Experimental device for axial compression experiments of plates

An experimental device, the technology of axial compression test, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, analyzing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the embodiments of the present invention are not limited thereto. At the same time, it should also be understood that the terminology used herein is only used to describe specific implementations, and is not used to limit the scope of protection claimed in the present application.

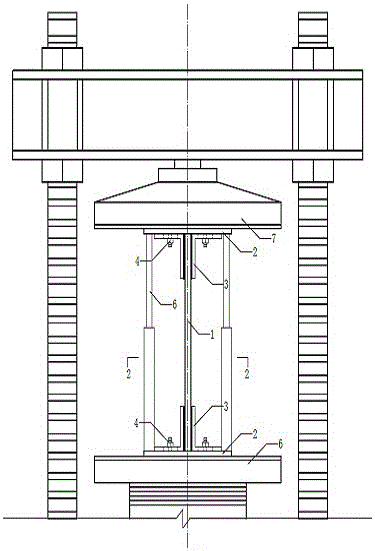

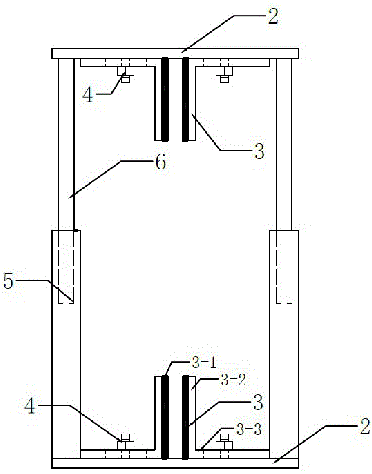

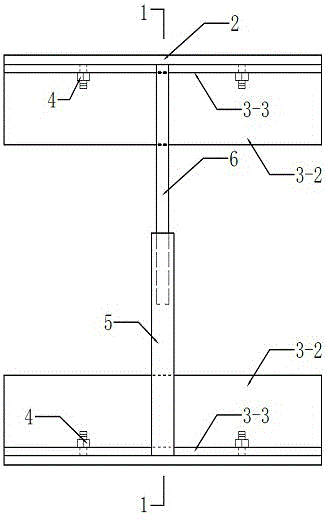

[0030] Such as figure 1 As shown, the working environment of the present invention is the two ends of the axial compression plate specimen. As shown in the figure, the plate specimen (1) and the end plate (2), the clamping device (3), the locking device (4), the lower support rod (5), the upper support rod (6) and the working platform of the press (7). The centroid of the compression surface section of the plate test piece, the end face center of the end plate and the center of the press working face coincide; the displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com