Pressure-transmitting supporting automatic grouting valve float valve

An automatic grouting and top-supporting technology, which is applied to wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as automatic grouting, avoid blowout in pipes, and avoid stuck pipe accidents , Reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

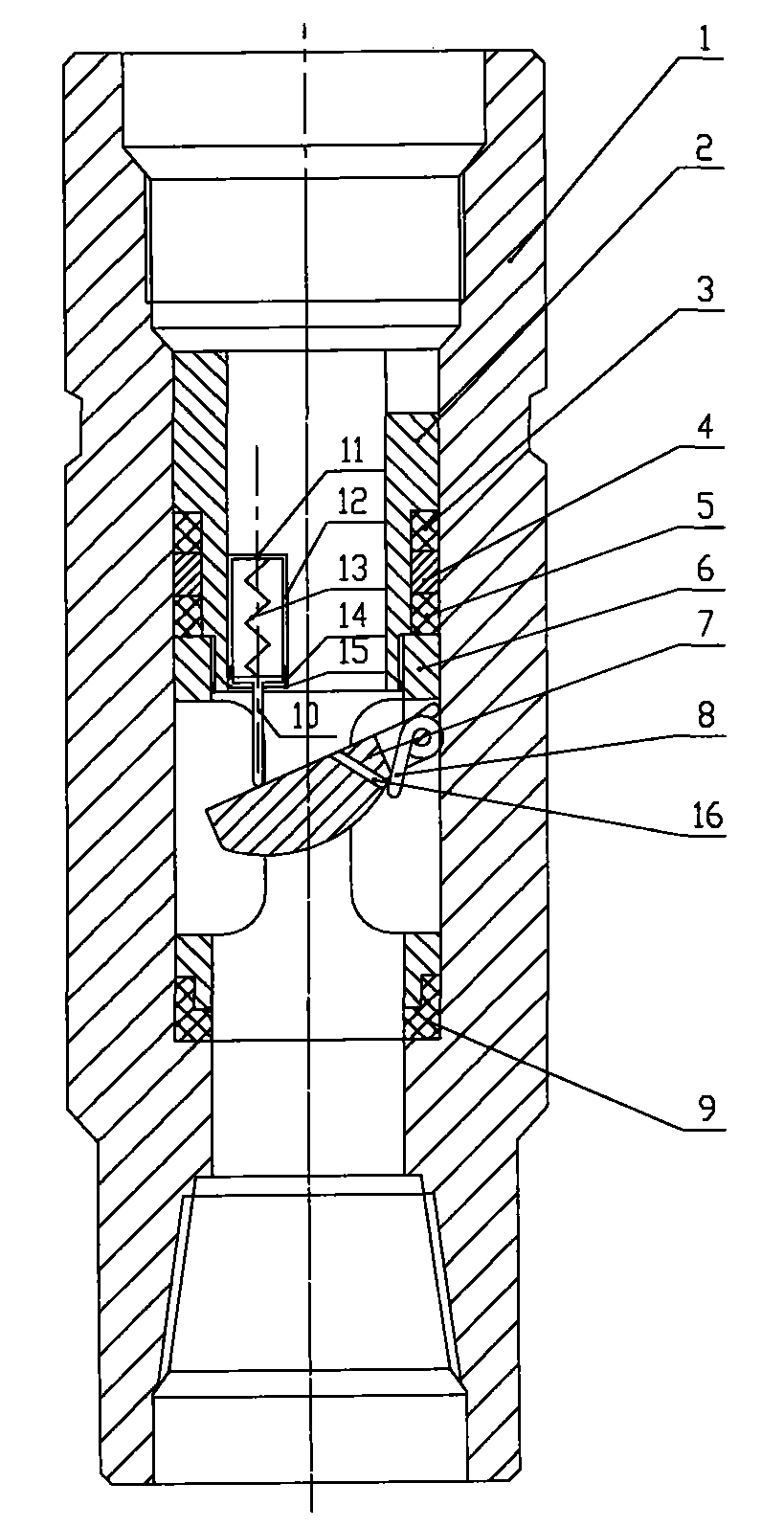

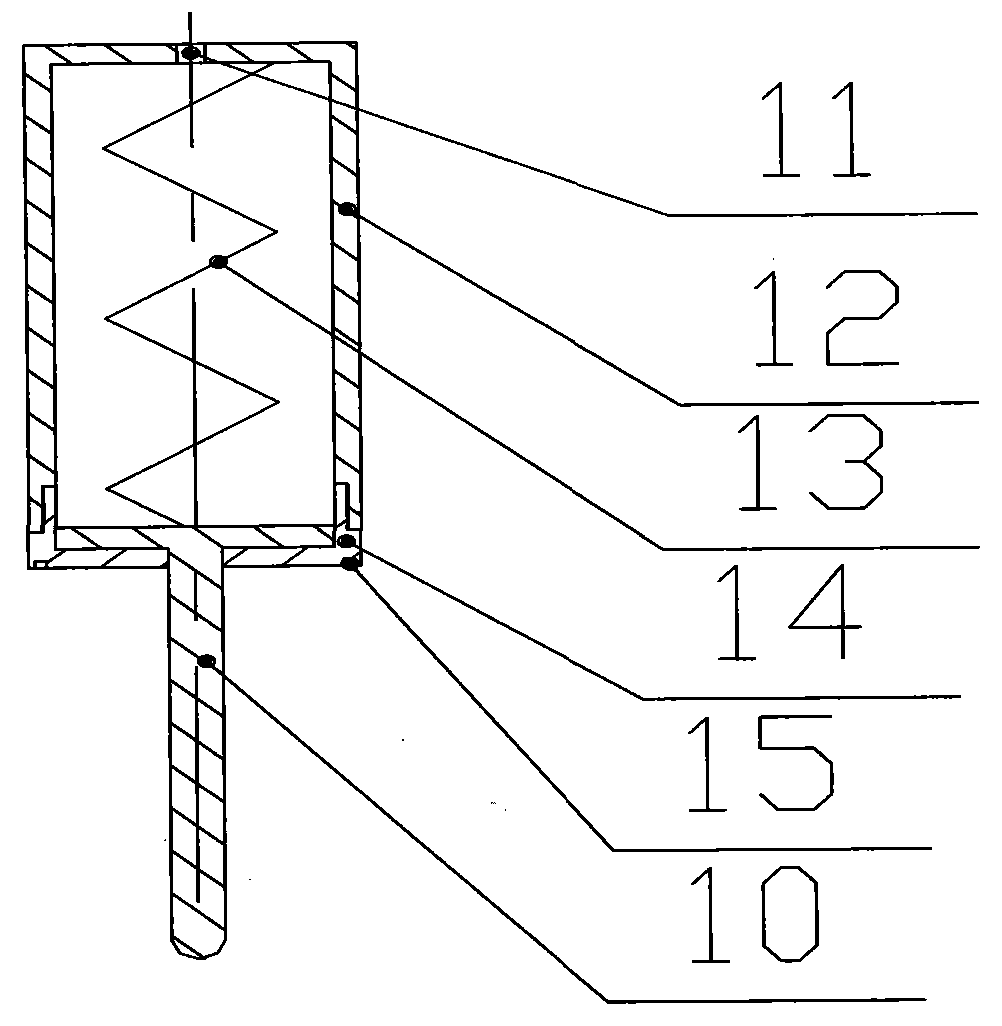

[0014] Such as figure 1 As shown, an automatic grouting valve float valve that can be supported by pressure transmission is composed of a float valve joint 1, a float valve and a valve support device. Float valve is made of upper valve body 2, upper sealing ring 3, gasket ring 4, middle sealing ring 5, valve body seat 6, valve 7, torsion spring 8, lower sealing ring 9, pressure transmission aperture 16. The upper valve body 2 is connected with the valve body seat 6 with threads, the upper sealing ring 3, the gasket ring 4 and the middle sealing ring 5 are set on the upper valve body 2, and the inner diameter of the float valve is basically the same as that of the float valve joint 1 There is an inner convex shoulder surface on the inner wall of the float valve joint 1, the float valve is placed in the float valve joint 1, and the lower end of the lower sealing ring 9 sleeved on the lower end of the valve body seat 6 pushes against the inner convex shoulder surface to form a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com