Waterborne epoxy resin for stoving varnish and preparation method and application

A water-based epoxy resin and epoxy resin technology, used in epoxy resin coatings, coatings, etc., can solve the problems of low VOC, many organic solvents, and unenvironmental protection of water-dispersed epoxy resins, and achieve consistent performance and low VOC. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 10

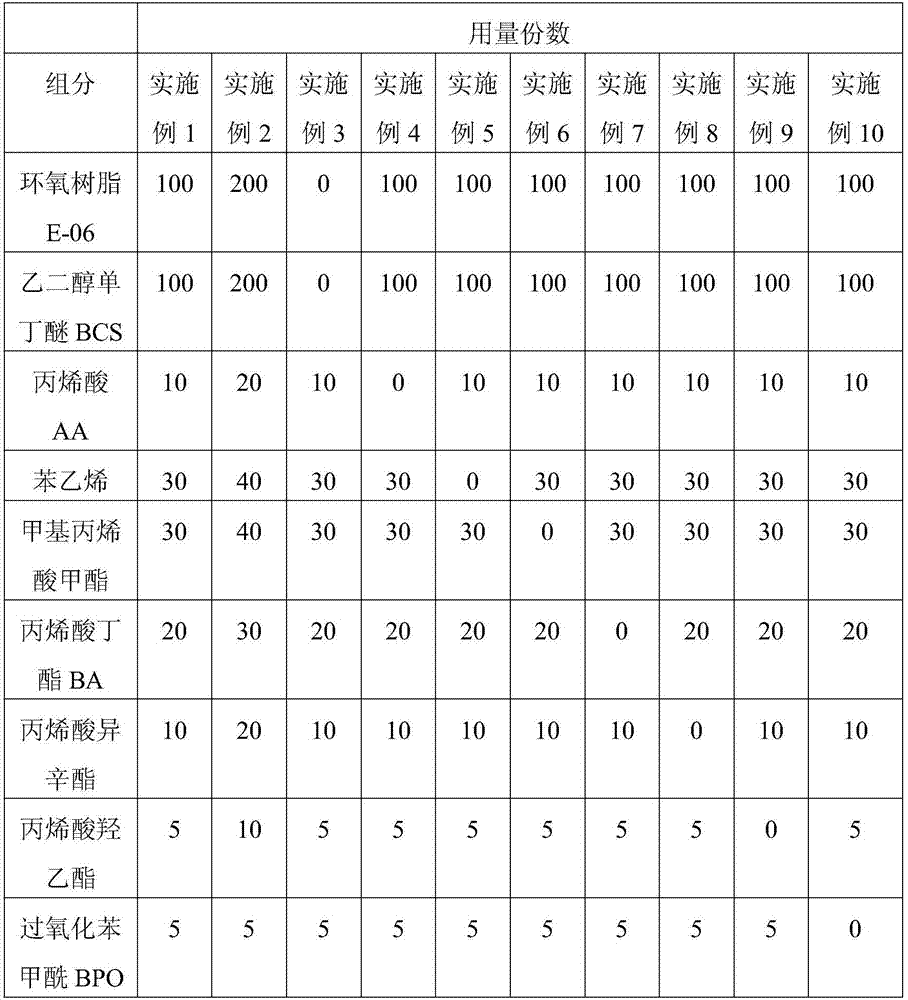

[0024] Prepare 10 different epoxy resins for baking varnishes, which are used as shown in Table 1.

[0025] Table 1 Preparation of water-based epoxy resin raw material components and their proportions for baking varnish

[0026]

[0027] 1. The preparation method of water-based epoxy resin for baking varnish, the steps are as follows:

[0028] (1) Dissolve epoxy resin E-06 in ethylene glycol monobutyl ether BCS according to the 10 parts by weight in the above table 1, heat to 120°C, and stir for 15 minutes;

[0029] (2) Stir and mix acrylic acid, styrene, methyl methacrylate, butyl acrylate, isooctyl acrylate, hydroxyethyl acrylate, and benzoyl peroxide, and add dropwise to step (1) at 120°C to mix evenly In the solution, the dropping time is 2 to 2.5 hours; then the temperature is kept at 120°C for 3 hours, and a small amount of benzoyl peroxide is added during the heat preservation reaction to completely polymerize the monomer;

[0030] (3) Then cool down to 60°C, add d...

Embodiment 11

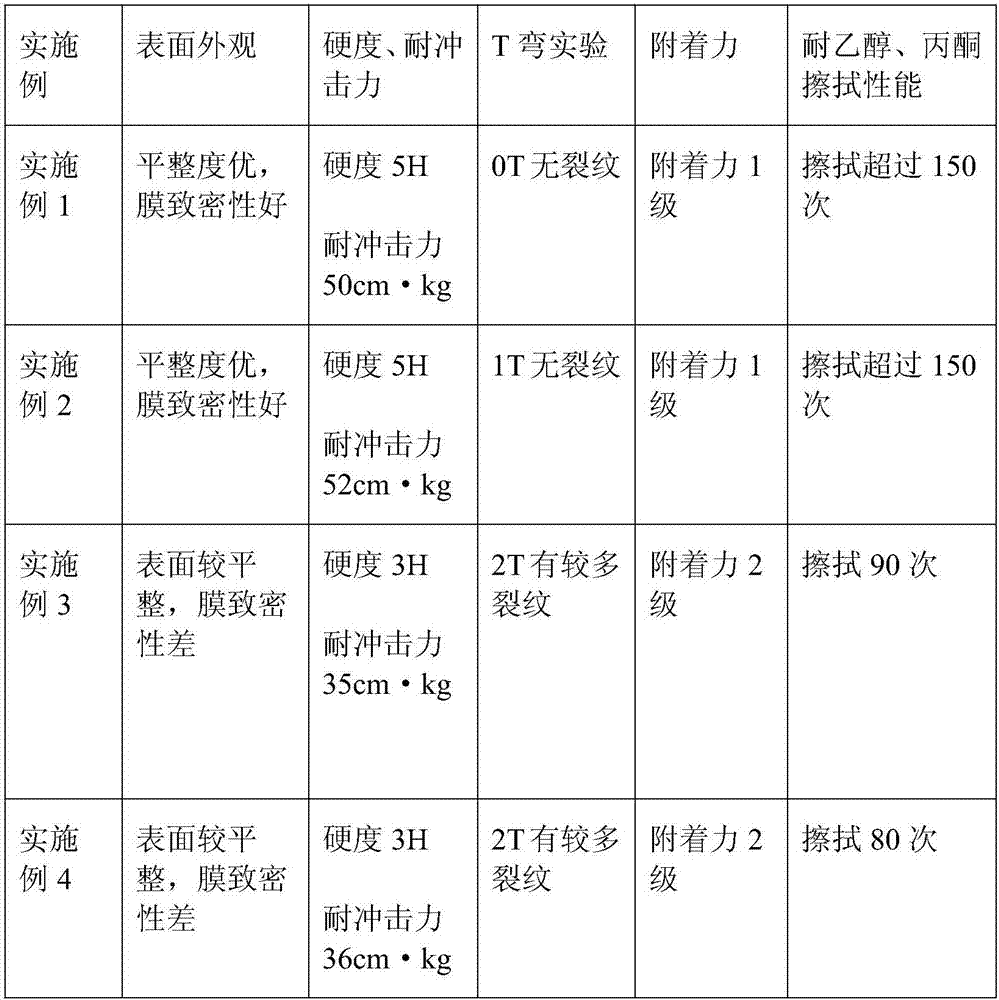

[0033] Embodiment 11 performance test, concrete steps are as follows:

[0034] 1. Get 10 parts of tinplate and polish it smooth, remove the surface oxide layer; use the coating wire bar to scrape the water-based epoxy resin for baking varnish prepared in Examples 1 to 10 respectively to obtain an epoxy resin varnish film, and after the paint film is cured The thickness is between 15 and 20 μm;

[0035] 2. After coating, put it in a 50°C oven to preheat for 10 minutes to avoid surface defects caused by direct high-temperature heating, and then put the preheated substrate at 270°C for 40 seconds to cure;

[0036] The following properties were measured for the paint film cured according to the above steps:

[0037] (1) Surface appearance; (2) Hardness, impact resistance; (3) T-bend test; (4) Adhesion; (5) Ethanol, acetone wiping resistance;

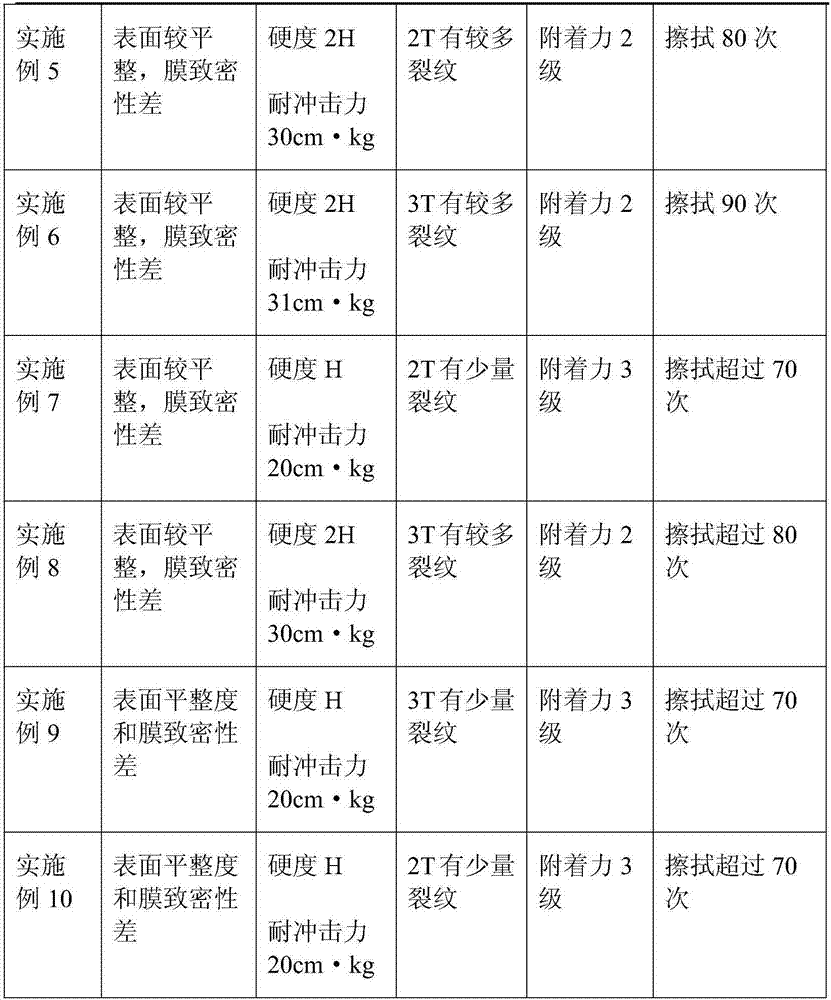

[0038] The specific inspection results are shown in Table 2:

[0039]

[0040]

[0041] Show by above performance test result, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com