Track type multilayer moving silkworm stand

A track-type, silkworm frame technology, applied in the field of silkworm breeding, can solve the problems of laborious, cumbersome operation, high operating space, etc., achieve the effect of convenient sand removal, reduce labor intensity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

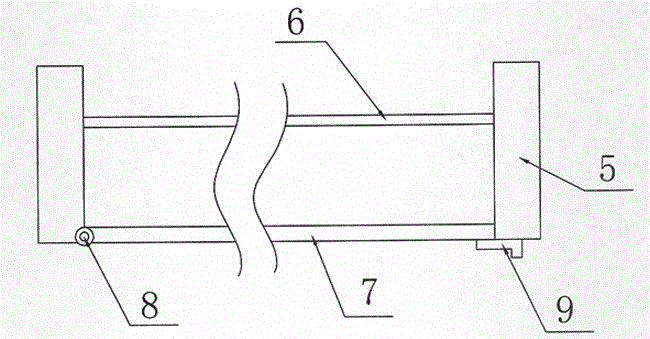

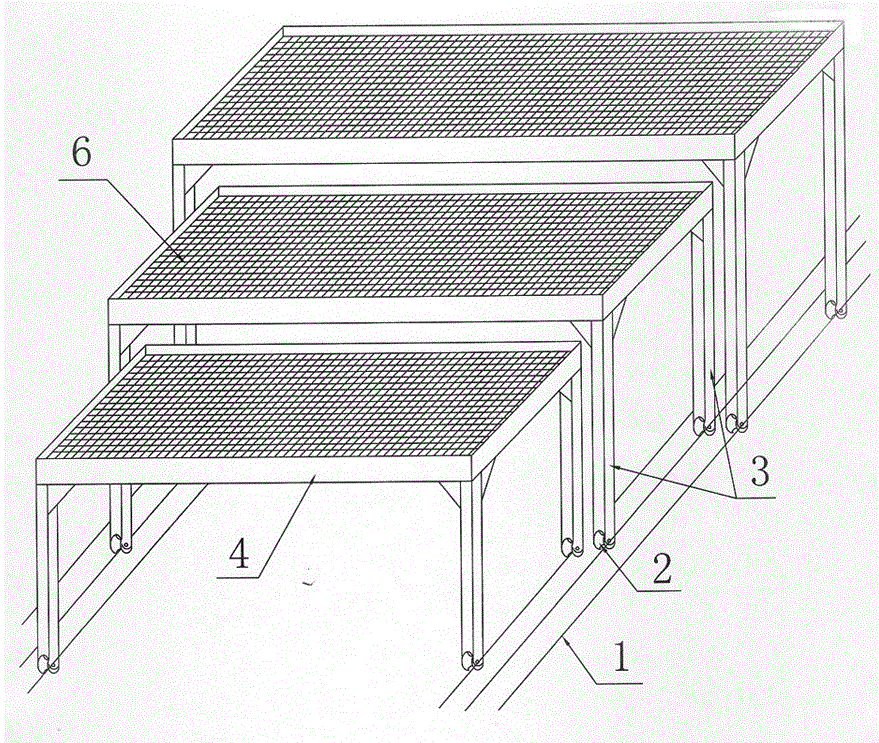

[0014] Embodiment 1: as attached figure 1 , 2 As shown, a track-type multi-layer mobile silkworm frame includes a track 1, a pulley 2, a column 3 and three silkworm platforms 4, and the three silkworm platforms 4 can be nested on the same facade in turn, and each silkworm platform Platform 4 is all supported by four columns 3, and each silkworm platform 4 includes a silkworm platform frame 5, a silkworm seat mesh 6 and a silkworm sand tray, and one end of the bottom plate 7 of the silkworm sand tray is fixed to the silkworm platform frame 5 by a hinge 8, The other end is movably connected with the frame 5 of the silkworm platform through the movable pin 9 to realize the opening and closing of the bottom plate 7 of the silkworm sand tray to facilitate sand removal; the mesh size of the silkworm seat mesh is 10*10mm. The bottom of each column 3 is provided with a pulley 2, and the track 1 is matched with the pulley 2 to realize the movement of each silkworm platform 4.

Embodiment 2

[0015] Embodiment 2: Another track-type multi-layer mobile silkworm frame, including tracks, pulleys, columns and 5 silkworm platforms, each silkworm platform includes a silkworm platform frame, a silkworm seat mesh and a silkworm sand tray, and the silkworm sand tray It is movable connected with the frame of the silkworm platform through slide rails to facilitate sand removal; the mesh size of the silkworm platform mesh is 20*20mm. Others are the same as in Example 1.

Embodiment 3

[0016] Embodiment 3: Another track-type multi-layer mobile silkworm frame, including a track, a pulley, a column and 6 silkworm platforms, each of which includes a silkworm platform frame, a silkworm seat mesh and a silkworm sand tray; the silkworm seat The mesh and the frame of the silkworm platform are detachable structures. Several hooks are arranged in the frame of the silkworm platform. The mesh of the silkworm seat and the hooks realize the random replacement of the size of the silkworm seat mesh, which is suitable for use at any age of silkworms. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com