High-speed selective cesium adsorption resin material, method for preparing same and application thereof

A technology for adsorbing resins and polymer materials, applied in chemical instruments and methods, radioactive purification, other chemical processes, etc., to achieve the effects of strong controllability, good economic benefits, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Using crystalline cellulose microspheres (about 200 microns in average diameter, 76% crystallinity) as a polymer substrate, put 10 grams of the above materials into a PE bag containing nitrogen, and use an electron accelerator to perform electron beam radiation to make it Generate active free radicals that can be used for grafting reactions. Irradiation conditions: the irradiation voltage is 2MeV, the irradiation dose is 30kGy, and the dose rate is 10kGy / pass.

[0038] 2) The above-mentioned particles after irradiation are immediately put into an emulsion reaction system composed of 30wt% GMA+3wt% polyoxyethylene sorbitan monolaurate (Tween20)+67wt% water for graft polymerization. The emulsification reaction system of GMA monomer is continuously blown with nitrogen for 30 minutes before use to exhaust oxygen in the water. The graft polymerization reaction is carried out at 50°C, and the reaction is terminated after about 2 hours (the grafting rate of the substrate reac...

Embodiment 2

[0042] 1) Using polypropylene microsphere material (average diameter of 250 microns, crystallinity of 60%) as the polymer substrate, 10g of the above material and 1.5g of azobisisobutyronitrile, put in 30wt% 4-HBAGE+70wt% The graft polymerization reaction is carried out in an organic solvent (about 50g) composed of acetone. After the graft polymerization reaction is carried out at 60°C for 8 hours (the grafting rate of the substrate reaches about 80%), the reaction is terminated.

[0043] 2) The above-mentioned 4-HBAGE monomer grafted product, after washing and drying, put it into a 5wt% ammonium phosphotungstate suspension aqueous solution for epoxy ring-opening reaction, and shake the reaction at 80°C for 24 hours (ammonium phosphotungstate The introduction rate is about 15wt%), the cesium adsorption resin material is prepared after taking it out, washing and drying.

[0044] The adsorption resin material obtained by the above method has a diameter of about 300 microns, a densit...

Embodiment 3

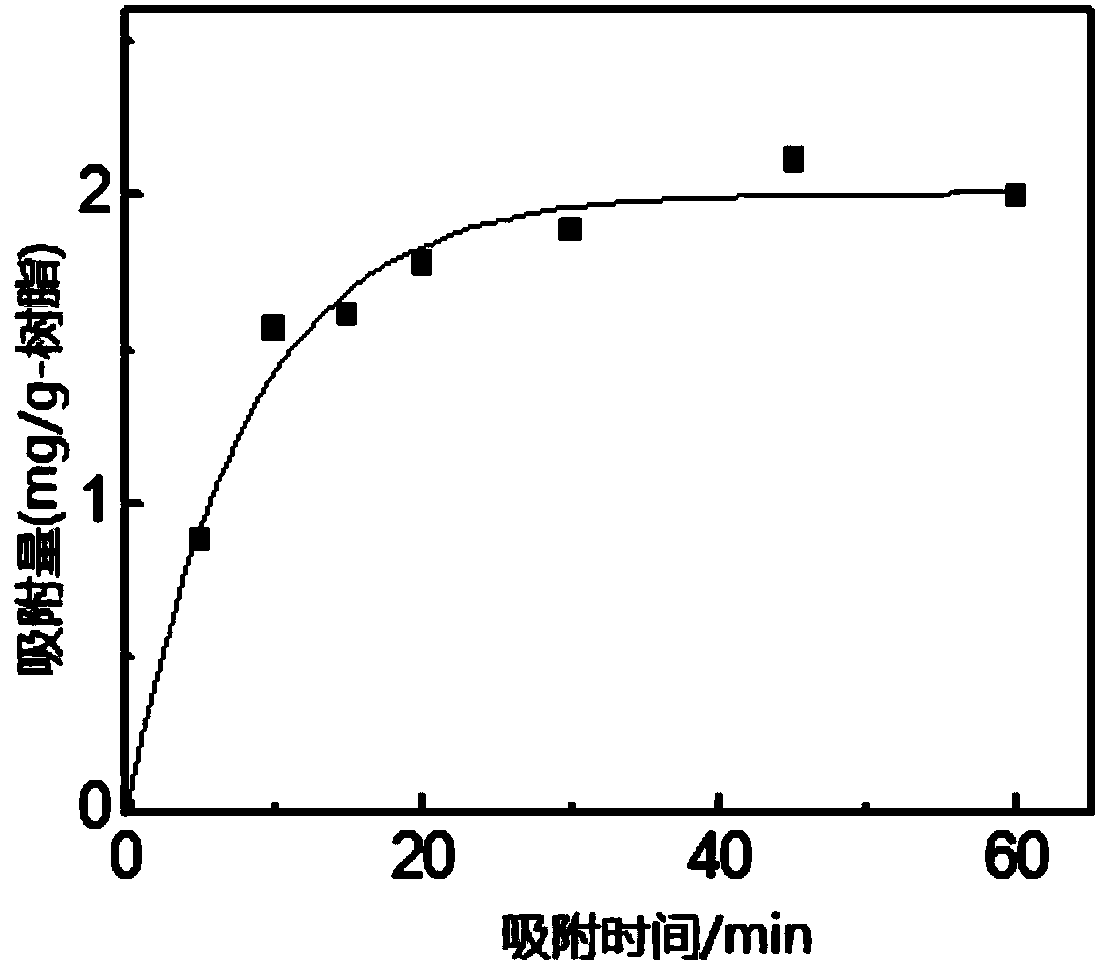

[0046] 1. Static adsorption test of Cs adsorption resin material

[0047] Weigh 0.1 g of the adsorbent material prepared in Example 1, and put it in 100 ml of an aqueous solution prepared with stable isotope 133Cs at room temperature to perform a static batch adsorption test. The Cs solution used in the adsorption test was prepared from 133Cs nitrate, with an initial concentration of 5 mg / L and pH 5.8. The above adsorption test was stirred at room temperature, the adsorption time was different from 5 min to 60 min, the supernatant was recovered, and the residual Cs concentration was analyzed by atomic absorption spectroscopy to calculate the adsorption amount.

[0048] From figure 2 We can see that the adsorption speed of the Cs adsorption resin obtained in the present invention is very fast, and the adsorption equilibrium is basically reached within 20 minutes, and it has the characteristics of high-speed adsorption of Cs.

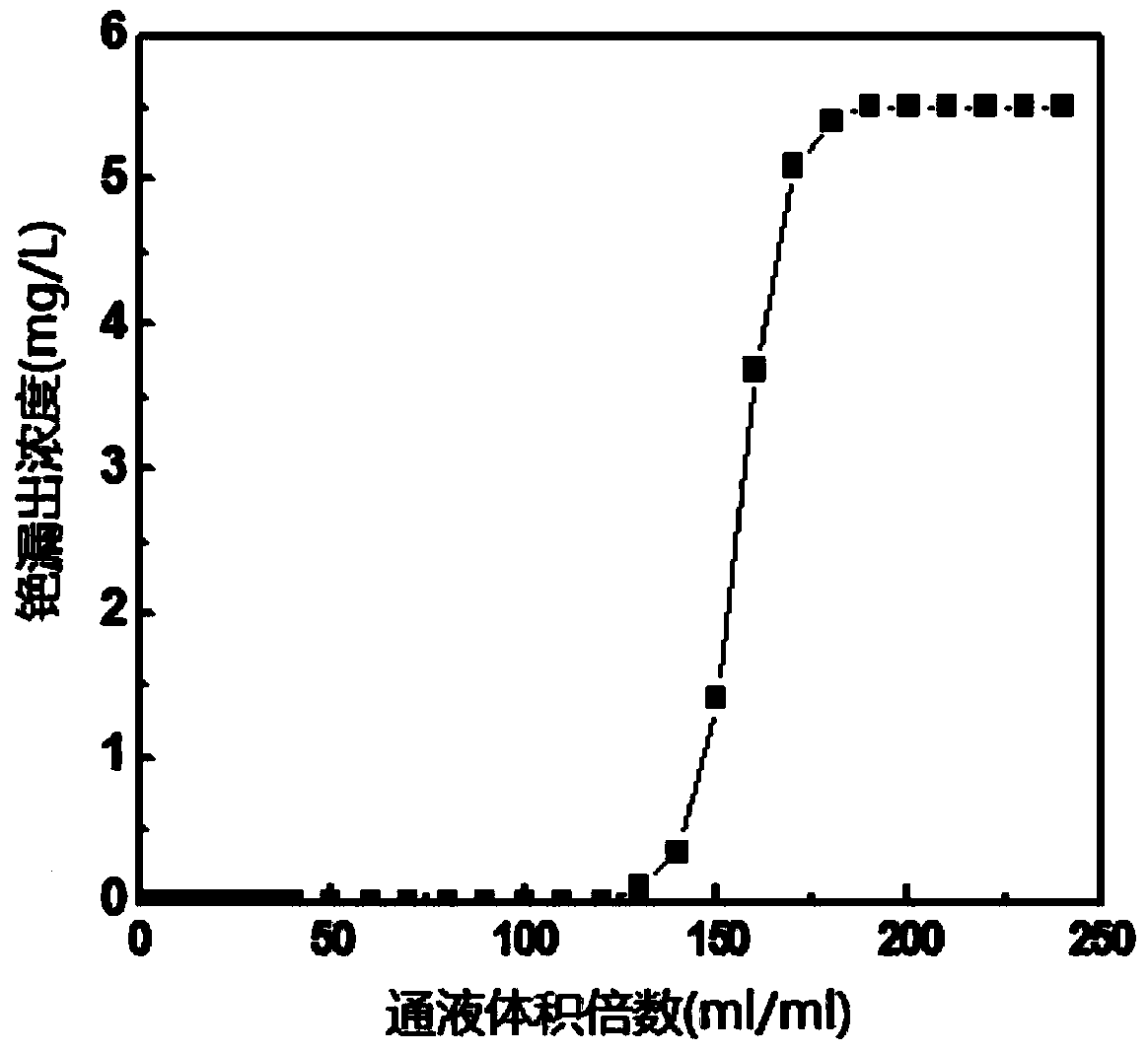

[0049] 2. Column pressure test of Cs adsorption resin ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com