Cloth tension control device

A technology of tension control and cloth, which is applied in the direction of thin material handling, transportation and packaging, winding strips, etc., can solve the problems of speed out of sync, quality problems, etc., and achieve the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

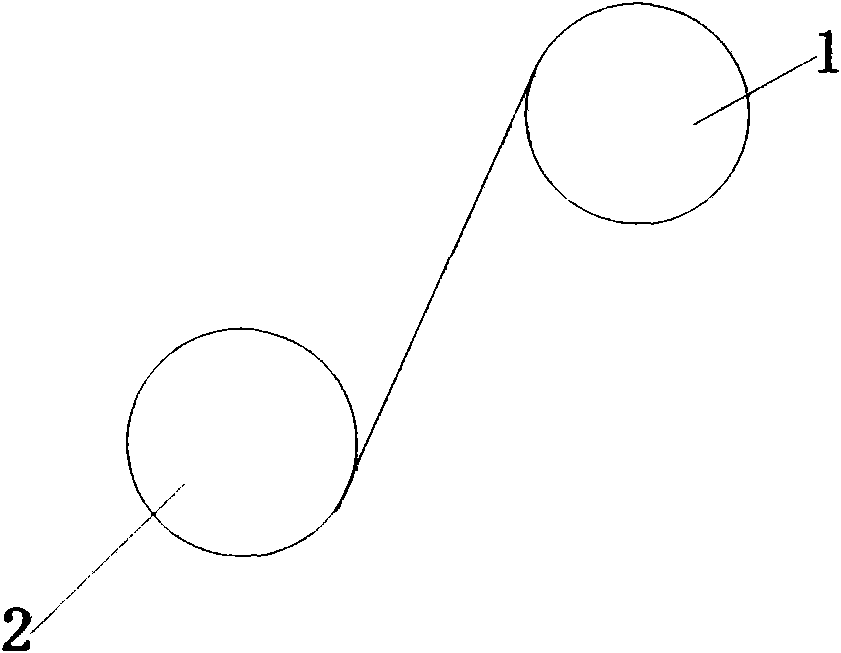

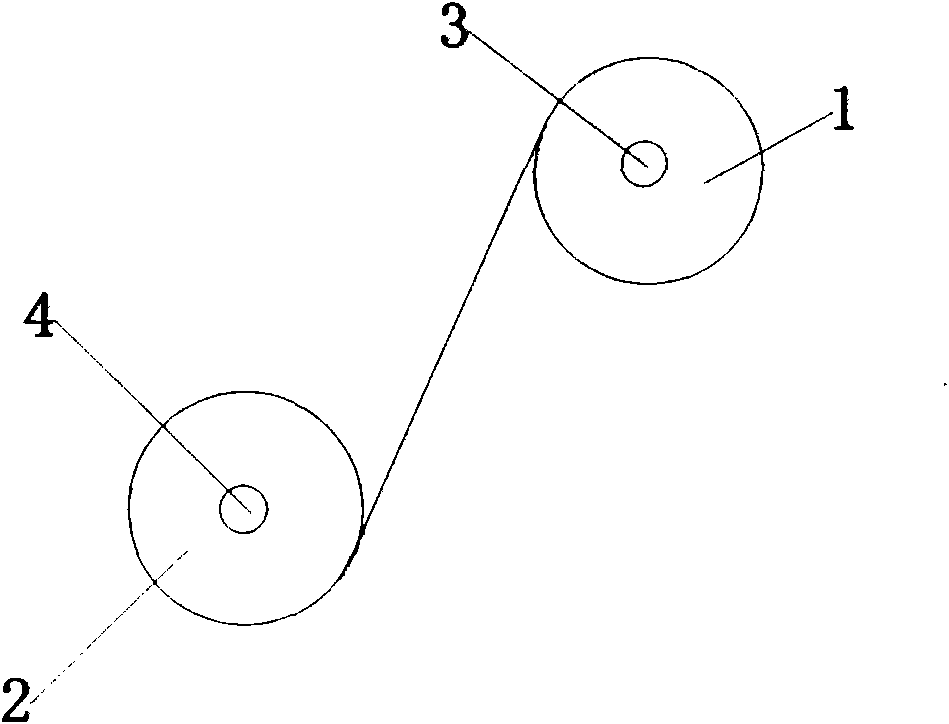

[0011] figure 2 A schematic diagram of installation of the cloth tension control device described in the present invention is shown. like figure 2 As shown, in the cloth take-up device, the cloth to be wound up is rolled onto the second roller 2 after passing around the first roller 1, and the first roller 1 and the second roller 2 are driven by the first driving unit and the second roller respectively. The second drive unit is pivotally driven.

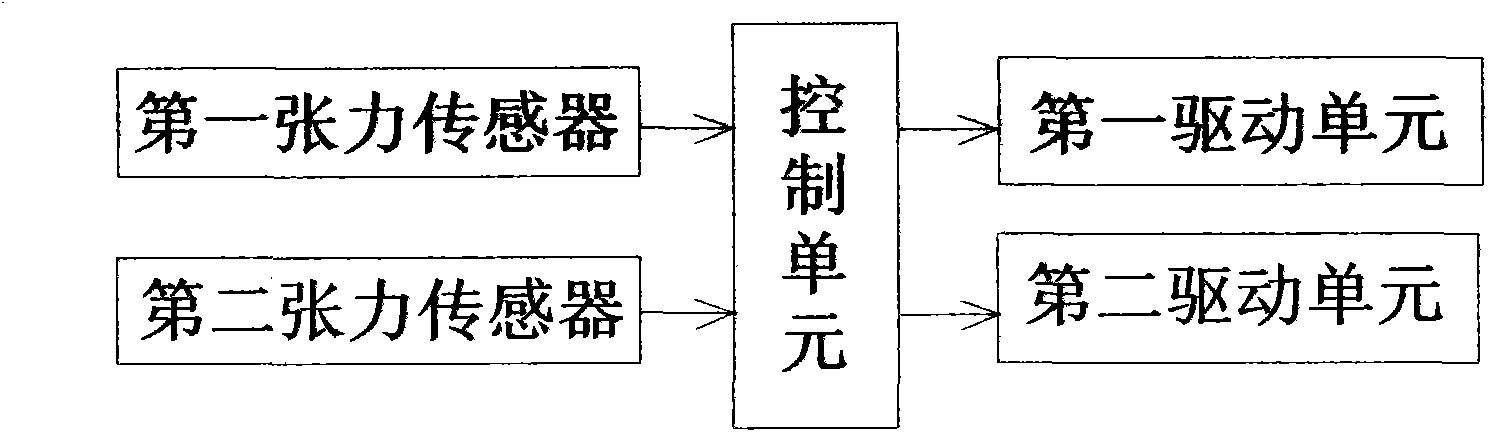

[0012] Figure 2-3 As shown, the cloth tension control device includes a control unit, and a first tension sensor 3 and a second tension sensor 4 electrically connected to the control unit; wherein, the control unit is used to drive the first and second tension sensors The rollers rotate at a predetermined speed, so as to achieve the purpose of adjusting the tension of the fabric; the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com