Multi-layer combined impeller

A combined, impeller technology, used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as limited impeller height, avoid overall replacement, increase service life, and easily processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

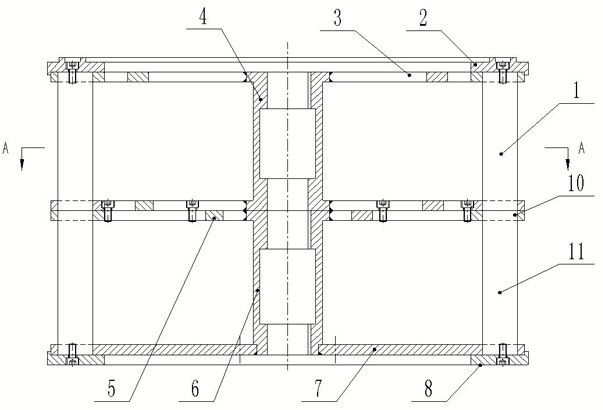

[0034] like Figure 1-3 Commonly shown, the present invention provides a multi-layer combined impeller, including several first impeller skeletons and a second impeller skeleton; several first impeller skeletons are connected sequentially from top to bottom; two adjacent first impeller skeletons The first impeller skeleton is connected to the second impeller skeleton by bolts; the first impeller skeleton is connected to the second impeller skeleton by bolts.

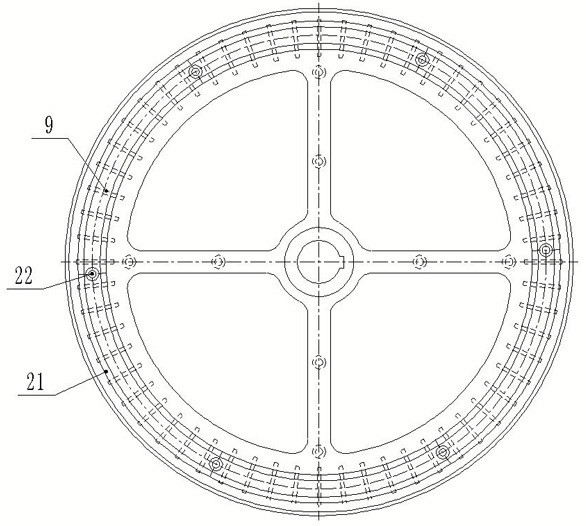

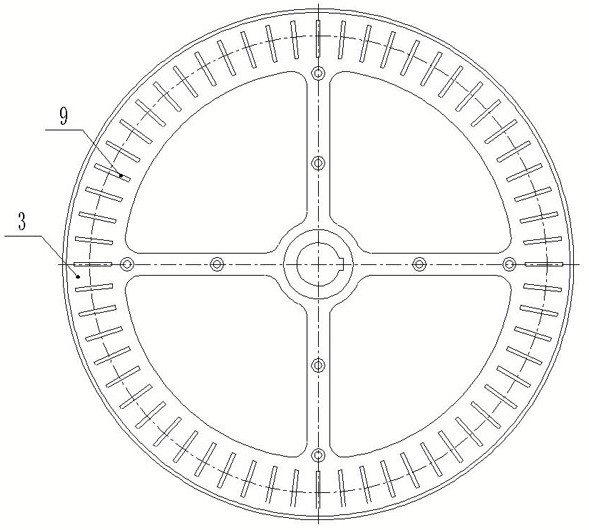

[0035] Both the first impeller frame and the second impeller frame are ring-shaped, and a plurality of slots are arranged on the first impeller frame and the second impeller frame along the circumferential direction, blades are inserted into the slots, and the The cross-sectional shape of the slot is the same as that of the blade.

[0036] The top of the uppermost first impeller skeleton is connected to the impeller labyrinth disc 2; the impeller labyrinth disc 2 is provided with a labyrinth ring 21 and a bolt hole 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com