Method for controlling temperature of slag flushing water at cooling tower outlet in blast furnace slag treating system

A technology of processing system and cooling tower, which is applied in the field of blast furnace slag processing system, can solve the problems of inability to meet the requirements of temperature control accuracy, reaction speed and automation of slag flushing water at the outlet of cooling tower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

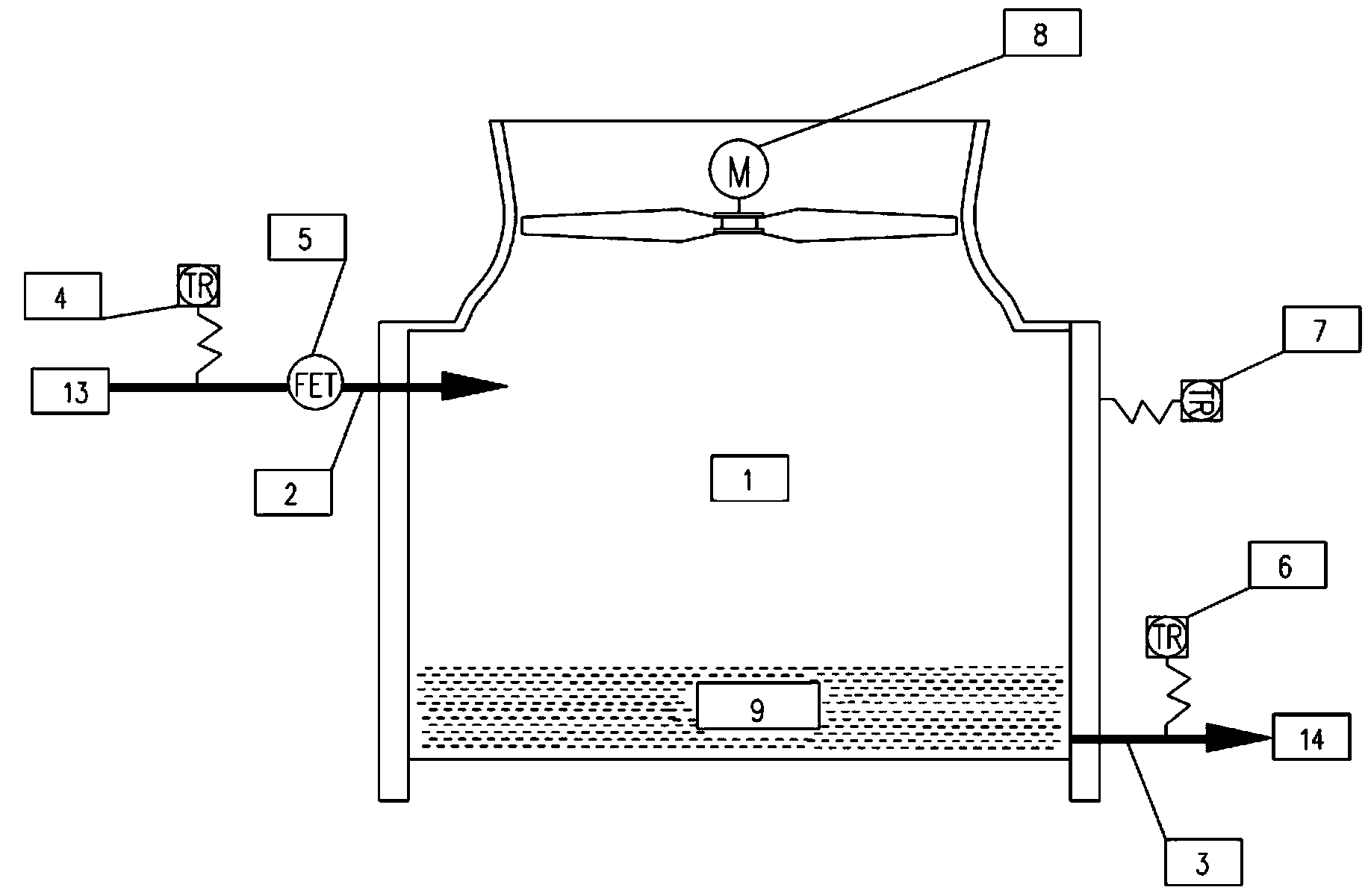

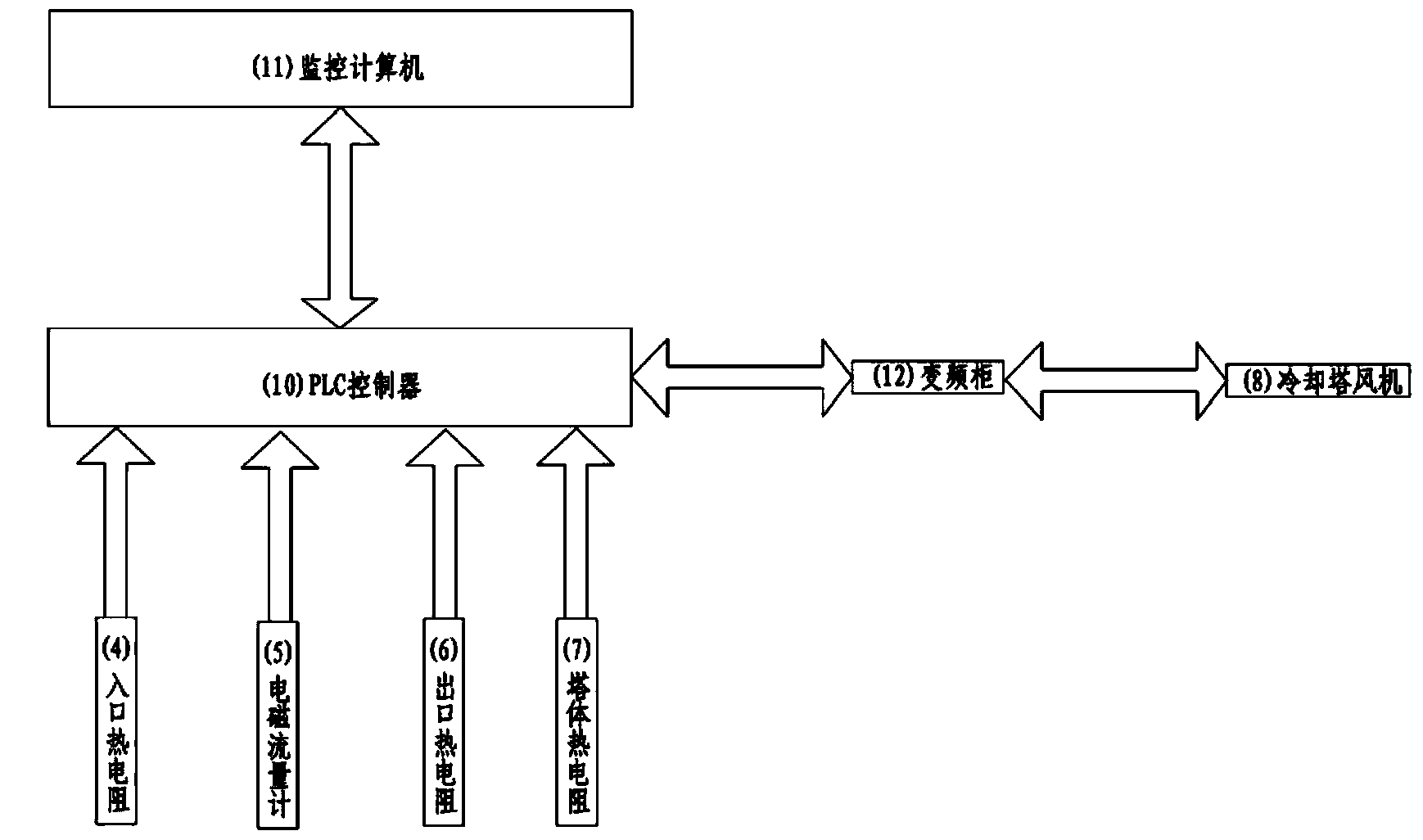

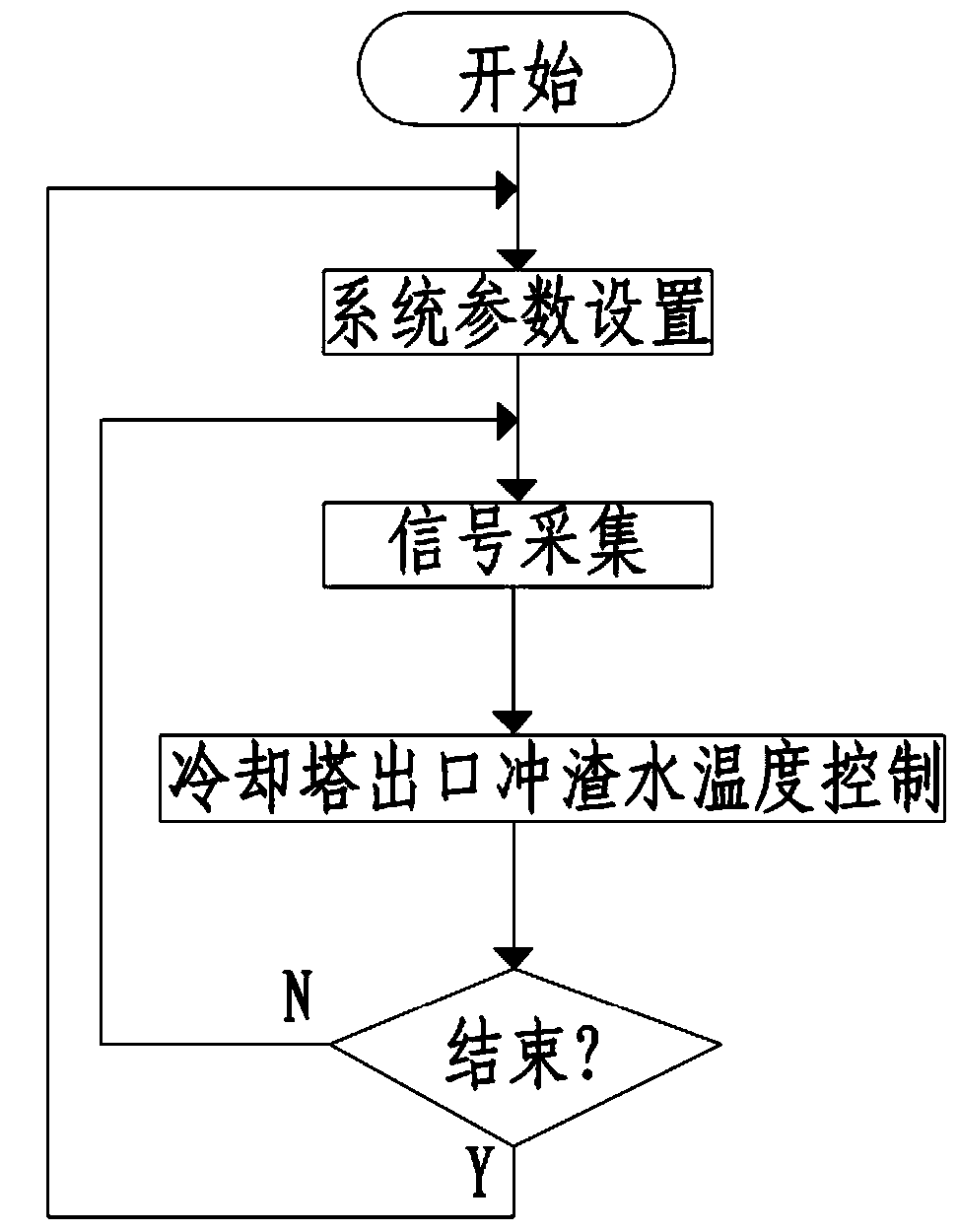

[0054] The control system in which the control method is located is such as figure 1 , figure 2 shown. A temperature control system for slag flushing water at the outlet of a cooling tower of a blast furnace slag treatment system, the cooling tower includes a cooling tower body 1, an inlet slag flushing water branch pipe 2 and an outlet slag flushing water branch pipe 3, and the slag flushing water for the cooling tower body 1 The inlet is connected to the inlet slag flushing water branch pipe 2, and the slag flushing water branch pipe 3 of the cooling tower body 1 is connected to the outlet slag flushing water branch pipe 3. There is an outlet detection device, and the tower body 1 of the cooling tower is connected with a tower body detection device; the above-mentioned detection devices are connected to the monitoring computer 11 through the PLC controller 10, and the PLC controller 10 (with a memory database on it) is also connected to the cooling tower fan 8 connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com