High voltage pulse thyristor switching device with thermal management

A high-voltage pulse and switching device technology, applied in thyristors, semiconductor devices, electric solid devices, etc., can solve the problems of large cooling system, small time scale, large energy consumption of cooling system, etc., to strengthen cooling effect and reduce heat conduction. Thermal resistance, the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

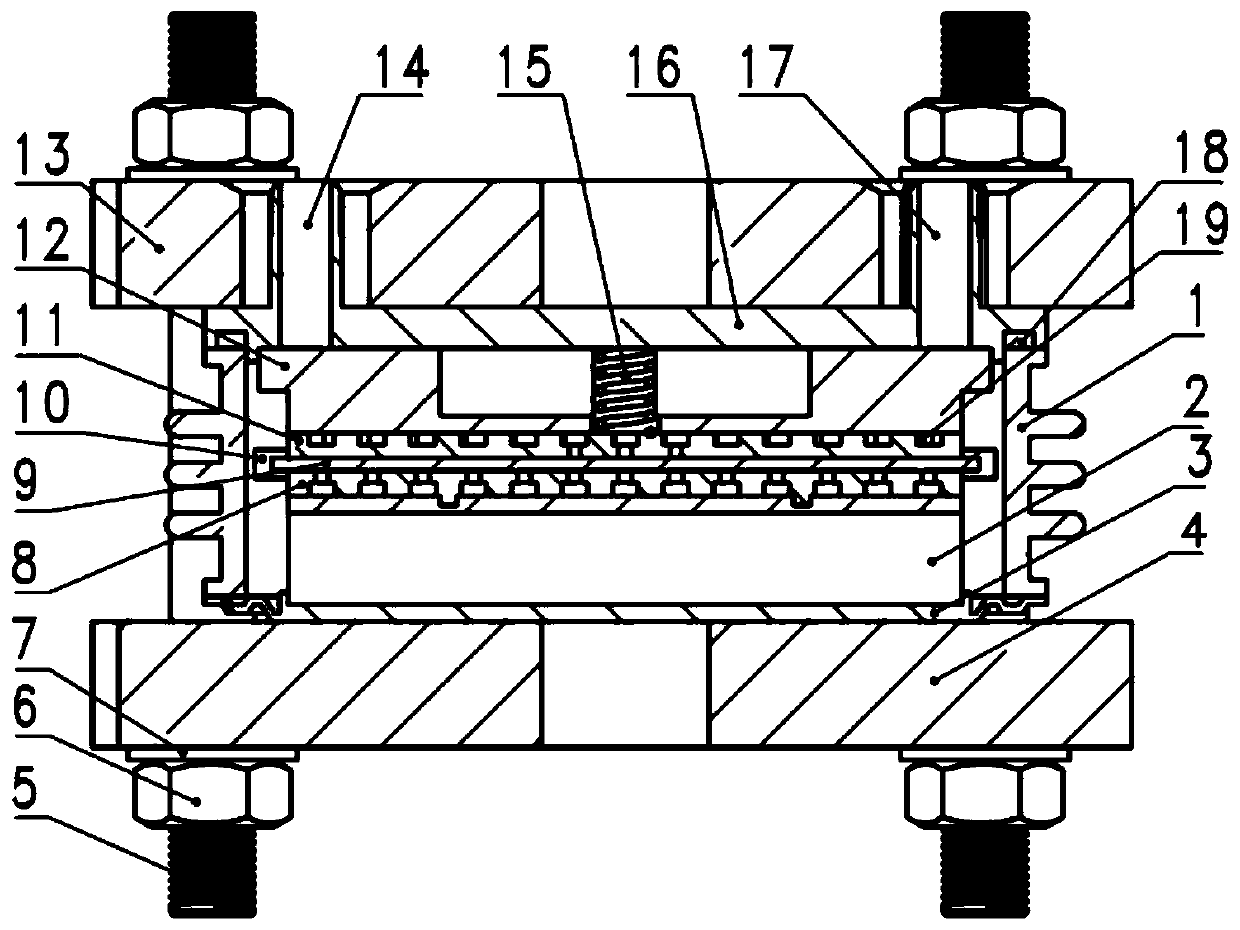

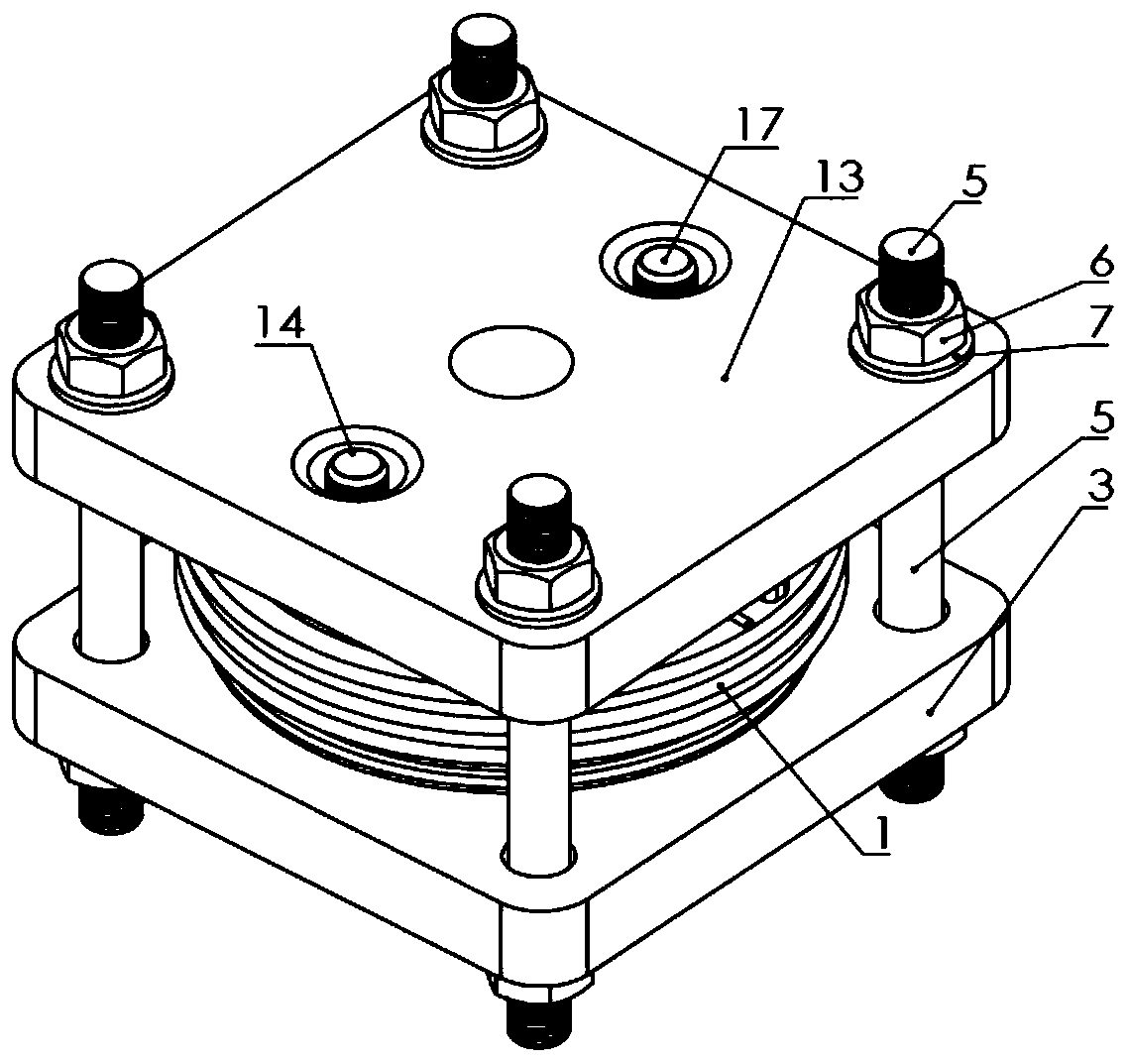

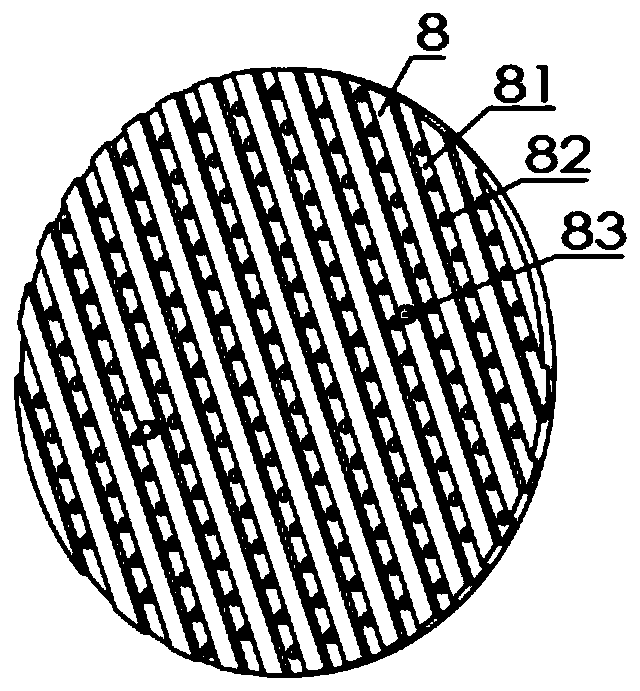

[0035] Such as figure 1 , 2 As shown, the high-voltage pulse thyristor switching device with heat management of the present invention includes a ceramic case 1 with a cylindrical inner cavity, a cathode base bottom plate 16 that is crimped and sealed on the upper end surface of the ceramic case 1 through a gasket 18, and a cathode base plate 16 that is sealed by welding The anode base bottom plate 3 sealed on the lower end surface of the ceramic shell 1;

[0036] It also includes an anode clamp 4 and a cathode clamp 13, the cathode clamp 13 is installed on the cathode base bottom plate 16, and the anode clamp 4 is installed under the anode base bottom plate 3; the cathode clamp 13 and the anode clamp 4 pass through the circumference Fasten and clamp the sealed cavity formed by the ceramic casing 1, the cathode base base plate 16 and the anode base base plate 3 to multiple groups of screw rods 5, nuts 6 and washers 7 that are uniformly arranged;

[0037] The anode heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com