Morphology controllable nanometer CeO2 preparation method

A nano and morphology technology, applied in the direction of nanotechnology, chemical instruments and methods, sustainable manufacturing/processing, etc., to achieve the effects of simplified production process, strong environmental protection and economic applicability, and reduced agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

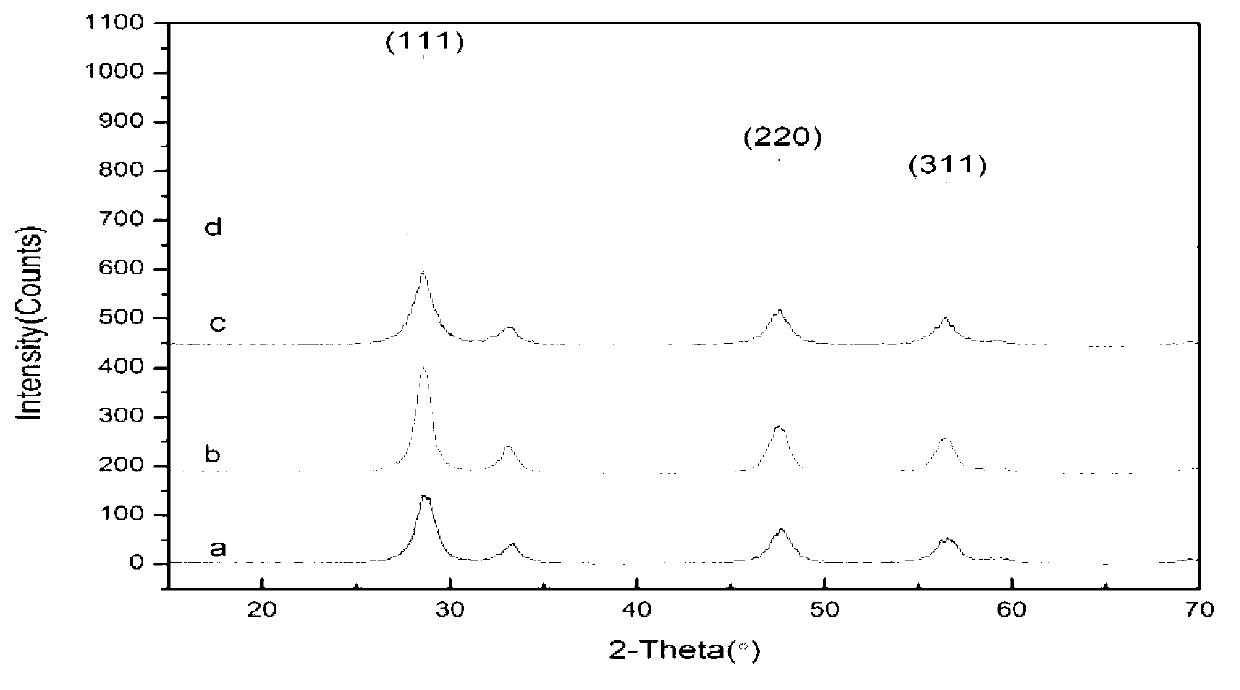

Image

Examples

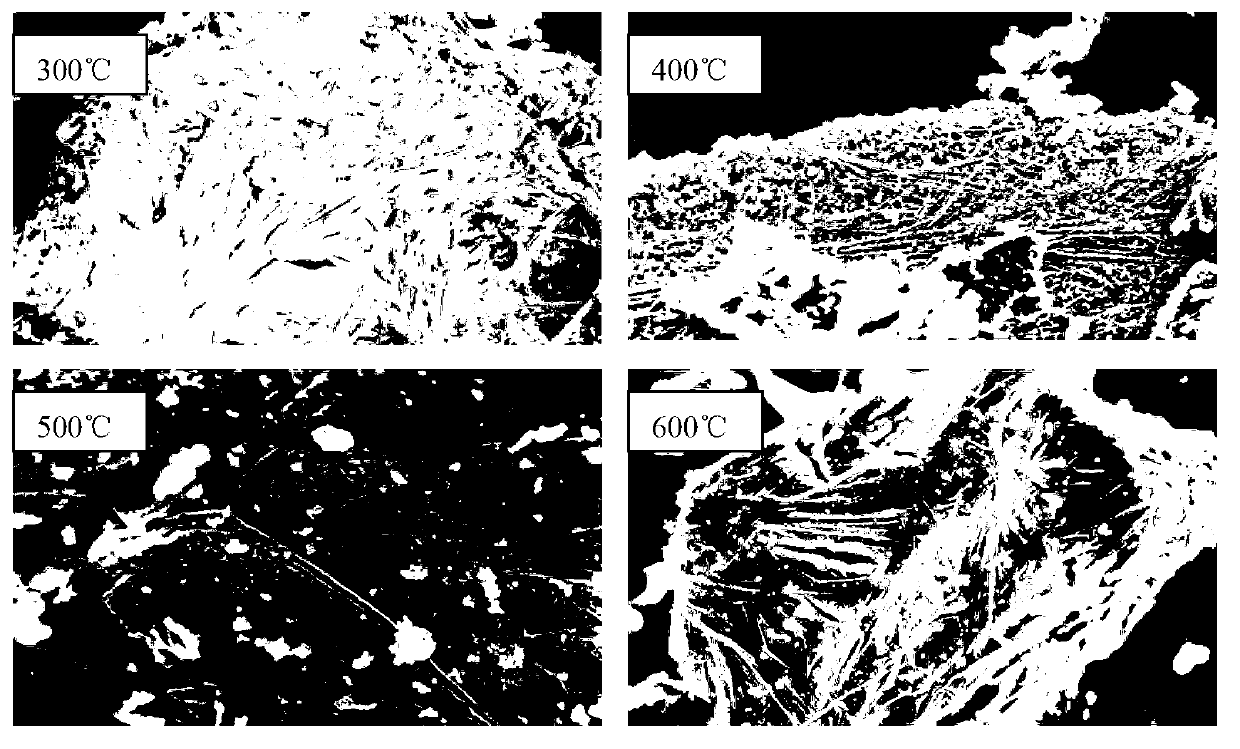

Embodiment 1

[0016] 1) First, take 8.69g of cerium nitrate hexahydrate and 16.81g of citric acid and dissolve them in 100ml of deionized water to prepare cerium nitrate and citric acid solutions;

[0017] 2) Then slowly add the cerium nitrate solution into the citric acid solution under stirring, stir evenly at 65°C, add ammonia water dropwise, adjust the pH value to 2.0, then put it in a water bath and stir at 80°C until the reaction occurs Sol, put the formed sol into a drying oven and dry at 100°C to form a xerogel;

[0018] 3) The above-mentioned xerogel was fired in a muffle furnace from room temperature to 300°C at a heating rate of 3°C / min for 2 hours to obtain light yellow CeO 2 , Grind the roasted product with a mortar, and finally get a light yellow CeO 2 powder.

Embodiment 2

[0020] 1) First, take 8.69g of cerium nitrate hexahydrate and 16.81g of citric acid and dissolve them in 100ml of deionized water to prepare cerium nitrate and citric acid solutions;

[0021] 2) Then slowly add the cerium nitrate solution into the citric acid solution under stirring, stir evenly at 65°C, add ammonia water dropwise, adjust the pH value to 2.3, then put it in a water bath and stir at 80°C until the reaction occurs Sol, put the formed sol into a drying oven and dry at 100°C to form a xerogel;

[0022] 3) The above-mentioned xerogel was fired in a muffle furnace from room temperature to 400°C at a heating rate of 4°C / min for 2 hours to obtain light yellow CeO 2 , Grind the roasted product with a mortar, and finally get a light yellow CeO 2 powder.

Embodiment 3

[0024] 1) First, take 8.69g of cerium nitrate hexahydrate and 16.81g of citric acid and dissolve them in 100ml of deionized water to prepare cerium nitrate and citric acid solutions;

[0025] 2) Then slowly add the cerium nitrate solution into the citric acid solution under stirring, stir evenly at 65°C, add ammonia water dropwise, adjust the pH value to 2.5, then put it in a water bath and stir at 80°C until the reaction occurs Sol, put the formed sol into a drying oven and dry at 100°C to form a xerogel;

[0026] 3) The above-mentioned xerogel was fired in a muffle furnace from room temperature to 500°C at a heating rate of 5°C / min for 2 hours to obtain light yellow CeO 2 , Grind the roasted product with a mortar, and finally get a light yellow CeO 2 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com