Motor vehicle internal combustion engine speed-sensitive linear automatic supercharging air supply device

An air supply device and internal combustion engine technology, applied in the direction of machines/engines, fuel air intake, combustion air/combustion-air treatment, etc., can solve the problem of small diameter, increased vehicle cost and maintenance costs, and unsmooth air supply, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The implementation process and beneficial technical effects of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by these examples.

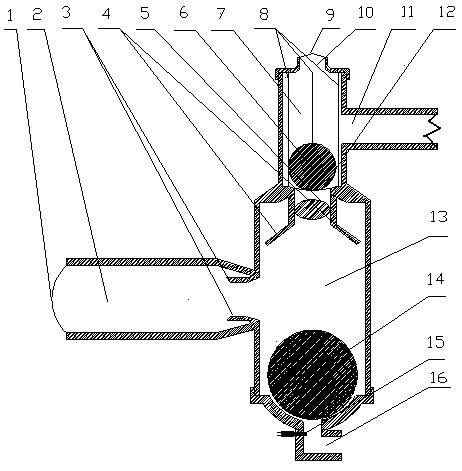

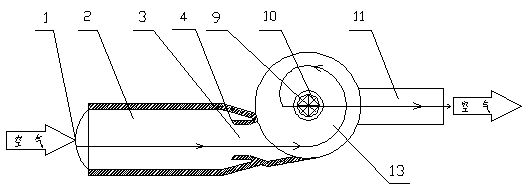

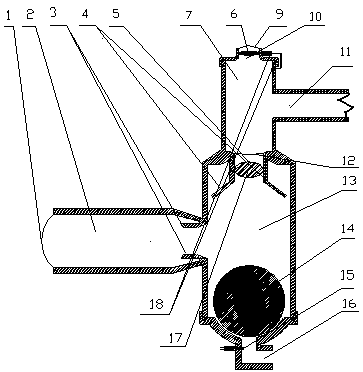

[0042] Take the speed-dependent linear self-increasing air supply device of a motor vehicle internal combustion engine with compound pressurization chamber as an example. Such as Figure 1-5As shown, the booster chamber 13 is a cylinder made of metal material or plastic, and the air inlet 2 is a tube of the same material with a slightly thinner diameter, which is connected to the booster chamber in a tangential direction so that the air enters in a spiral manner. rise. The bottom of the pressurization chamber is spherical and has a sewage outlet 16 in the center to facilitate the discharge of water droplets, dust particles and other dirt agglomerated in the pressurization chamber. A rubber cortex hollow plugging ball 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com