Telephone receiver acoustic testing device and telephone receiver acoustic testing system

A technology of acoustic testing and receivers, applied in the direction of electrical components, etc., can solve problems such as large measurement errors, hidden dangers of product quality, test distortion stability, etc., and achieve accurate sensitivity, accurate test results, and high test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides an acoustic testing device for a receiver, including a driving device and an output device.

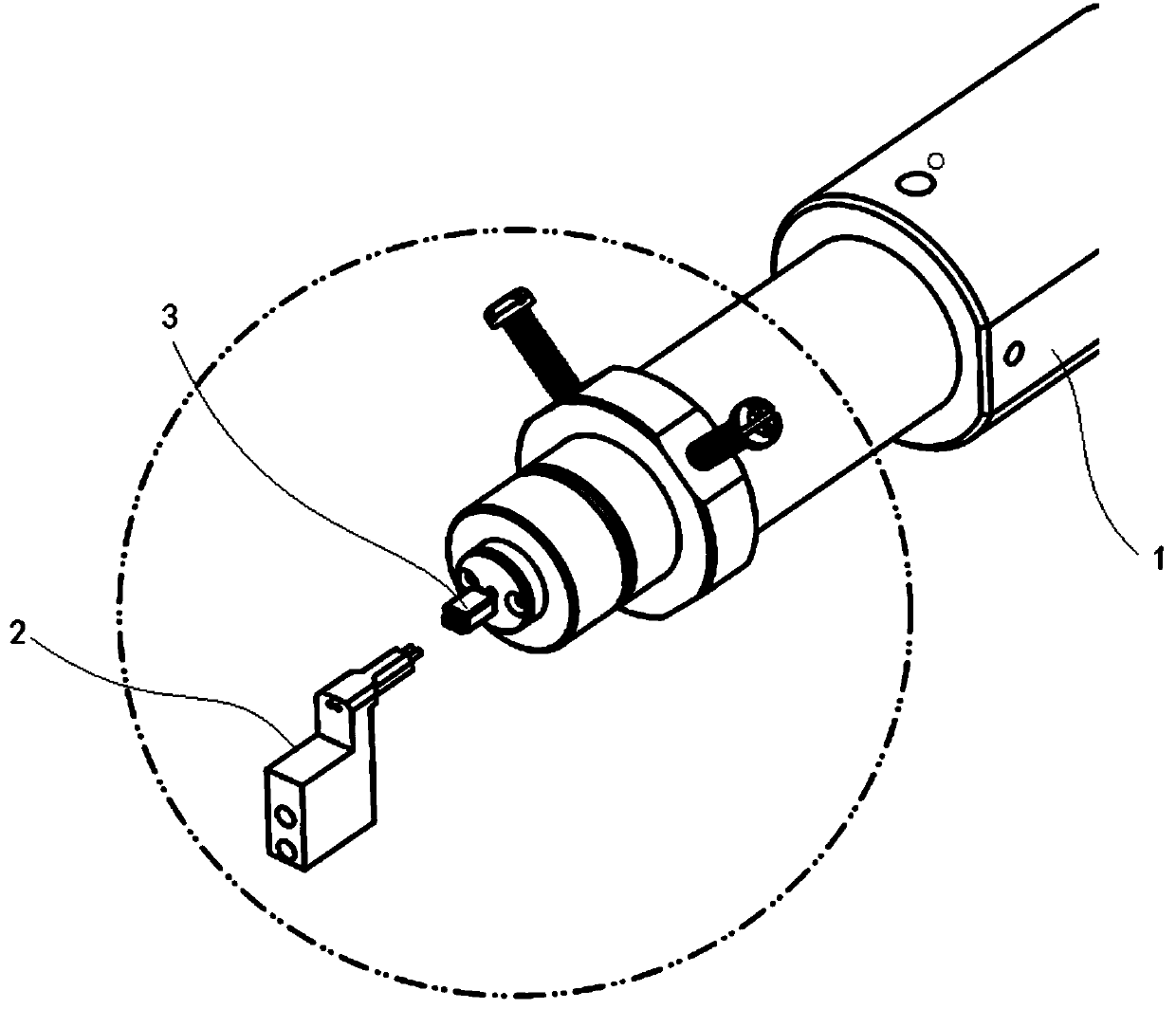

[0039] like Figure 4 As shown, the tested receiver 50 includes a pair of circuit terminals 52 and a sound tube 54 protruding from the shell.

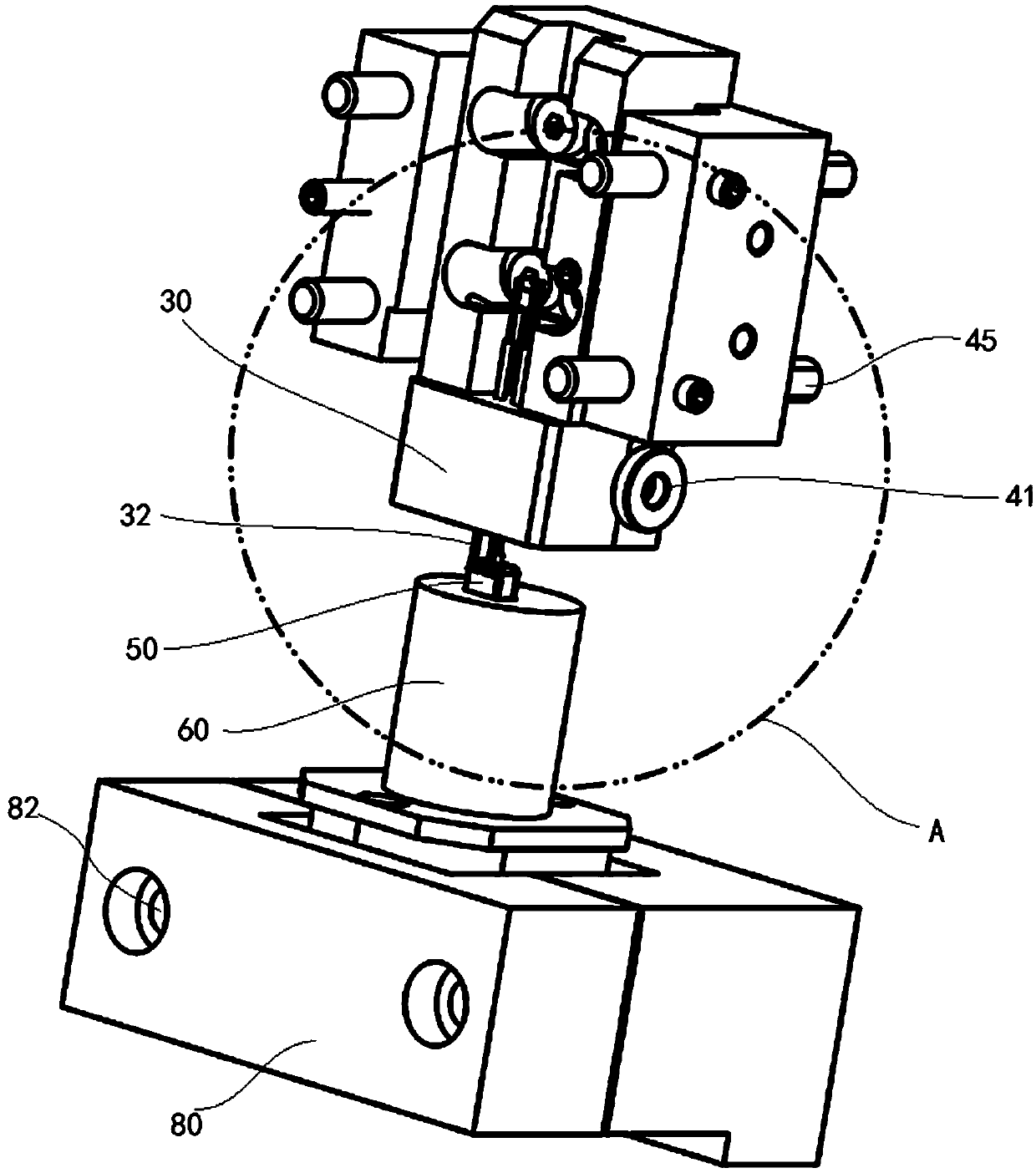

[0040] Please refer to 2 and Figure 5 , the driving device includes a bracket 10, a guide rail 12, a pressing assembly and a test adjustment device. In this embodiment, the guide rail 12 is installed vertically on the bracket 10 . Vertical rails are arranged on the bracket 10, and the guide rails 12 are slidably installed on the vertical rails.

[0041]The lower end of the guide rail 12 is fixed with a pressing component for inputting test signals. The pressing component adjusts the docking position of the receiver under test through the test adjusting device.

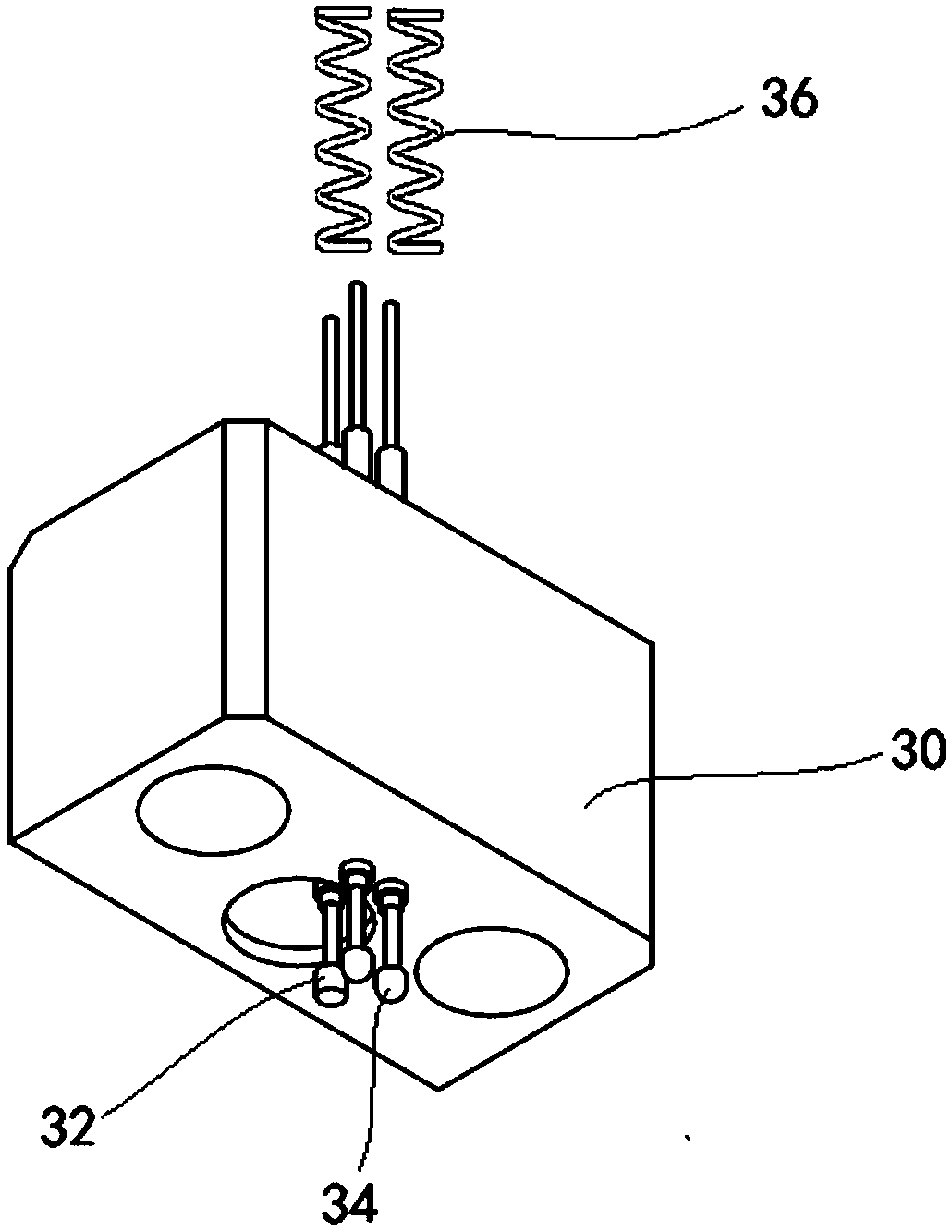

[0042] Please refer to image 3 , the pressing assembly includes a pressing head 30 fixed on the guide rail 12 , a positioning column 32 adjustab...

Embodiment 2

[0062] This embodiment relates to an acoustic test system using the receiver acoustic test device, including a test terminal and several test sensors.

[0063] The test terminal is connected to the drive cylinder of the receiver acoustic test device. The test terminal is connected to a position sensor disposed in the coupling cavity 64 close to the sealing ring 70 . One end of the test pin 34 of the receiver acoustic test device is connected to the signal input end of the test terminal, and the test sensor of the acoustic test system is arranged in the coupling cavity 64 or the extension coupling cavity 86 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com