High Tension Valve Spring and Valve Float Eliminator

a valve spring and high-pressure technology, applied in the direction of valve details, non-mechanical valves, valve arrangements, etc., can solve the problems of poor power transmission, catastrophic failure, and poor fuel consumption ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

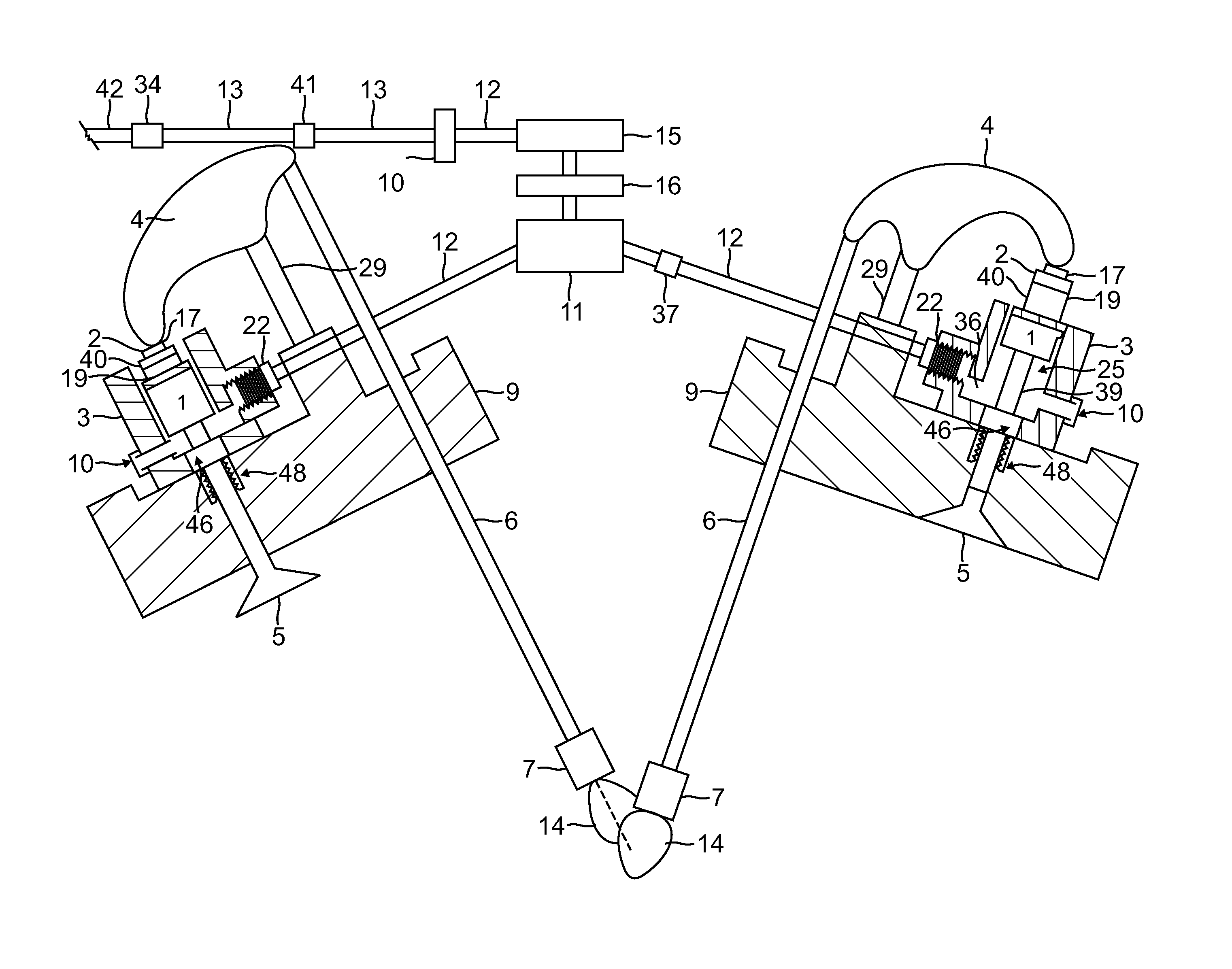

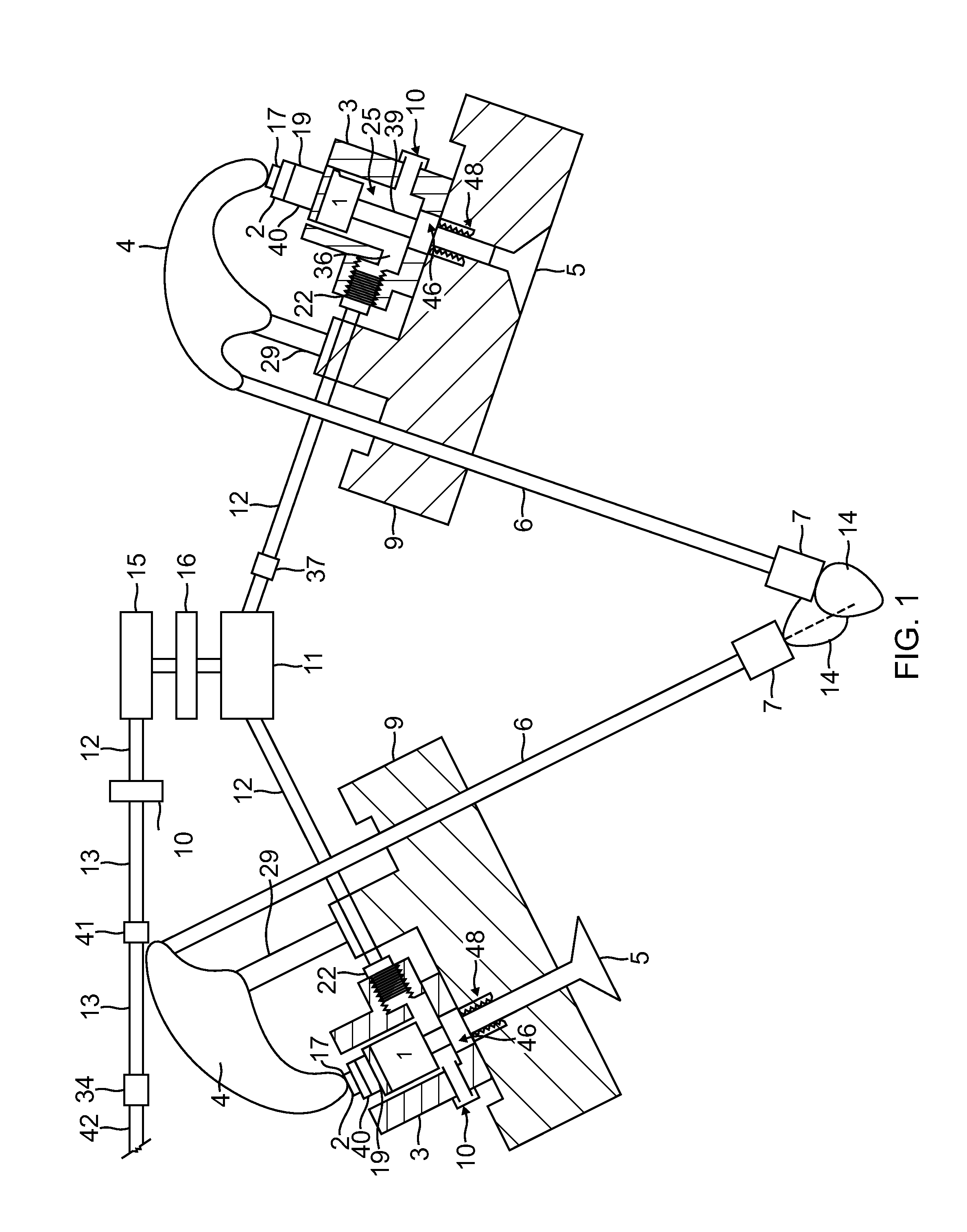

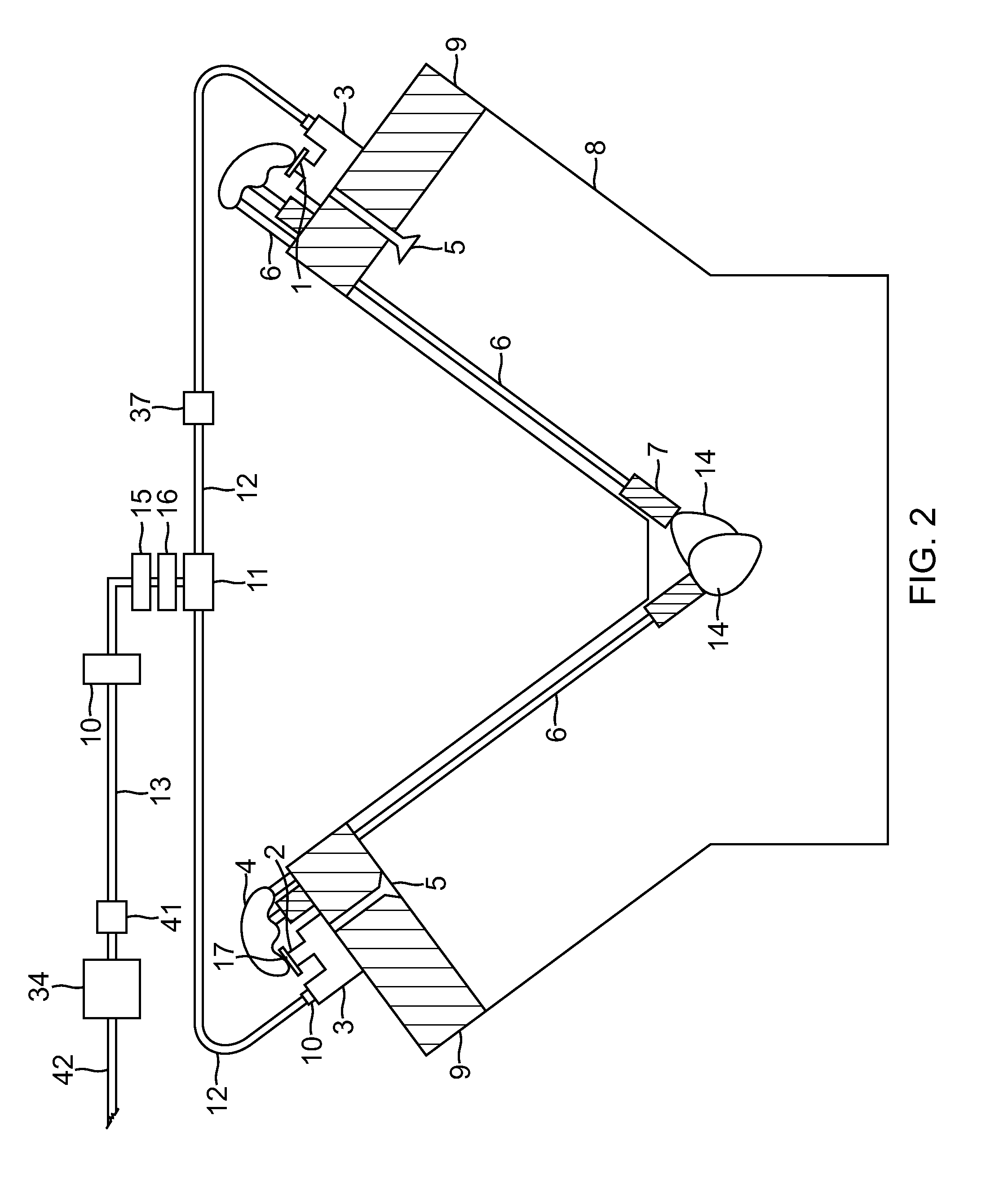

[0088]Most multiple cylinder engines have for every cylinder an exact opposite cylinder firing in perfect synchronization. This invention utilizes this opposite firing principle, when a cylinder is ready to fire and the valves are closed and ready for combustion, the exact opposite is occurring in a different cylinder. We can use this phenomena to cause action in its opposite firing cylinder with perfect synchronization of movement. This invention is a standalone valve actuation system with backup components which can be used for practically any multiple cylinder engine. There is no pump needed as each opposite cylinders existing rocker arm powers the actuator cylinder which power each other. This invention utilizes the engines original camshaft, lifters rocker arms and pushrods and is installed on top of the engine and requires little or no machining to retrofit the existing engine.

[0089]The present invention takes an enormous amount of stress from the engines valve train as one ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com