Antiwear agent used for lubricating oil, and preparation method thereof

An anti-wear agent and lubricating oil technology, applied in the field of lubricating oil, can solve the problems of sludge mixed in the lubricating oil or attached to the cylinder wall and other parts, affecting the normal operation of the engine, and increasing the viscosity of the lubricating oil. Effect of avoiding clogging, improving service life and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

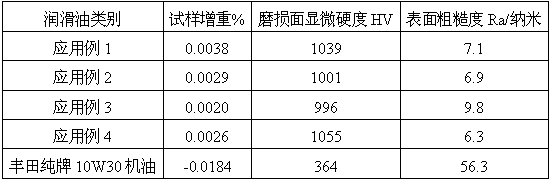

Examples

Embodiment 1

[0026] An antiwear agent for lubricating oil, the antiwear agent for lubricating oil is composed of the following components in parts by mass: lubricating oil base oil: 60, h -BN nanosheets: 5; nanographene: 7; aluminum hydroxide: 3; boron oxide: 2; polyisobutylene succinimide 2; aliphatic amine polyoxyethylene ether 1.5, succinimide: 3,

[0027] The above-mentioned antiwear agent for lubricating oil is prepared according to the following method: mix the raw materials in the sealing device according to the ratio of raw materials, use nitrogen to remove the air in the sealing device after mixing, and then ultrasonically disperse them for 4 hours to obtain a suspension .

Embodiment 2

[0029] An antiwear agent for lubricating oil, the antiwear agent for lubricating oil is composed of the following components in parts by mass: lubricating oil base oil: 50, h -BN nanosheets: 5; nanographene: 5; aluminum hydroxide: 4; boron oxide: 2; polyisobutylene succinimide 1.5; aliphatic amine polyoxyethylene ether 2, succinimide: 3,

[0030] The above-mentioned antiwear agent for lubricating oil is prepared according to the following method: mix the raw materials in the sealing device according to the ratio of raw materials, use nitrogen to remove the air in the sealing device after mixing, and then ultrasonically disperse them for 4 hours to obtain a suspension .

Embodiment 3

[0032] An antiwear agent for lubricating oil, the antiwear agent for lubricating oil is composed of the following components in parts by mass: lubricating oil base oil: 60, h -BN nanosheets: 8; nanographene: 5; aluminum hydroxide: 5; boron oxide: 2; polyisobutylene succinimide 2; aliphatic amine polyoxyethylene ether 2, succinimide: 2,

[0033] The above-mentioned antiwear agent for lubricating oil is prepared according to the following method: mix the raw materials in the sealing device according to the ratio of raw materials, use nitrogen to remove the air in the sealing device after mixing, and then ultrasonically disperse them for 4 hours to obtain a suspension .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com