Inter-cooling pipe fixing device

A fixing device and cold pipe technology, which is applied in the layout, transportation and packaging of the power plant and the cooling combination of the power plant, can solve the problems of fatigue fracture of the bracket, improper installation, displacement of the engine installation position, etc., to improve the rigidity and Strength, easy disassembly and maintenance, firm and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

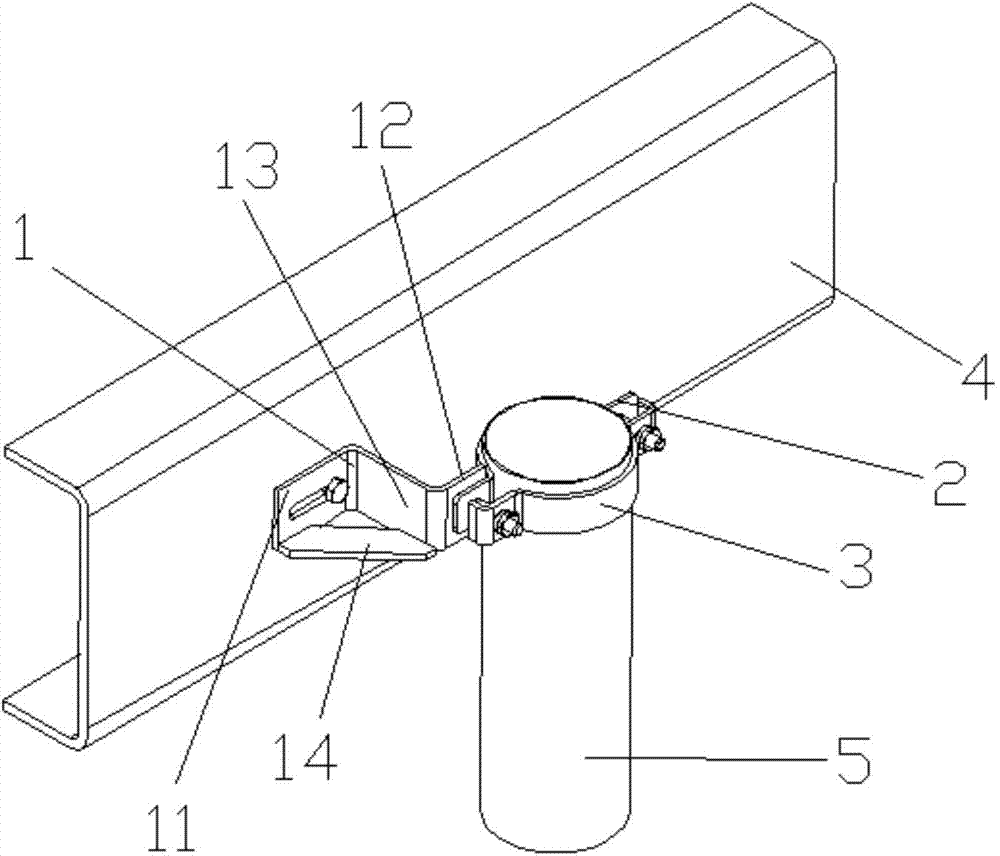

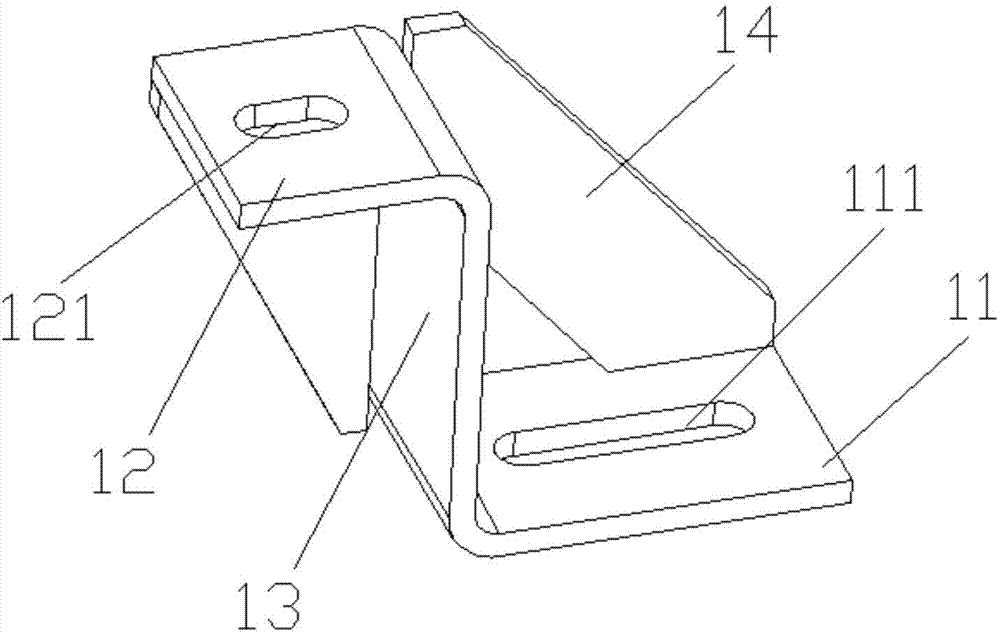

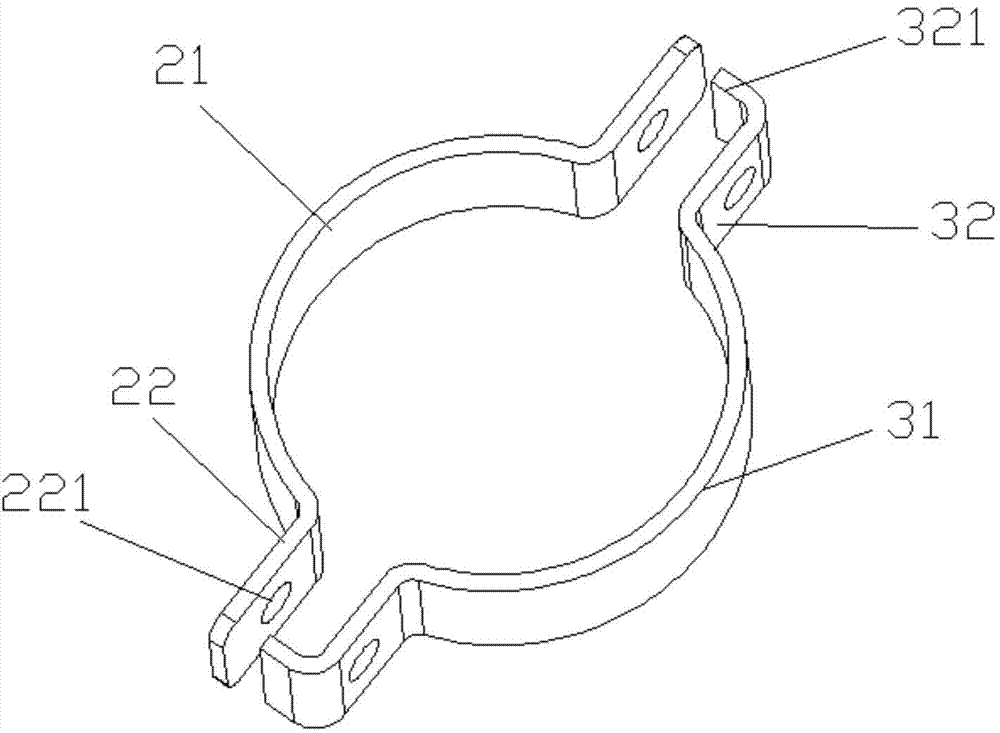

[0021] refer to Figure 1 to Figure 3 As shown, the intercooler pipe fixing device of the present invention is applied to fix the engine intercooler pipe of a passenger car, including: a Z-shaped connecting bracket 1, a first semicircular hoop 2 and a second semicircular hoop 3; the Z The type connection bracket 1 includes: a first installation surface 11 that is connected with the vehicle frame 4, a second installation surface 12 that is connected with the first semicircular hoop 2, and a connection surface 13 that connects the above two installation surfaces. The first mounting surface 11 is provided with a first elongated hole 111, and the first elongated hole 111 is provided with a bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com