Method for repairing noble metal target material

A repair method and precious metal technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of high cost of delamination and repair, and achieve the effect of simple process, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

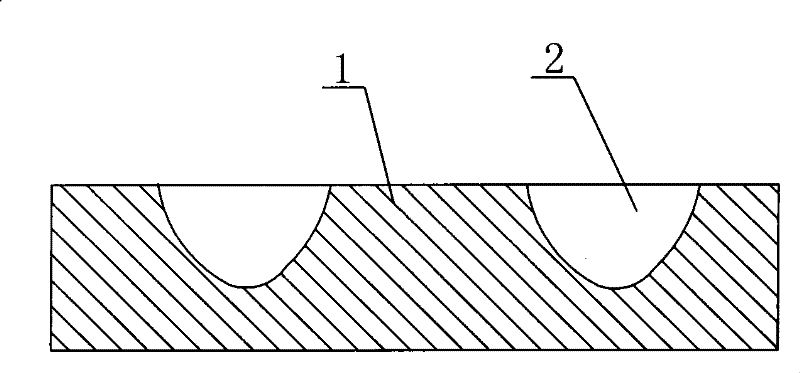

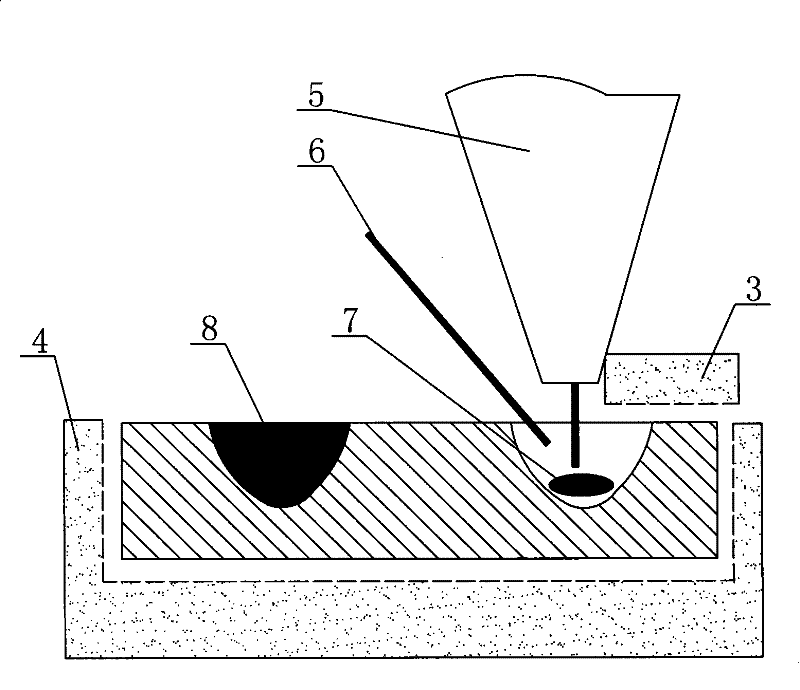

Image

Examples

Embodiment 1

[0023] The 2mm×2mm Pt wire was washed with alkali to degrease, rinsed repeatedly with water, and dried in the air. Under argon protection, the used Pt target was repaired by welding with a welding current of 85A. The welded target is filled and repaired, and the argon gas flow rate is 8L / min.

Embodiment 2

[0025] The Φ2.2mm Au wire was washed with alkali to degrease, rinsed repeatedly with clean water, and dried in the air. Under argon protection, the used Au target was repaired by welding with a welding current of 70A. The welded target is filled and repaired, and the argon gas flow rate is 25L / min.

Embodiment 3

[0027] The 1.2mm × 2mm Pd wire was washed with alkali to remove oil, rinsed repeatedly with clean water, and dried in the air. Under argon protection, the used Pd target was repaired by welding with a welding current of 78A. The welded target is filled and repaired, and the argon gas flow rate is 30L / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com