Rotational molding forming device

A technology of rotating molds and forming molds, applied in the coating and other directions, can solve the problems of poor temperature control accuracy and temperature uniformity, low heat transfer efficiency on the mold surface, and high mold cost, so as to improve the temperature control accuracy, avoid heat loss, and improve product quality. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

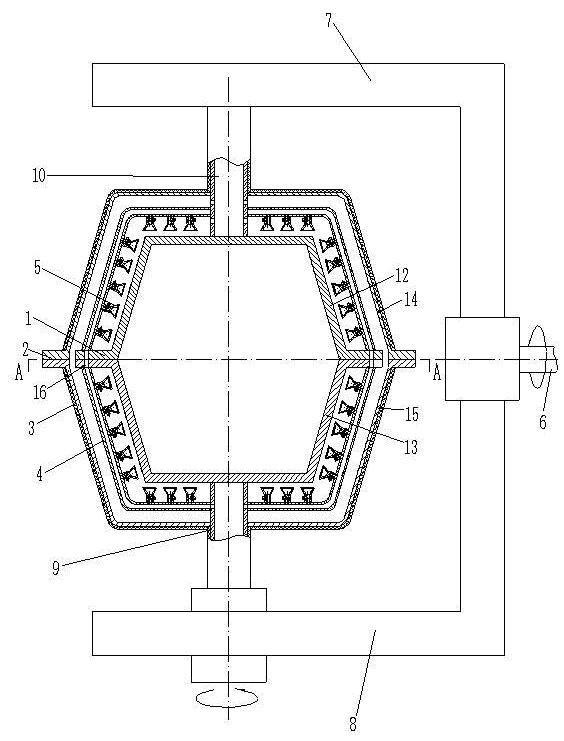

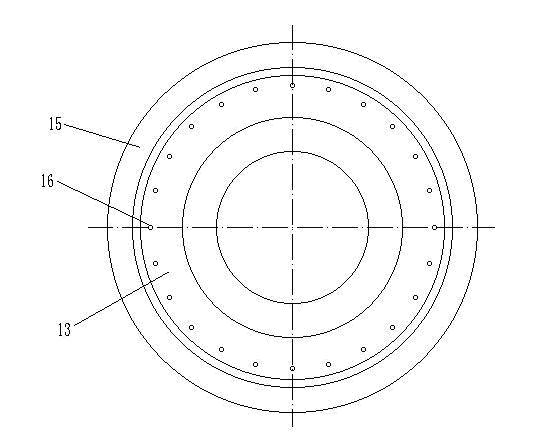

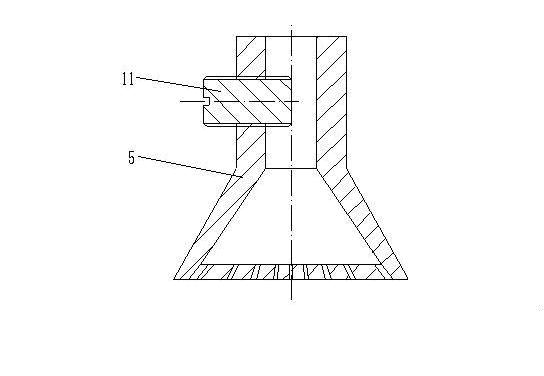

[0015] The present invention provides a rotary molding device, and the molding die adopts air jet heating. Take a two-axis rotary molding equipment as an example. The device mainly includes a temperature control system, a molding die 1, a motion control system. The motion control system is connected to the molding die 1, so that the molding die 1 can obtain the required biaxial rotation and motion control. The system and molding die 1 are the same as the traditional rotary molding device. The temperature control system mainly includes air heating system, gas recovery cover 2, insulation layer 3, hot air distribution pipe 4, nozzle 5, hot air distribution pipe inlet pipe 9 And hot air distribution pipe outlet pipe 10, see figure 1 with figure 2 Shown. The air heating system heats the air to a set temperature and sends it to the hot air distribution pipe 4 through the air pipe 9 in the rotating spindle barrel 6 and the lower crank arm 8 and the hot air distribution pipe intake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com