Laser film laminator reloading device and control method thereof

A technology of laser laminator and laminator, which is applied in thin material handling, transportation and packaging, winding strips, etc., can solve problems such as finished product waste, and achieve the effects of reduced wear, convenient operation and great practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

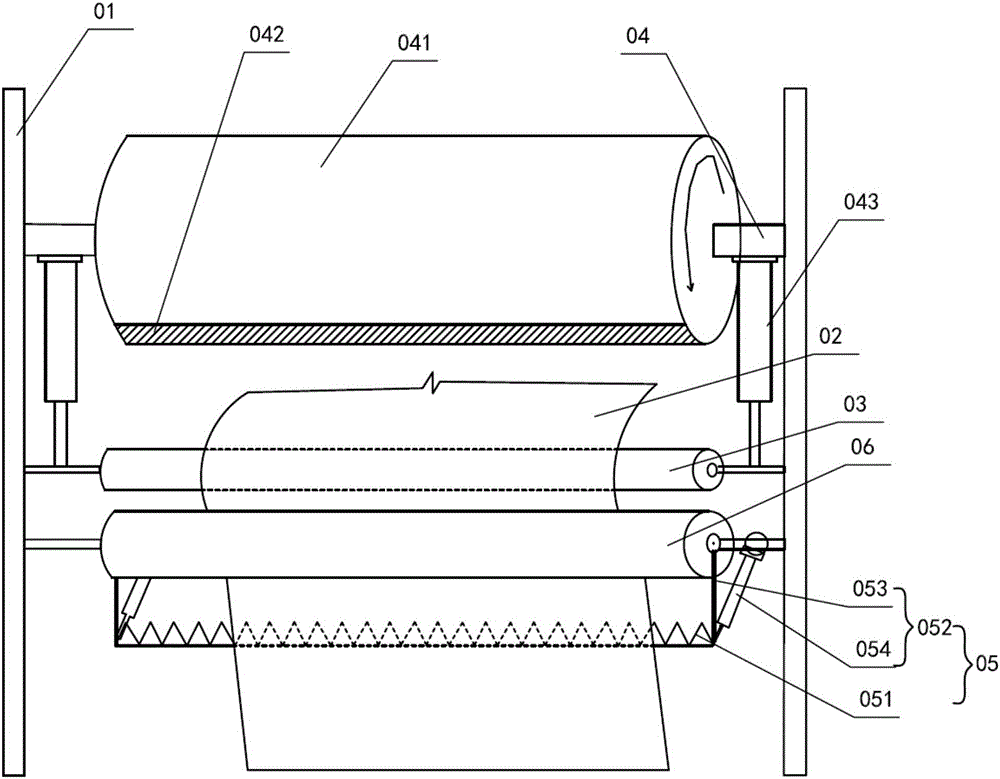

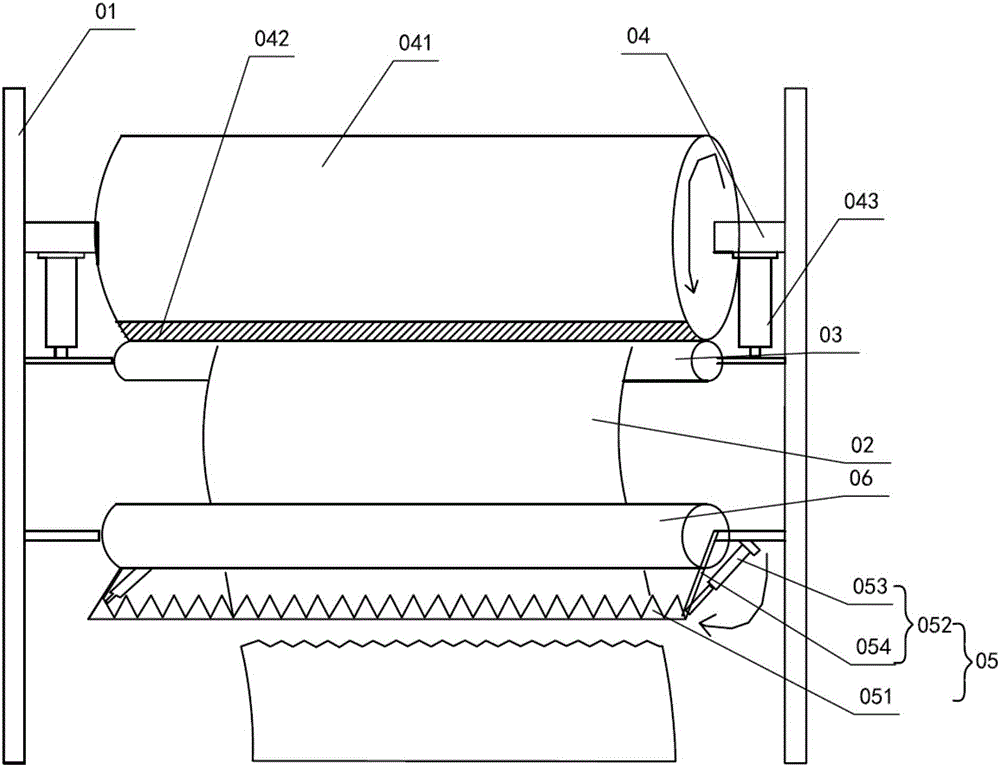

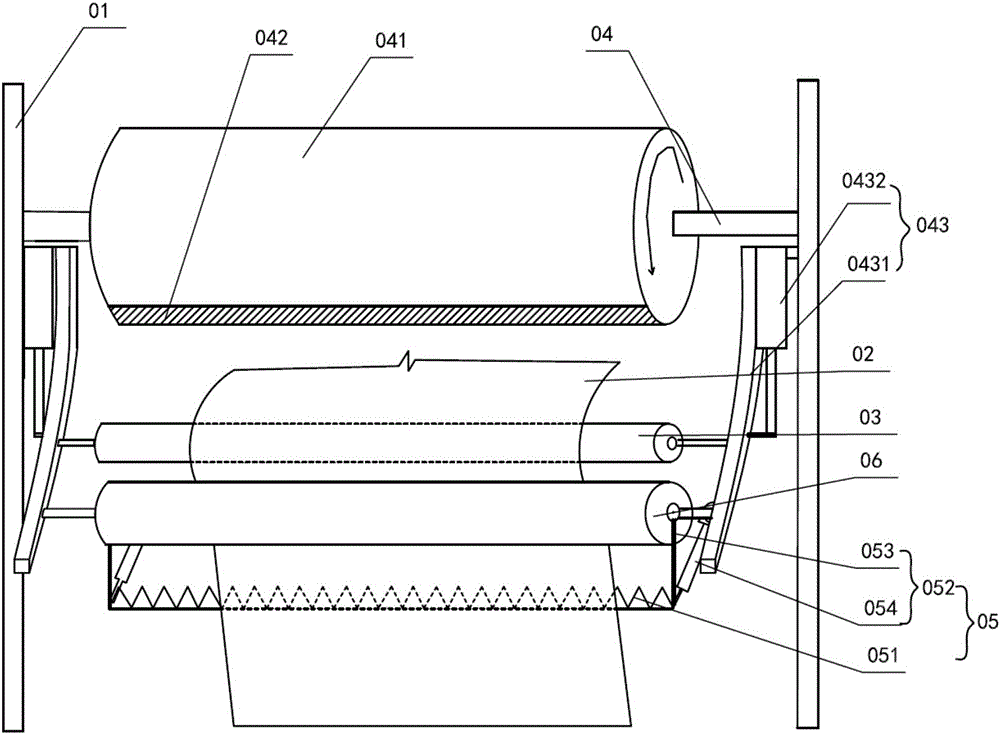

[0035] For the structural diagram of Embodiment 1 of the laser laminating machine refueling device of the present invention, see Figure 1 to Figure 2 , including two brackets 01 arranged vertically side by side, unwinding material 02 and transmission shaft 03 are arranged between the two brackets 01, unwinding material 02 is located above the transmission shaft 03, between the two brackets 01, The top of the conveying shaft 03 is provided with a film-leading shaft 04 parallel to it, and the frame 01 is provided with a film-leading shaft driving device for driving the film-leading shaft 04 to rotate. Before the rotation, the opposite surface of the leading film 041 and the transmission shaft 03 is provided with a double-sided adhesive tape 042, and the transmission shaft 03 is provided with a transmission shaft drive mechanism 043 for driving it to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com