Film supply device

A film sticking device and film supply technology, which is applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve the problems of film strip edge deviation, film strip easy deviation, curling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

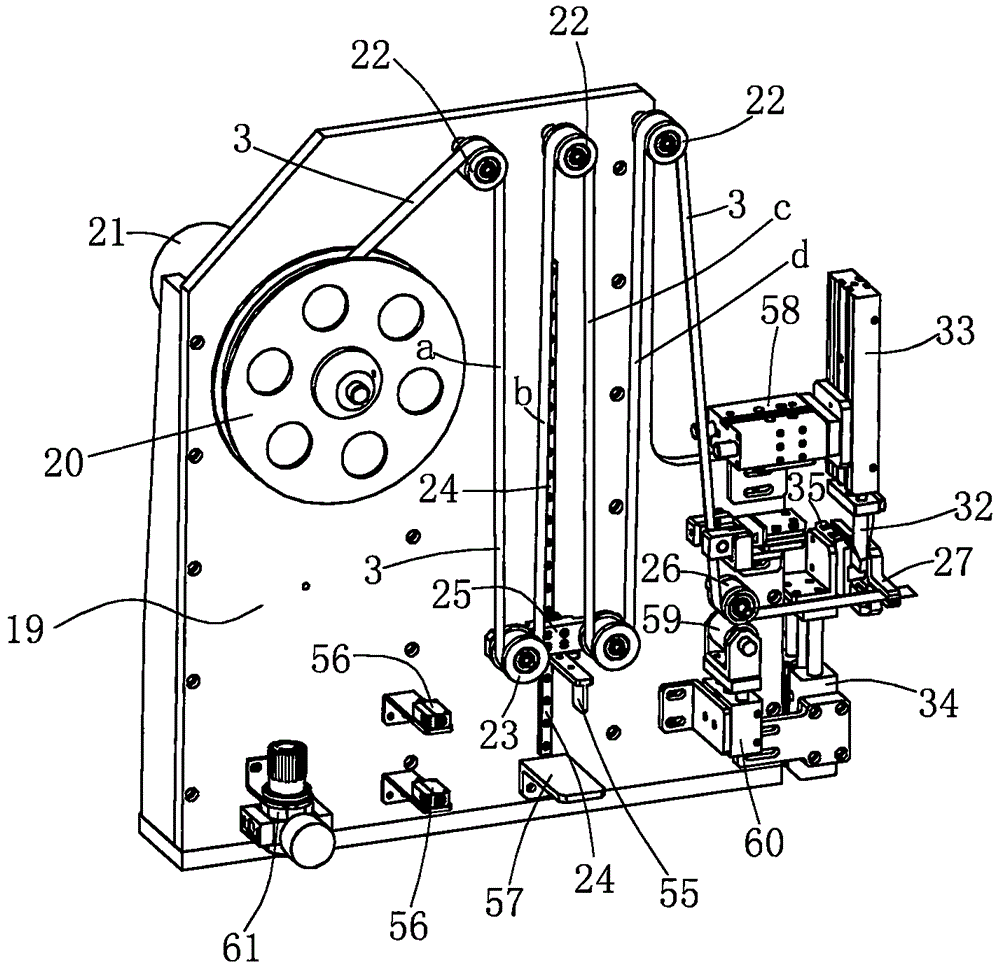

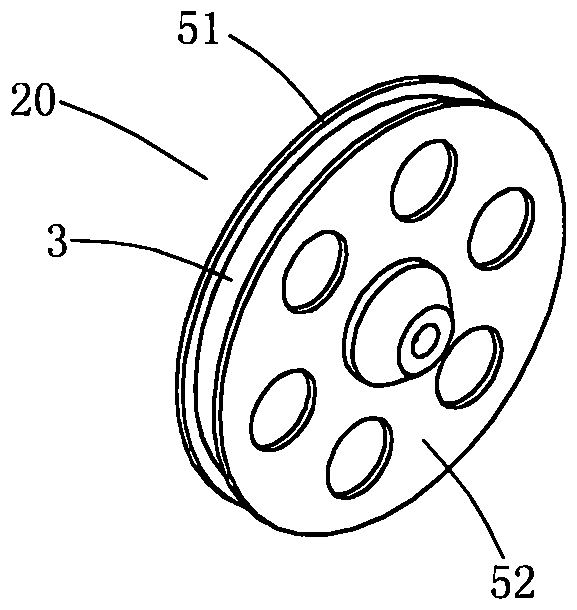

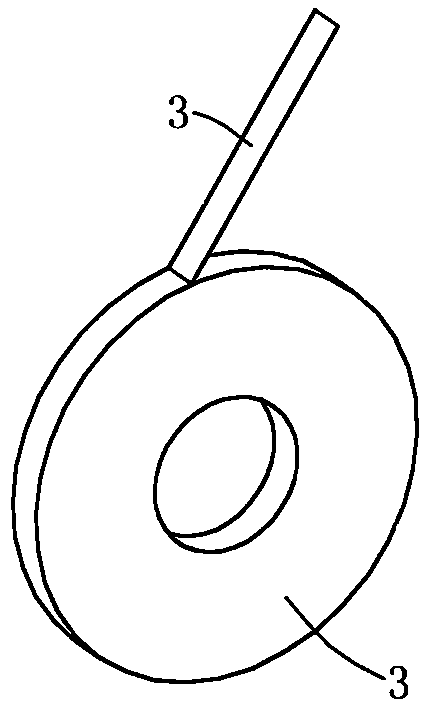

[0020] like figure 1 As shown, the film feeding device of the present invention includes a riser 19, and the riser 19 is equipped with: a sided bobbin 20 for installing the roll film belt 3, and a roller group tension mechanism for the film belt 3 to wind and form tension. The side bobbin 20 is fixedly installed on the rotating shaft driven by the servo motor 21 behind the vertical plate 19. The roller group tension mechanism includes three upper rollers 22 and two lower rollers 23 for the film belt 3 to wind around. The upper roller 22 in the middle position The vertical guide rail 24 and the slide block 25 that can slide up and down along the vertical guide rail 24 are arranged below, and the two lower rollers 23 are symmetrically installed on the slide block 25, and are respectively located on the left and right sides of the slide block 25; the film feeding mechanism It also includes a fifth roller 26 leading the film tape 3 to the film sticking mechanism.

[0021] Bordere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com