Metal laser tube

A laser tube and metal technology, applied in the field of laser tubes, can solve the problems of easily broken customers, inconvenient recycling, loss, etc., and achieve the effect of firm overall structure, not easy to break, and good convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

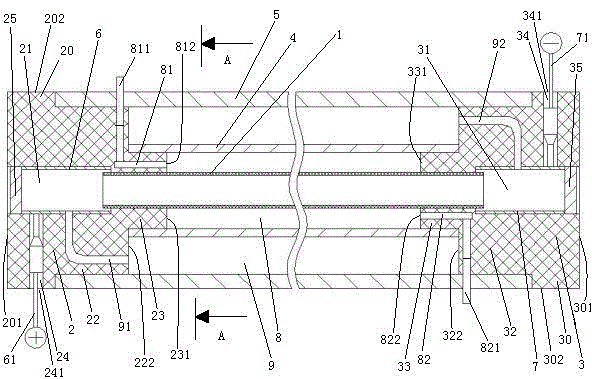

[0024] Embodiment one, see figure 1 , a metal laser tube, including a glass discharge tube 1, an anode end support seat 2, a cathode end support seat 3, a metal inner tube 4 and a metal outer tube 5.

[0025]The anode end support seat 2 is made of insulating material, such as ceramics. The anode end support seat 2 is provided with an anode end channel 21 . The anode end support base 2 is provided with an anode end support base 20 and a first protrusion 22 of the anode end support base located at one end of the anode end support base. The end surface of the first protruding head 22 of the anode end support seat is provided with a second protruding head 23 of the anode end support seat. The anode end channel 21 runs through the end surface 201 of the base of the anode end support seat and the end surface 231 of the second protrusion of the anode end support seat. The anode end support base 2 is provided with an anode wire lead-out hole 24 . The outer port 241 of the lead-out...

Embodiment 2

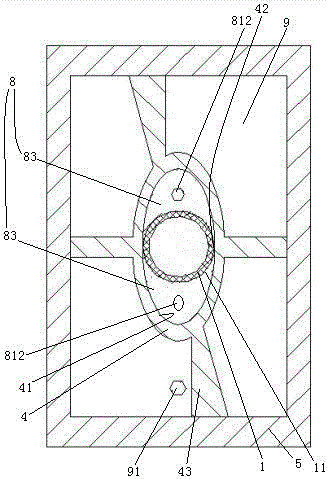

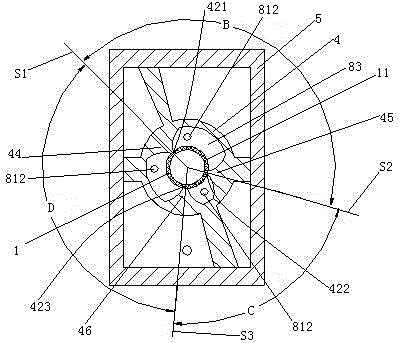

[0034] Embodiment two, see figure 2 , the difference with the first embodiment is: the inner tube 4 is circular. The inner surface of the inner tube 4 is provided with a first rib 44 , a second rib 45 and a third rib 46 . The first rib 44 and the outer surface 11 of the discharge tube are in line contact together to form a contact line 421 between the outer surface of the first discharge tube and the inner surface of the inner tube. The second rib 45 and the outer surface 11 of the discharge vessel are in line contact together to form a contact line 422 between the outer surface of the second discharge vessel and the inner surface of the inner tube. The third rib 46 is in line contact with the outer surface 11 of the discharge vessel to form a contact line 423 between the outer surface of the third discharge vessel and the inner surface of the inner tube. There are three cooling compartments 83 . The line of contact between the outer surface of the first discharge vessel a...

Embodiment 3

[0035] Embodiment three, see Figure 4 , the difference from Embodiment 1 is: the outer port 813 of the first refrigerant flow channel is located at the part where the outer surface of the anode terminal support seat is located outside the outer tube. The outer port 823 of the second refrigerant flow channel is located at the part where the outer surface of the cathode end support seat is located outside the outer tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com