Zipper discharging device for bag making machine

A technology of a discharging device and a bag making machine, which is applied in the fields of zipper discharging device and zipper discharging device of a bag making machine, and can solve problems such as poor zipper discharging effect, low work efficiency, and affecting enterprise production efficiency and market competitiveness. , to achieve good discharging effect, reduce labor intensity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

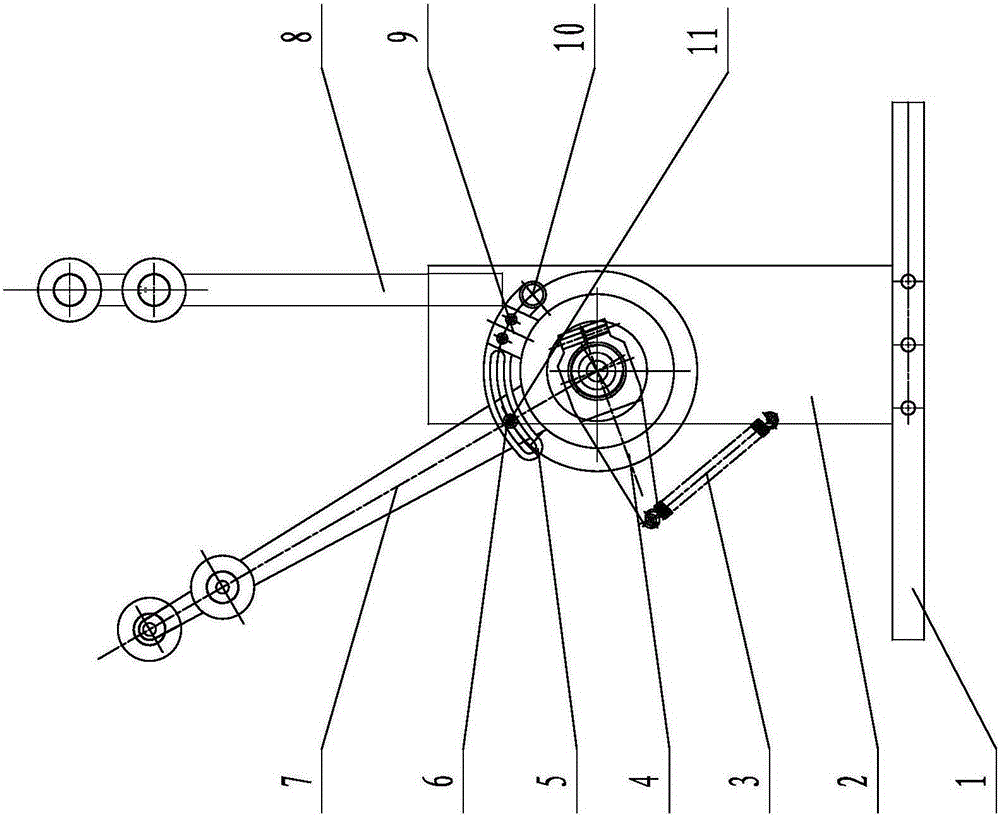

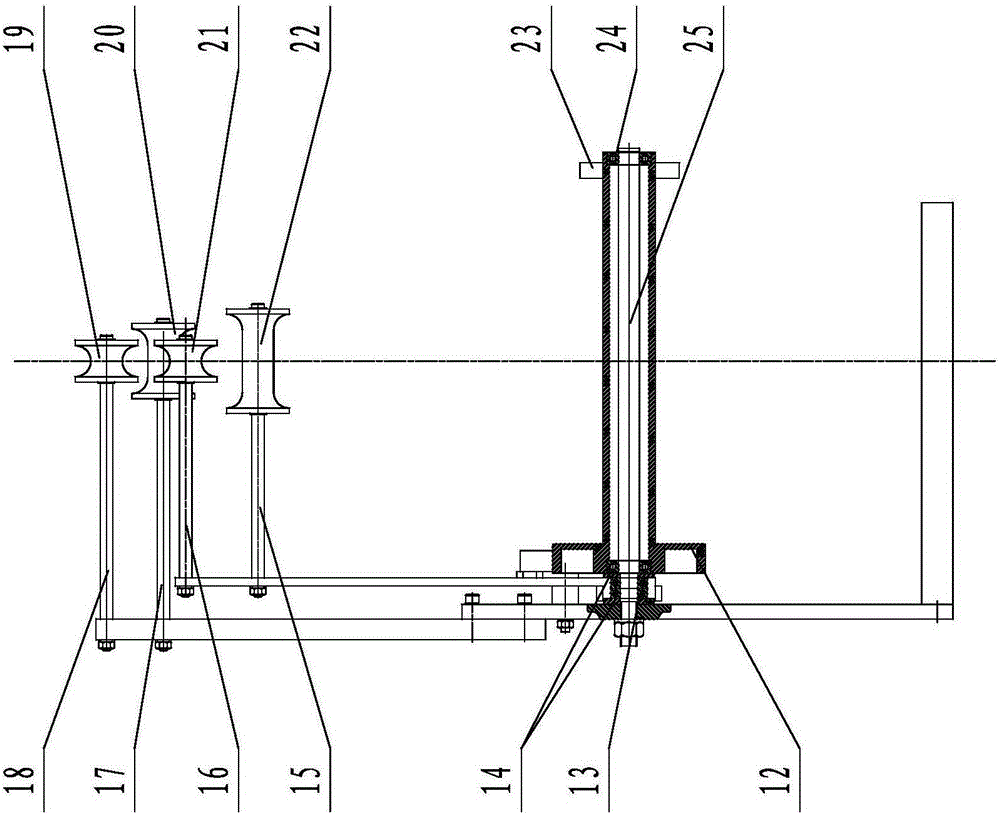

[0012] As shown in the figure: the zipper discharge device of the bag making machine in the embodiment is mainly composed of a bottom plate 1, a side plate 2, a tension spring 3, a swing arm 4, a locking seat 5, a first bearing 6, a swing rod 7, and a fixed rod 8 , brake block 9, shaft pin 10, small shaft 11, roller 12, second bearing 13, bearing limit ring 14, first moving guide roller shaft 15, second moving guide roller shaft 16, first fixed guide roller shaft 17. The second fixed guide roller shaft 18, the second fixed guide roller 19, the first fixed guide roller 20, the second moving guide roller 21, the first moving guide roller 22, the retaining ring 23, the third bearing 24 and the roller Shaft 25 and other components are formed.

[0013] Such as figure 1 , figure 2 As shown, the side plate 2 is fixed on the bottom plate 1 with screws, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com