid dry frictionAvoid Surface Quality IssuesLarge fixed membersValve floatMachine tool

The invention provides a dynamic precision adjusting device for an electric spindle of a high-speed machine tool. The dynamic precision adjusting device comprises a system sealing device, a hydraulic pre-tightening device, a bearing outer ring rotating device and a shaft system rotation error reducing device. The system sealing device is composed of a plurality of O-shaped sealing rings and lip-shaped sealing rings and used for hydraulic sealing among all components. The hydraulic pre-tightening device is used for bearing pre-tightening and mainly comprises wedge-shaped sealing cavities formed among all components, and a second movable valve floats on the surface of hydraulic oil through the pressure of the hydraulic oil. In addition, according to the hydraulic pre-tightening device, hydraulic oil is introduced into the wedge-shaped sealing cavities opposite in position, the second movable valve is subjected to counter-acting force, so that oil pressure fluctuation is eliminated, and meanwhile a filtering device also reduces the oil pressure fluctuation to a certain degree. The bearing outer ring rotating device is used for adjusting the relative positions of bearing outer rings to prevent the wave crests or wave troughs of the raceway harmonic waves of the bearing outer rings from being in the same axis direction, so that the overall runout of bearing set inner rings is reduced. The shaft system rotation error reducing device is used for reducing the run-out error when the shaft end is stressed.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

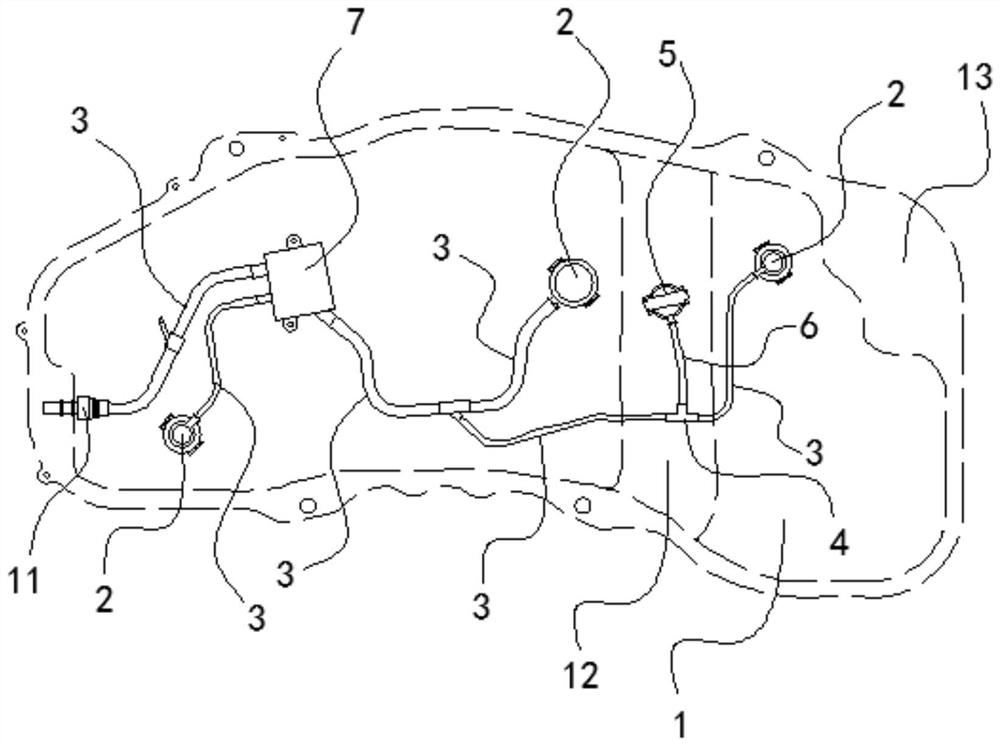

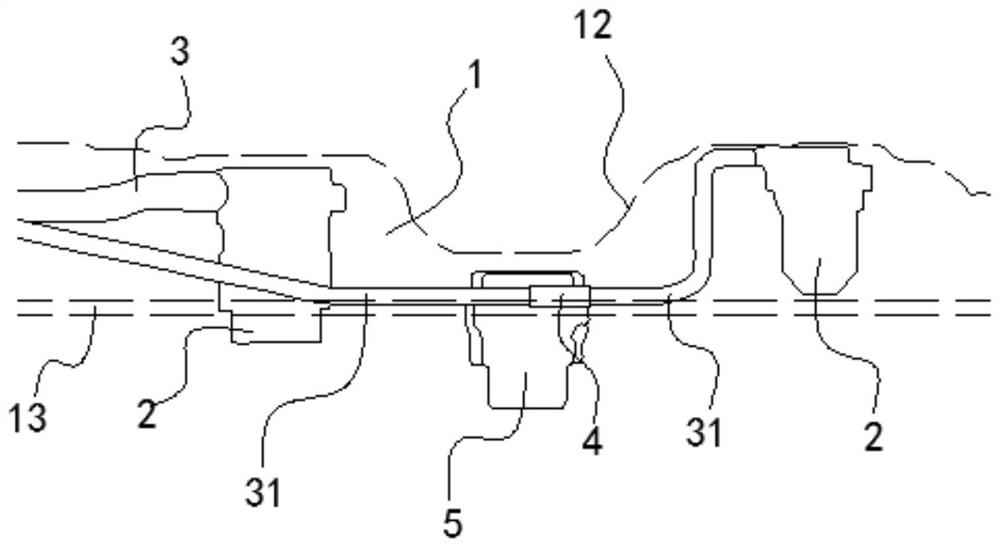

Pressure cooker

PendingCN112167970ASolve the problem that the process strength cannot reach the strength of normal people and cause a force of more than 400N when openingSolve the danger of exploding potPressure-cookersEngineeringValve float

A pressure cooker comprises a surface cover and an upper cover which are assembled into a cooker cover, an assembly gap between the surface cover and the upper cover forms an installation space, the upper cover is provided with an exhaust port, a float valve matched with the pressure cooker is arranged in the exhaust port, a float valve pressure limiting rod and a guide check block triggering thefloat valve pressure limiting rod to move are arranged in the installation space, the guide check block and the float valve pressure limiting rod are movably arranged in the installation space, one end of the float valve pressure limiting rod is located on one side of the exhaust port, the surface cover or the upper cover is provided with a key, and the key is connected with the guide check blockin a matched mode. The key is pressed to drive the guide stop block to move upwards, the guide stop block drives the float valve pressure limiting rod to move towards the exhaust port, and the float valve pressure limiting rod partially shields the exhaust port so as to limit the float valve from floating towards the exhaust port; the pressure in the pressure cooker is large, the float valve floats upwards towards the exhaust port, the float valve pressure limiting rod is prevented from moving towards the exhaust port, the key cannot be pressed, the problem that the cover cannot be opened at will when air pressure exists in the cooker is solved, and the pressure cooker has the advantages of being safe and reliable.

Owner:GUANGDONG GALANZ GRP CO LTD +1

Automobile fuel tank valve body arrangement method and structure

PendingCN114228479AAvoid stress imbalancesLarge containersUnderstructuresMarine engineeringFuel tank

The invention relates to an automobile fuel tank valve body arrangement method and structure. The valve body arrangement structure comprises a fuel tank upper shell, a safety valve, an evaporation pipe, an oil discharge valve and an oil discharge pipe. The oil tank upper shell is provided with an air vent, the safety valve is installed on the inner wall of the oil tank upper shell, and the evaporation pipe is communicated with the air vent and the safety valve. A sinking groove is further formed in the oil tank upper shell, and the evaporation pipe passes through the sinking groove to form a sinking section; the oil discharge valve is mounted on the inner wall of the oil tank upper shell; the oil discharge pipe is communicated with the oil discharge valve and the sinking section; the oil drain valve is arranged to communicate with the sinking section of the evaporation pipe, when the liquid level in the fuel tank descends to a certain height, fuel accumulated in the sinking section flows back into the fuel tank through the oil drain valve, and the situation that the pressure inside and outside the right half part of the fuel tank is unbalanced due to pipeline blockage of the sinking section is avoided; 2, the oil discharge valve is preferably a GVV valve, and when the oil tank is full of the oil level, an inner valve body of the GVV valve floats upwards under buoyancy and is automatically closed; and when the fuel level drops to a certain height, the floater in the GVV valve sinks and is automatically opened.

Owner:VOYAH AUTOMOBILE TECH CO LTD

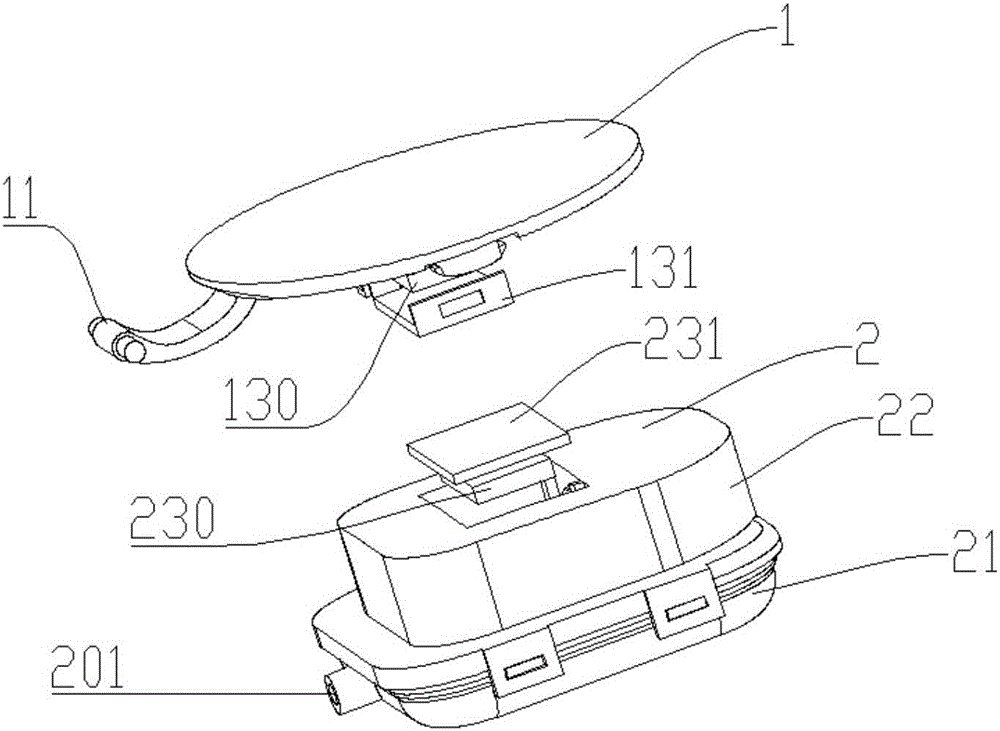

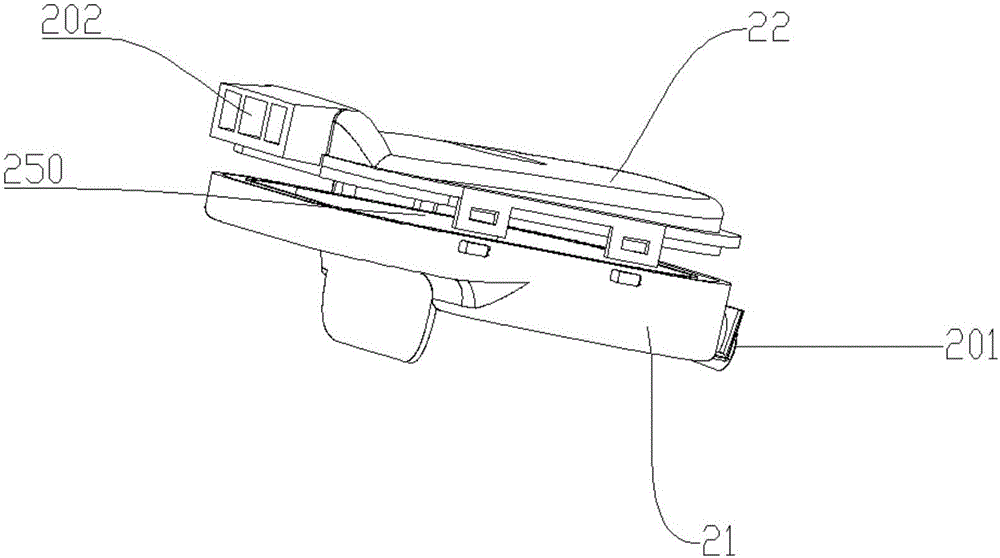

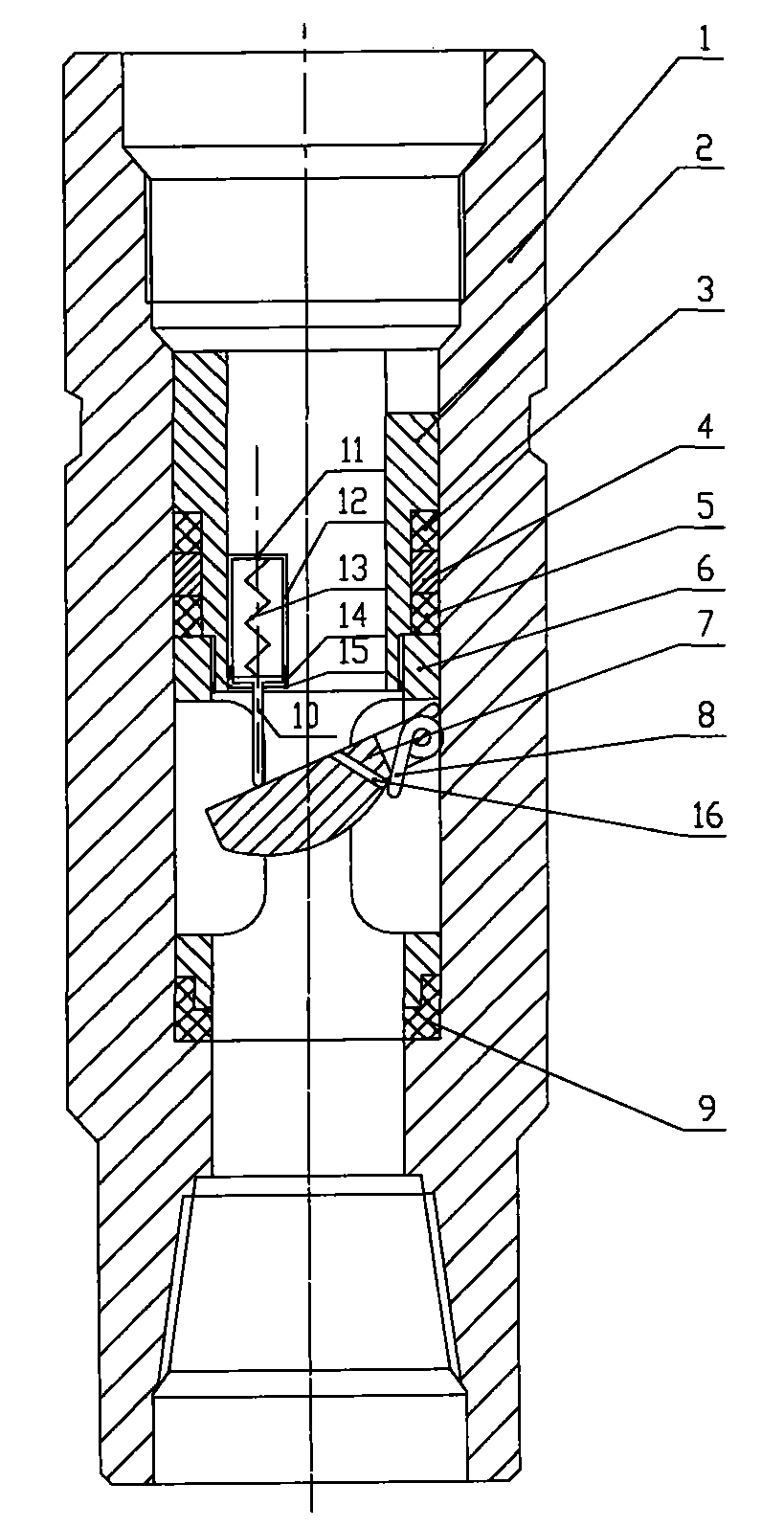

Suction and exhaust valve floating ball and suction and exhaust valve composed of floating ball

PendingCN110701368ASafe and smoothOperating means/releasing devices for valvesLift valveExhaust valveSystem pressure

The invention discloses a suction and exhaust valve floating ball capable of being adjusted according to system pressure and a suction and exhaust valve composed of the floating ball. The suction andexhaust valve floating ball comprises a floating ball shell (4), an adjusting mechanism used for adapting to the outside pressure is arranged in the floating ball shell (4), and the adjusting mechanism is a piston-shaped mechanism or a balloon-shaped mechanism in an inner cavity of the floating ball shell (4). Compared with the prior art, the suction and exhaust valve floating ball can be adjustedaccording to the system pressure, adapts to change of the pressure in a conveying pipeline to a certain extent, and it is ensured that the conveying pipeline is safe and smooth.

Owner:奎屯耐特阀门科技有限公司

Speed-dependent linear self-supercharging air supply device for motor vehicle internal combustion engine

ActiveCN107917021BImprove linearityBurn completelyMachines/enginesAir intakes for fuelStraight tubeValve float

The invention provides a motor vehicle internal combustion engine speed-sensitive linear automatic supercharging air supply device. The air supply device is provided with a supercharging chamber communicating with an air inlet pipe of an internal combustion engine. An air inlet of the supercharging chamber faces against the wind generated by a motor vehicle during advancing, and the air pressure in the supercharging chamber and the air supply amount of the internal combustion engine are automatically increased and reduced along with change of the vehicle speed. The supercharging chamber can beof a combined structure, or an eggshell type structure, a whistle type structure, or a horn type structure or a straight pipe type structure. The combined supercharging chamber is composed of a supercharging chamber body and an auxiliary supercharging chamber body on the upper portion. A valve grid is arranged between the supercharging chamber body and the auxiliary supercharging chamber body. Anair pressure valve is arranged on the valve grid and is limited between guide rods to float up and down. The upper end of the auxiliary supercharging chamber body is provided with an auxiliary air inlet used for being sealed when the air pressure valve floats up. An internal combustion engine air inlet pipe communicates with the auxiliary supercharging chamber body. A pipe serves as the air inletand goes into the supercharging chamber body in the tangential direction. Air is fed into the internal combustion engine through the wind pressure generated by the motor vehicle during running to increase the air supply amount and promote sufficient burning of fuel oil. The power of the internal combustion engine is increased. Oil consumption is reduced. Carbon deposit of the internal combustionengine is reduced. The purchase cost and the maintenance cost of the motor vehicle are reduced.

Owner:HONGHE COLLEGE

Double spring support pull type automatic filling valve float valve

The invention discloses a double spring support pull type automatic filling valve float valve. The automatic filling valve float valve is characterized in that a float valve is arranged in a float valve joint, a valve is hinged to a valve seat of the float valve, the elastic force of a torsion spring which is supported on the valve and the valve seat can enable the valve to be closed up with the valve seat when the valve is in a free state, the principle that the holding force and pulling force of a tension spring are used for balancing the elastic force of the torsion spring when an automatic closing valve type float valve is closed, and the force which flows into a pipe and is caused by liquid column pressure difference inside and outside the pipe can make the valve be always in an ajar state, a fluid flow passage is formed, and the purpose of automatic filling is achieved. When kick or blowout happens in the pipe, the tension spring of the valve is lengthened under the action of flowing liquid in the pipe. The valve is closed, and plays the action of a single flow valve. The problem of being unable to automatically fill of the existing valve type float valve is solved. The tension spring and the torsion spring are replaced and the force and the length of the springs are adjusted before the drilling tool is run into a well every time; the double actions of the double springs avoid the abuse of losing effectiveness of the float valve after the torsion spring is easily broken.

Owner:慕武

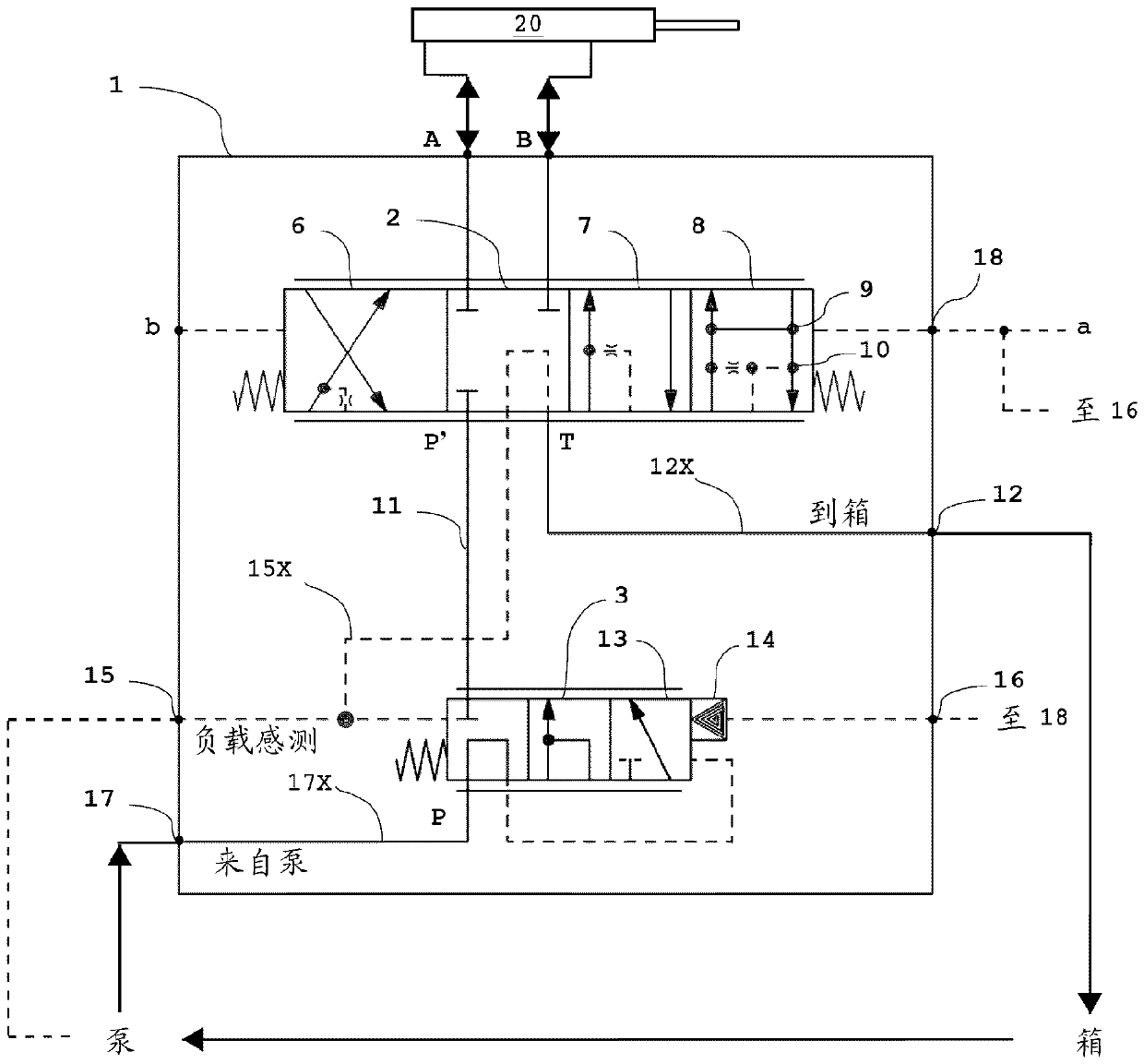

Hydraulic control valve

PendingCN110836209AImprove efficiencyIncrease powerServomotor componentsPump assembliesEngineeringValve float

The invention relates to a hydraulic control valve. A new means of achieving a valve float position in a closed centered hydraulic control valve. The valve has a main spool position whereby pressure compensator load sense control pressure is drained to tank through the main spool. Secondly, a pin acts on the pressure compensator to prevent the main pump flow from reaching the main section spool. Finally, the new spool position adds a connection from the consumer to tank, enabling a float position.

Owner:ROBERT BOSCH GMBH

Fuel vapor vent valve float assembly and method of making same

InactiveCN1721751APrevent removalPrevent overflowOperating means/releasing devices for valvesAeration devicesCircular discExhaust valve

A float assembly for a multifunction fuel vapor vent valve with a float having a recess formed in the upper surface of the float with a slot formed in the side of the float and communicating with the recess. A raised surface portion is formed in the bottom of the recess and downwardly extending projections are formed in the slot at the recess. A flexible wafer like valve disk is inserted in the slot and deformed or curled to pass under the projections and over the raised surface and into the recess. When fully received in the recess the disk returns to its flat configuration; and, the downward projections prevent removal without distortion. Radially inwardly projections about the recess retain the disk for limited lost motion in the direction of float movement.

Owner:EATON INTELLIGENT POWER LTD

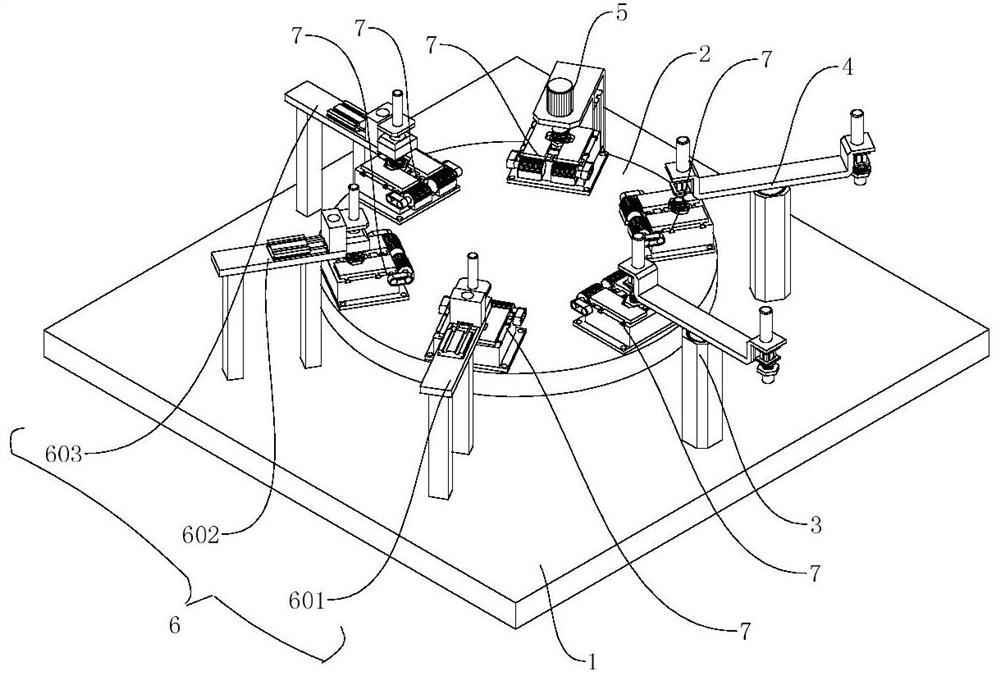

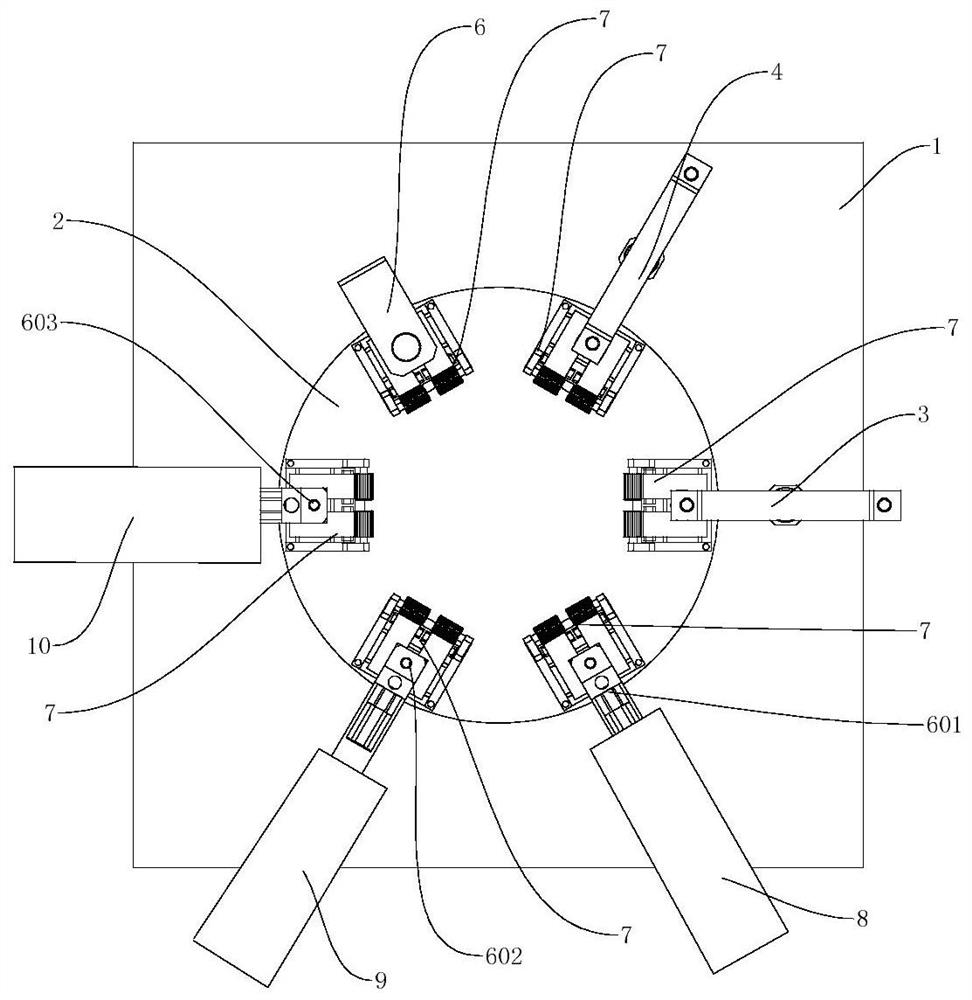

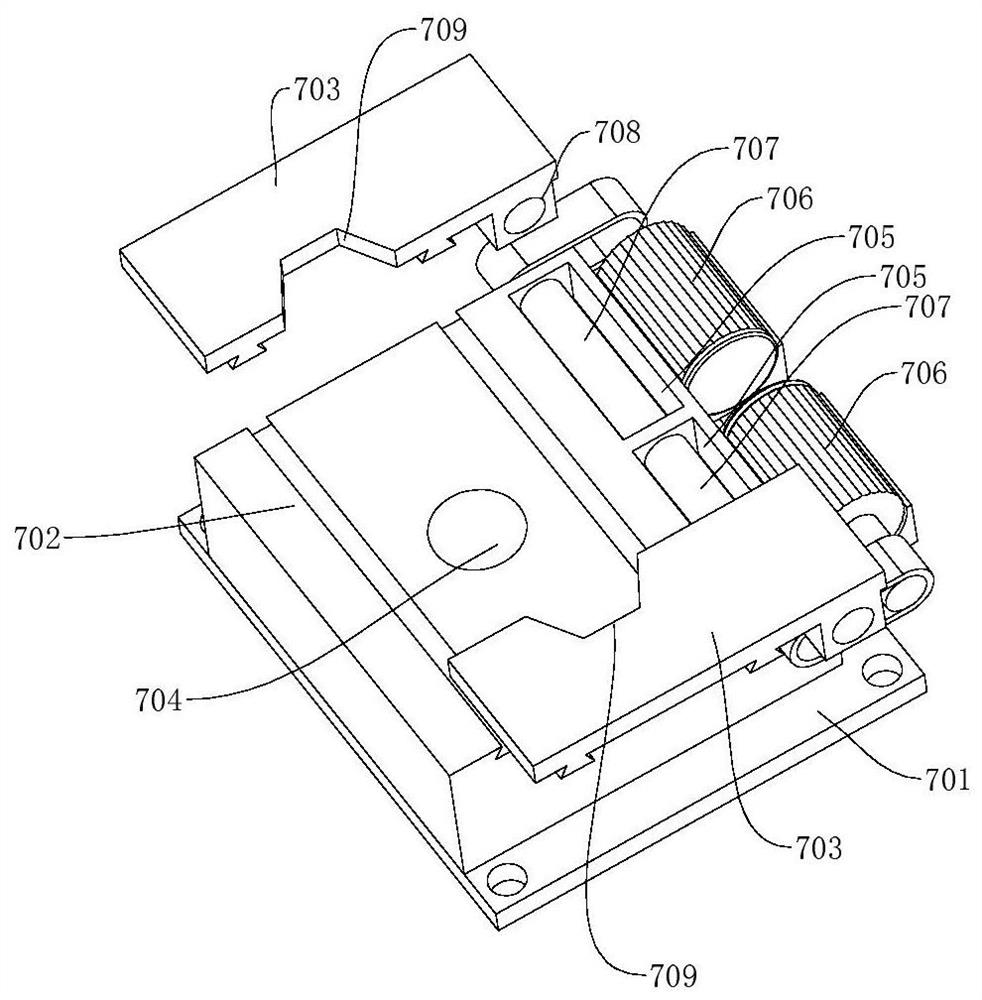

A water purifier float valve float joint automatic assembly equipment

ActiveCN110315338BImprove machining accuracyHigh degree of automationAssembly machinesMetal working apparatusContinuous/uninterruptedAssembly line

The invention relates to the technical field of automatic processing, in particular to an automatic assembly equipment for floating ball joints of water purifier float valves, which includes a workbench, a turntable, a feeding assembly, a feeding assembly, a feeding device and a processing assembly, and the turntable is horizontally arranged on Above the workbench, the lower end of the turntable is provided with a servo motor, and the feeding assembly, the first feeding mechanism, the second feeding mechanism, the third feeding mechanism, the processing assembly and the unloading assembly are respectively connected to each tooling assembly. The indirect rotation of the turntable and a series of feeding components, unloading components, feeding devices and processing components arranged around the outer circumference of the turntable enable the production and processing of the joints to be processed continuously and uninterruptedly in an assembly line. The degree of automation High, no manual operation is required, which can greatly save labor costs, and can greatly improve the processing accuracy of the connector, thereby greatly improving the pass rate and reducing production costs.

Owner:诸暨市港灵科技有限公司

A high and low water level adjustment rotary pilot valve float valve

ActiveCN103982699BAvoid frequent openingExtended service lifeOperating means/releasing devices for valvesAutomatic controlValve float

The invention provides a high and low water level adjusting rotary guide valve floating ball valve. The floating ball valve comprises a floating ball, a support rod, a bracket, a four-way reversing valve and a floating ball main valve, wherein the support rod passes through a center shaft of the floating ball; the floating ball can slide upwards and downwards along the support rod; the upper segment of the support rod is connected with one end of an upper pull rod and one end of a lower pull rod through hinge pins; the other end of the upper pull rod is connected with a balance block; the middle segment of the upper pull rod can rotate about a fixed shaft on the bracket; the other end of the lower pull rod is connected with a valve of the four-way reversing valve; three holes are formed in the four-way reversing valve, and are connected with the lower control cavity, the water inlet and the upper control cavity of the floating ball main valve in sequence; the fourth hole is an emptying hole. The high and low water level adjusting rotary guide valve floating ball valve has the beneficial effects that the frequent starting of the floating valve main valve is avoided, and the service life of the floating ball main valve is prolonged; when the inlet water pressure is excessively low, the opening and closing of the floating valve main valve can be controlled normally, and automatic control is realized.

Owner:TIANJIN GUOWEI FEEDING & DRAINAGE EQUIP MENT MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com