Deslagging structure and deslagging method for water seal tank of rotary hearth furnace

A technology for water-sealing tanks and rotary hearth furnaces, applied in the directions of furnaces, furnace types, furnace components, etc., can solve problems such as the ineffective operation of rotary hearth furnaces, and achieve the effects of reasonable structure, thorough slag discharge, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

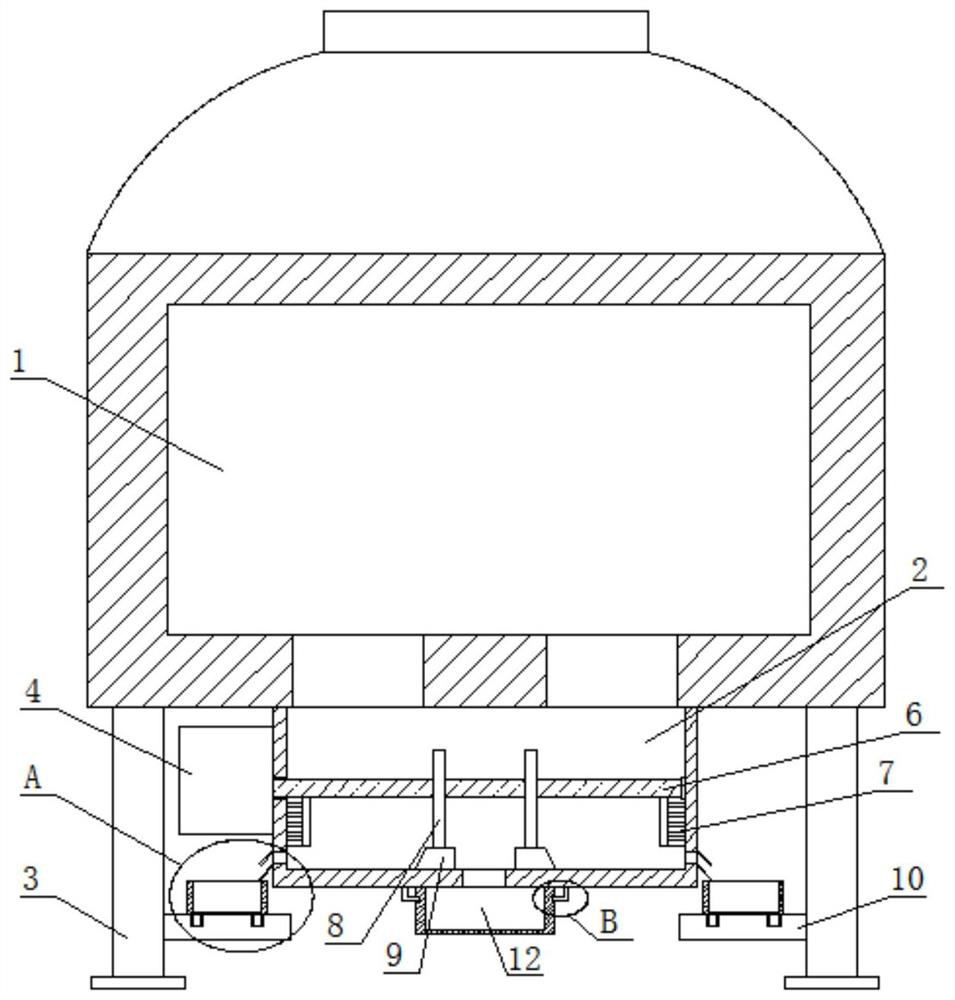

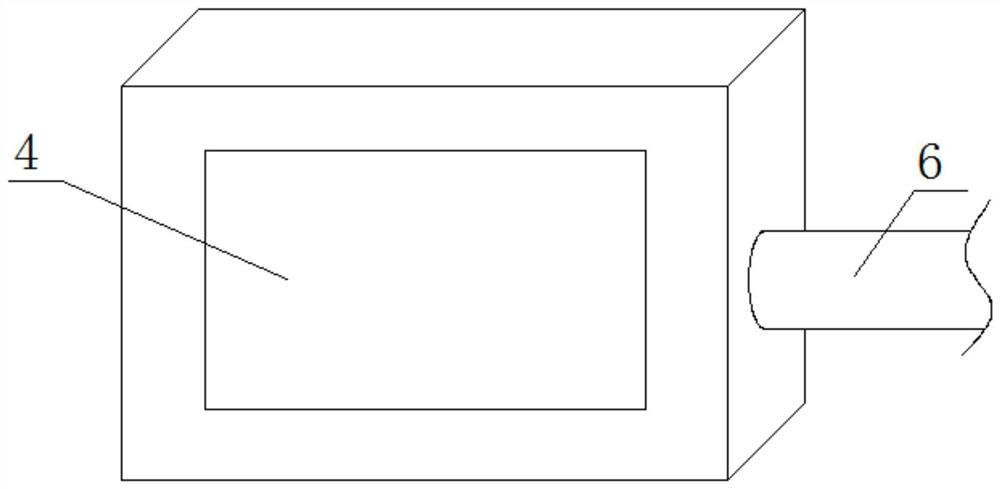

[0038] refer to Figure 1-5, a rotary hearth furnace water seal tank slagging structure, comprising a rotary hearth furnace main body 1, the bottom of the rotary hearth furnace main body 1 is provided with a water seal tank main body 2, and the bottom of the rotary hearth furnace main body 1 is symmetrically provided with two water seal The tank main body 2 is connected with a through hole, the bottom of the rotary hearth furnace main body 1 is symmetrically fixedly connected with two legs 3, one side of the water seal tank main body 2 is fixedly connected with a fixed seat 4, and a fixed chamber is arranged on the fixed seat 4 5. There is a power assembly on the fixed chamber 5, and a rotating shaft 6 is connected to the power assembly. One end of the rotating shaft 6 extends into the main body 2 of the water seal tank and is rotationally connected with one side of the inner wall of the main body 2 of the water seal tank. On the rotating shaft 6 Two cleaning brushes 7 are sym...

Embodiment 2

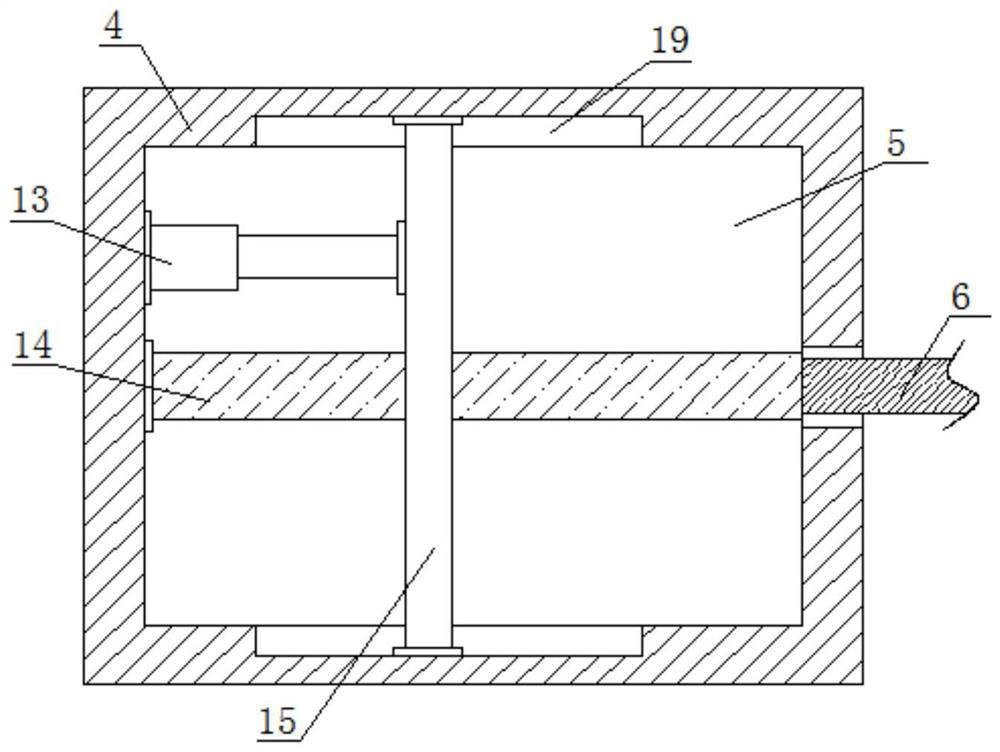

[0040] In the present invention, the power assembly includes an electric telescopic rod 13 fixedly connected to the inner wall of one side of the fixed chamber 5 and a ball screw 14 rotatably connected to the inner wall of one side of the fixed chamber 5. The ball screw 14 is threadedly connected with Lead screw nut 15, one end of the electric telescopic rod 13 is fixedly connected with one side of the lead screw nut 15, the other end of the rotating shaft 6 extends into the fixed chamber 5 and is fixedly connected with one end of the ball screw 14, the electric telescopic rod 13, The screw nut 15 can be moved back and forth, and the ball screw 14 can drive the rotating shaft 6 to rotate back and forth, so as to provide power for the rotating shaft 6 .

[0041] In the present invention, both sides of the main body 2 of the water seal tank 2 are symmetrically fixedly connected with two limiting plates 18, and the slag discharge port is located between the two limiting plates 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com