Metal terminal rolling and packaging machine

A metal terminal and wrapping technology, which is applied in the field of metal terminal wrapping and wrapping machines, can solve the problems of low work efficiency and unguaranteed quality of metal terminal wrapping and wrapping, and achieve the effects of saving manpower, moderate tension and high control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

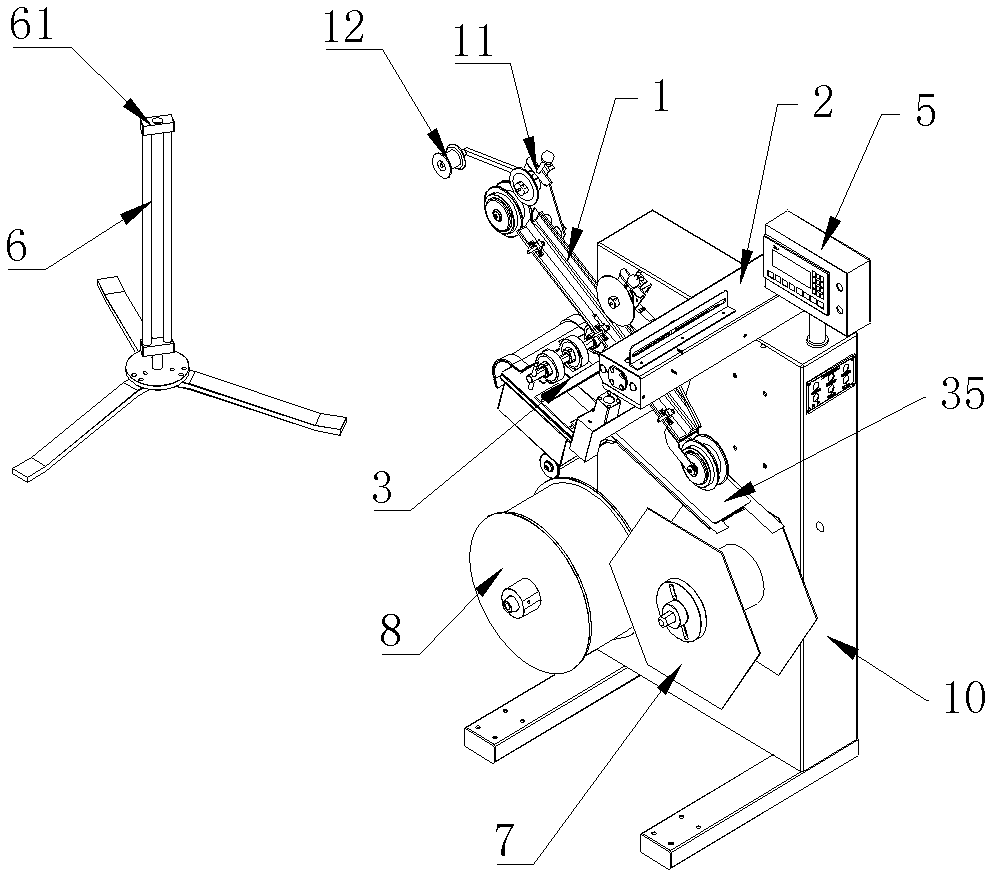

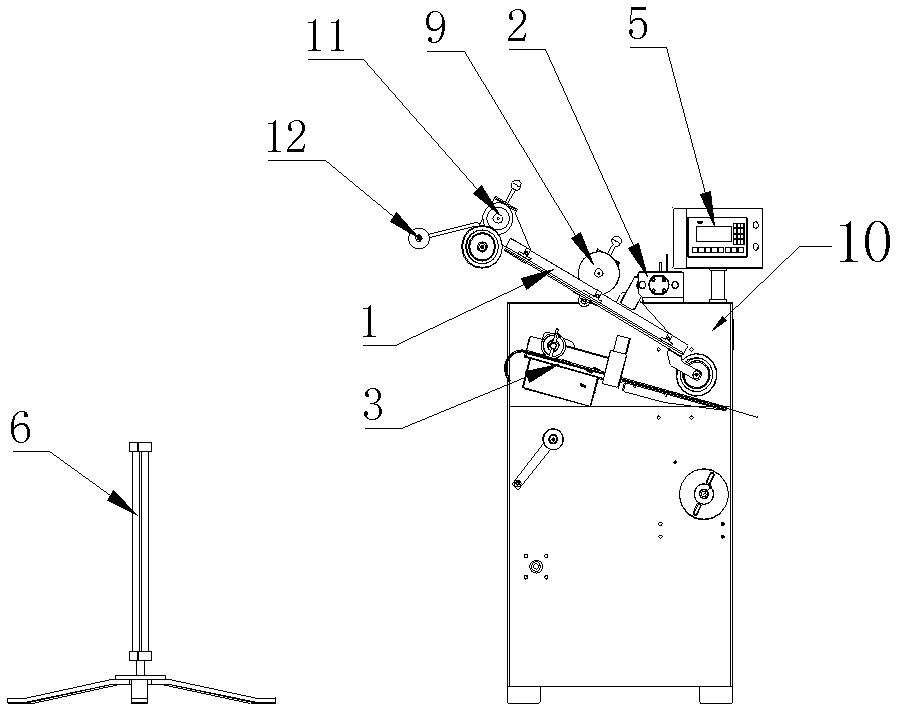

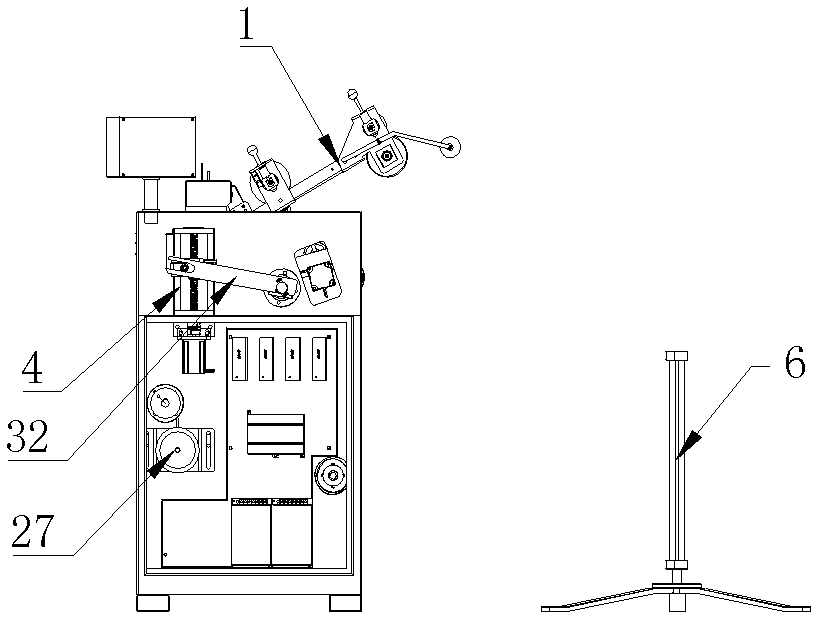

[0027] The invention provides a metal terminal winding and packaging machine, which can automatically connect the stamped metal terminal strings end to end into a chain shape, and wind them into rolls in multiple layers, and pass a layer of wrapping paper between the two layers of metal terminal strings. separated. The specific structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as figure 1 , figure 2 , image 3 As shown, the metal terminal rolling packaging machine provided by the present invention includes a main machine and a support 6. A tension detection device 61 is provided on the top of the support 6. The tension detection device 61 includes a base. The base has an opening slot facing the side, and the opening is The upper and lower walls of the slot are respectively equipped with inductors, and the chain-shaped metal terminal string passes through the open slot. Under normal working cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com