Pin-pulled broken-type automatic grouting valve floating valve

An automatic grouting and pinning technology, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of delaying time, increasing labor intensity of workers, and delaying the progress of oil and gas exploration, so as to speed up the decentralization and save Drilling cycle and the effect of avoiding stuck pipe accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

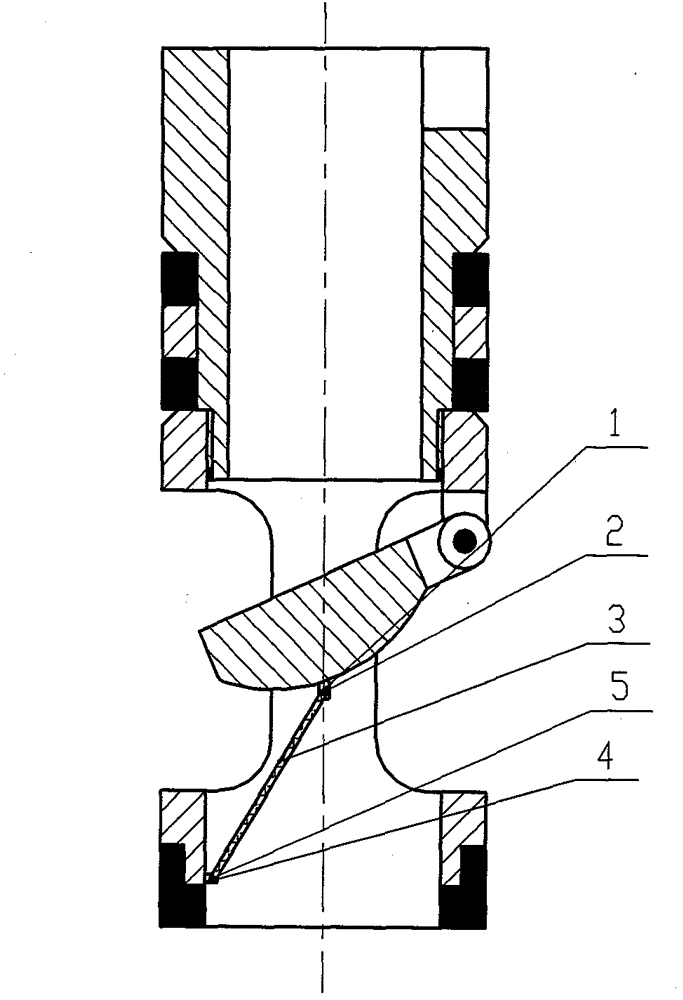

[0013] Such as figure 1 As shown, a pin pull-off type automatic grouting valve float valve is mainly composed of valve cover pin hinge seat 1, pin 2, support rod 3, valve body pin hinge seat 4, and pin 5 on the basis of the valve type float valve. .

[0014] One of support rod 3 is connected with valve cover pin hinge seat 1 with pin 2, and the other end is connected with valve body pin hinge seat 4 with pin 5. The valve is in a half-open state to form a fluid channel to achieve the purpose of automatic grouting. When the pump is turned on and circulated, the support rod 3 is pulled and broken, and the valve is automatically closed under the action of the spring to play the role of a check valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com