Acid and alkali corrosion resistant protection cover and application method thereof

A technology of protective cover and alkali corrosion, which is applied in the process of producing decorative surface effects, decorative art, gaseous chemical plating, etc., can solve the problem of destroying the structure of the device, and achieve the advantages of convenient use, simple structure, and easy disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

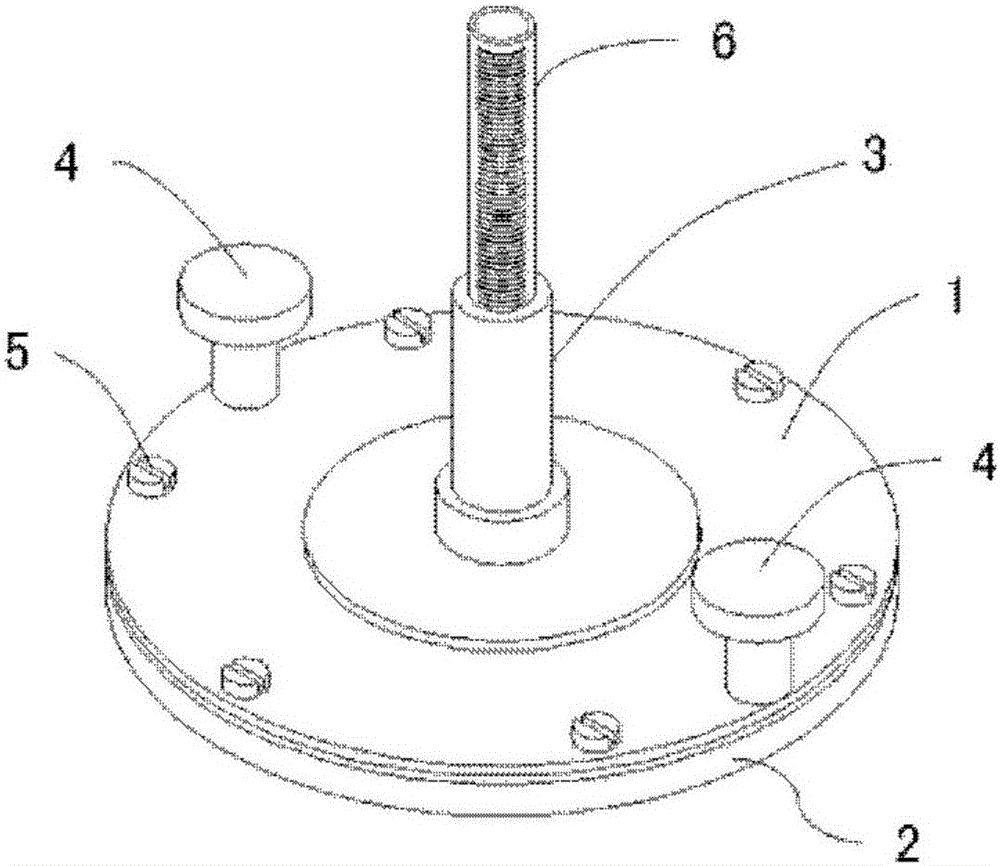

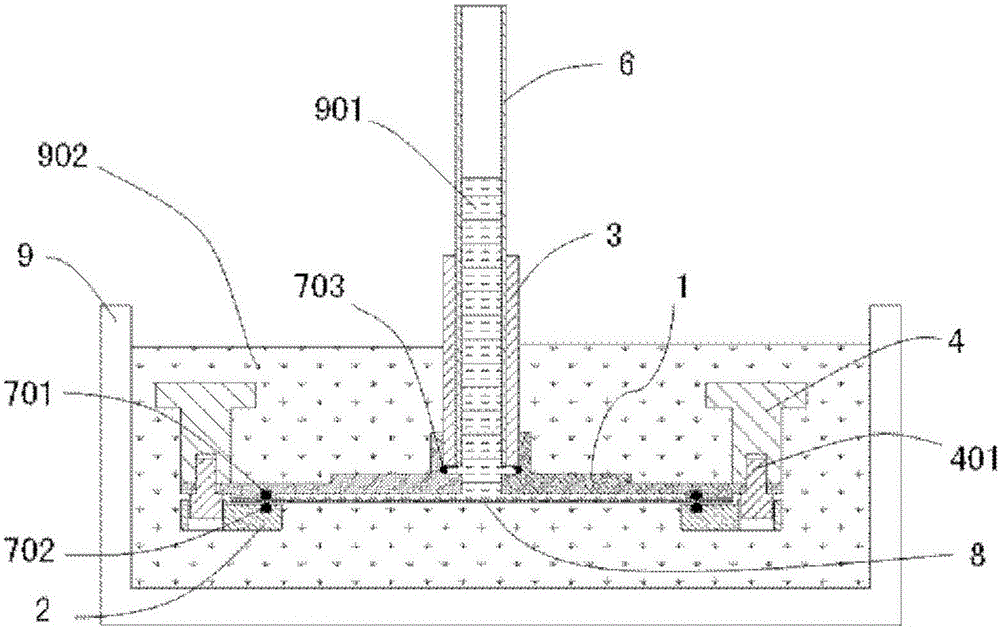

[0013] 1. Introduction to the structure of the protective cover

[0014] The protective cover designed by the present invention is mainly composed of the following parts: 1, top plate, 2, bottom plate, 3, transfer post, 4, handle, 5, fastening screw, 6, glass tube, 7, O-shaped rubber ring , 8, chip.

[0015] Refer to the attached figure 1 , 2 The function of each component is described in detail:

[0016] 1 in the figure is the top plate of the protective cover, and the material is made of materials that can withstand high temperature, strong acid resistance, and strong alkali resistance; there is a boss at the center of the front, and there is a through hole with a larger diameter with internal thread on the boss, which is consistent with 3 The external thread at one end matches, and there is a groove under the through hole, which is matched with 703, and there is a through hole with a smaller diameter downward; 1 Six (not limited to six) through holes are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com