Semiconductor device cleaning process and device

A technology for cleaning devices and semiconductors, used in cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of large consumption of acetone and IPA, long cleaning time, serious volatilization, etc., to remove residues Organic matter, good cleaning effect, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0033] The raw materials and equipment used in the following examples are commercially available unless otherwise specified.

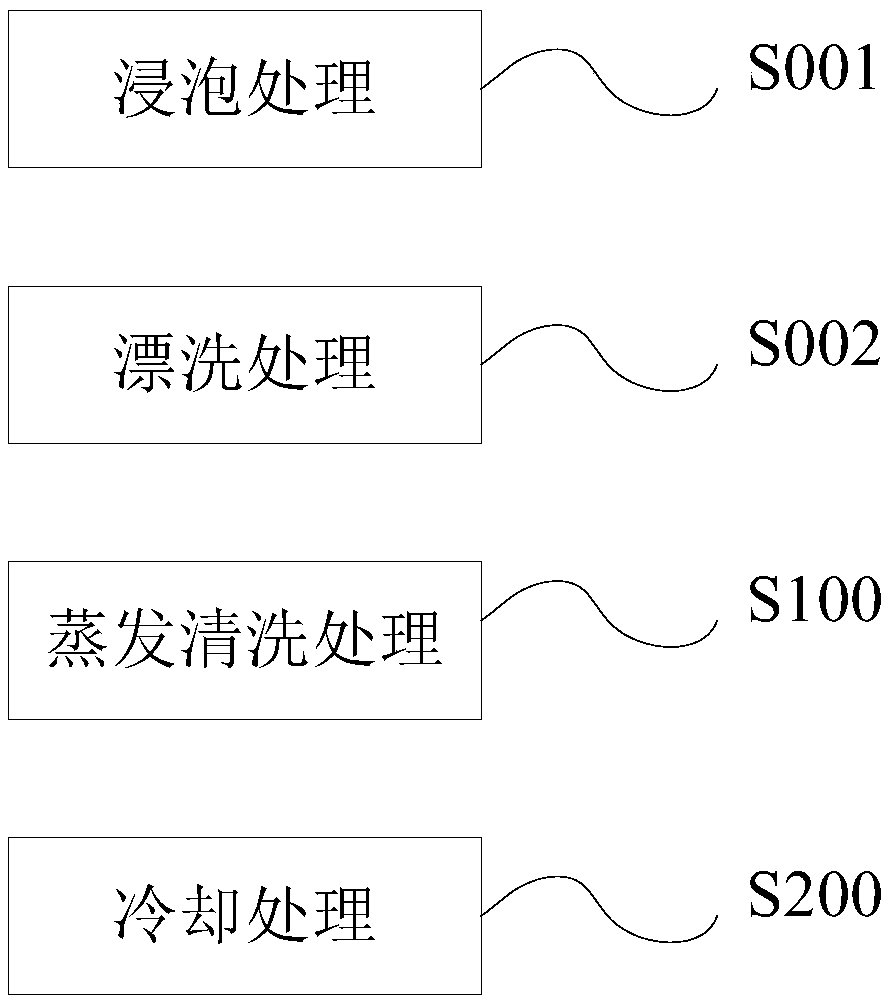

[0034] see figure 1 , the present invention provides a semiconductor device cleaning process, which comprises the following steps:

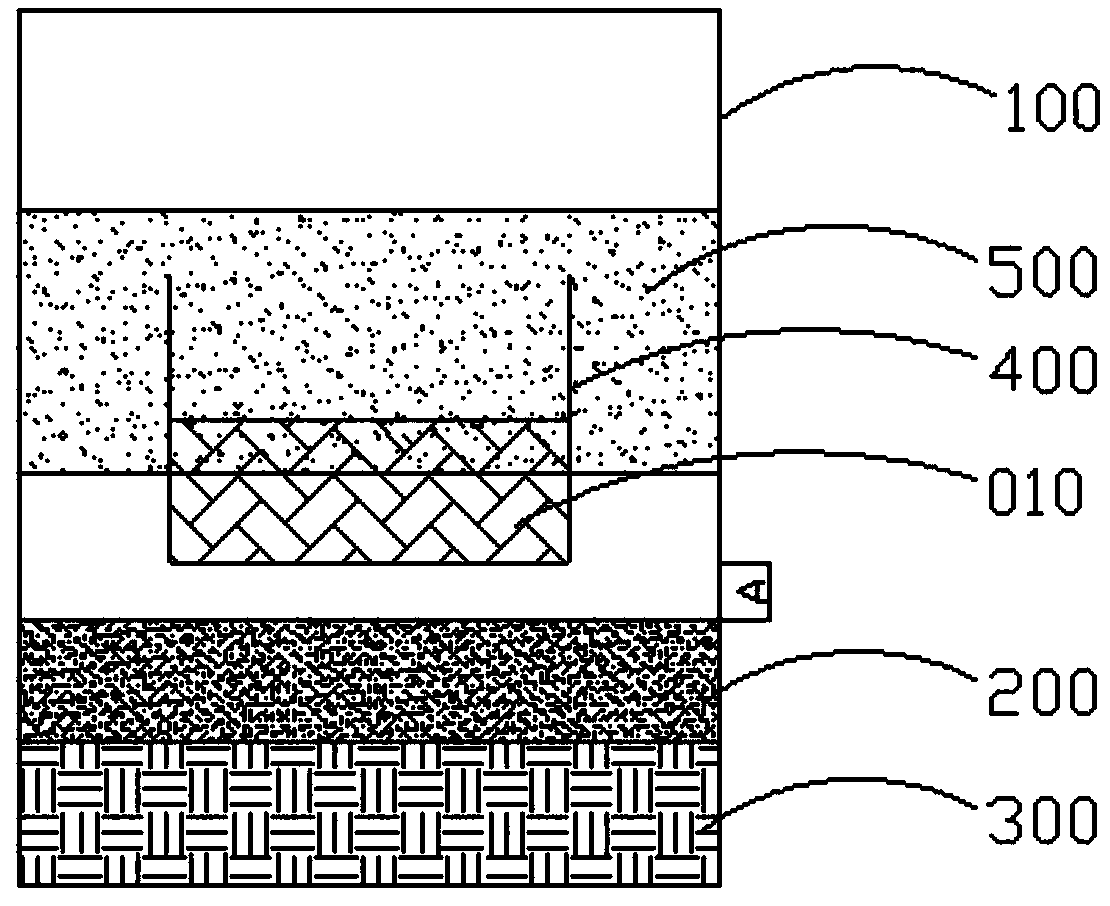

[0035] S100: evaporative cleaning step; use n-bromopropane vapor to clean the semi-conductor device to be treated; usually, the cleaning agent n-bromopropane solvent is heated to evaporate, and then the semiconductor device is placed in n-bromopropane vapor, at this time the n-bromopropane Propane vapor can completely cover the entire surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com