Fuel-free device for oil-sludge segmented drying, pyrolysis, incineration and secondary combustion of garbage sludge

A technology for segmented drying and sludge, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of large floor space, high treatment costs, and difficulty in promotion, so as to reduce operating costs and increase the pyrolysis area. , the effect of self-combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

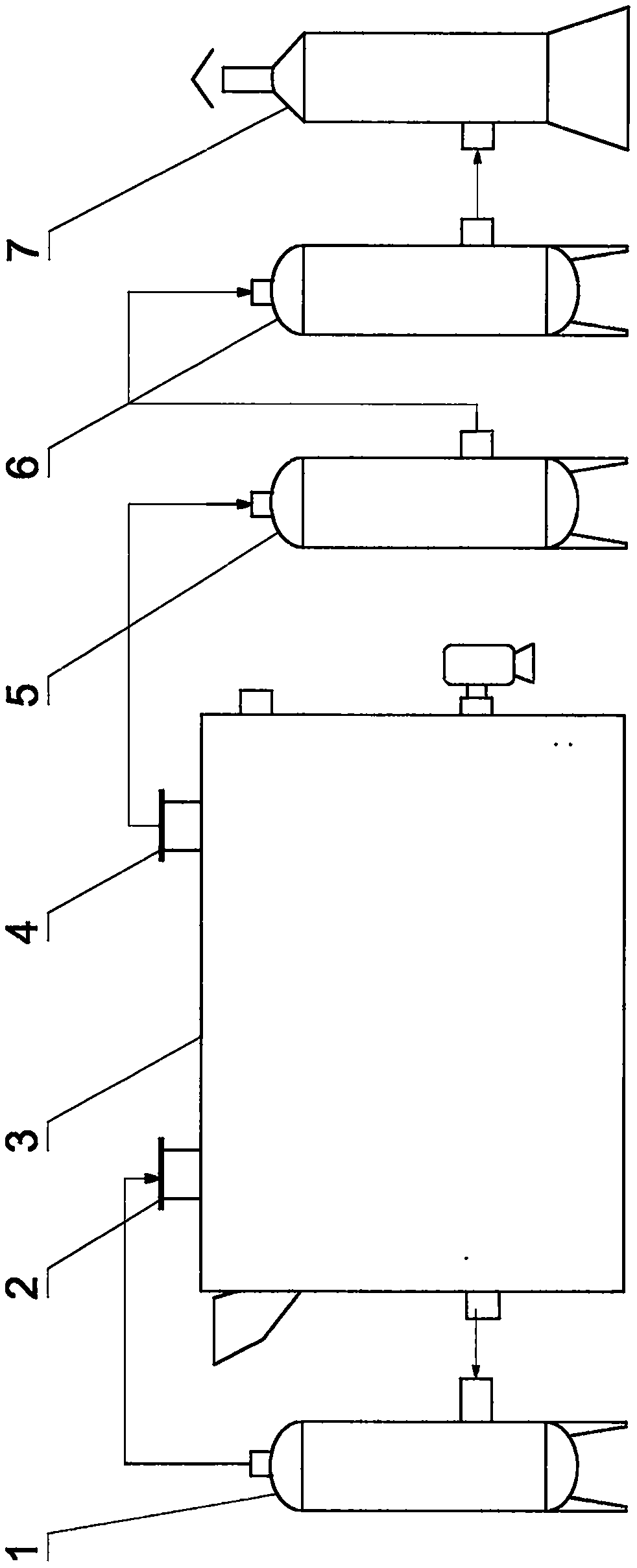

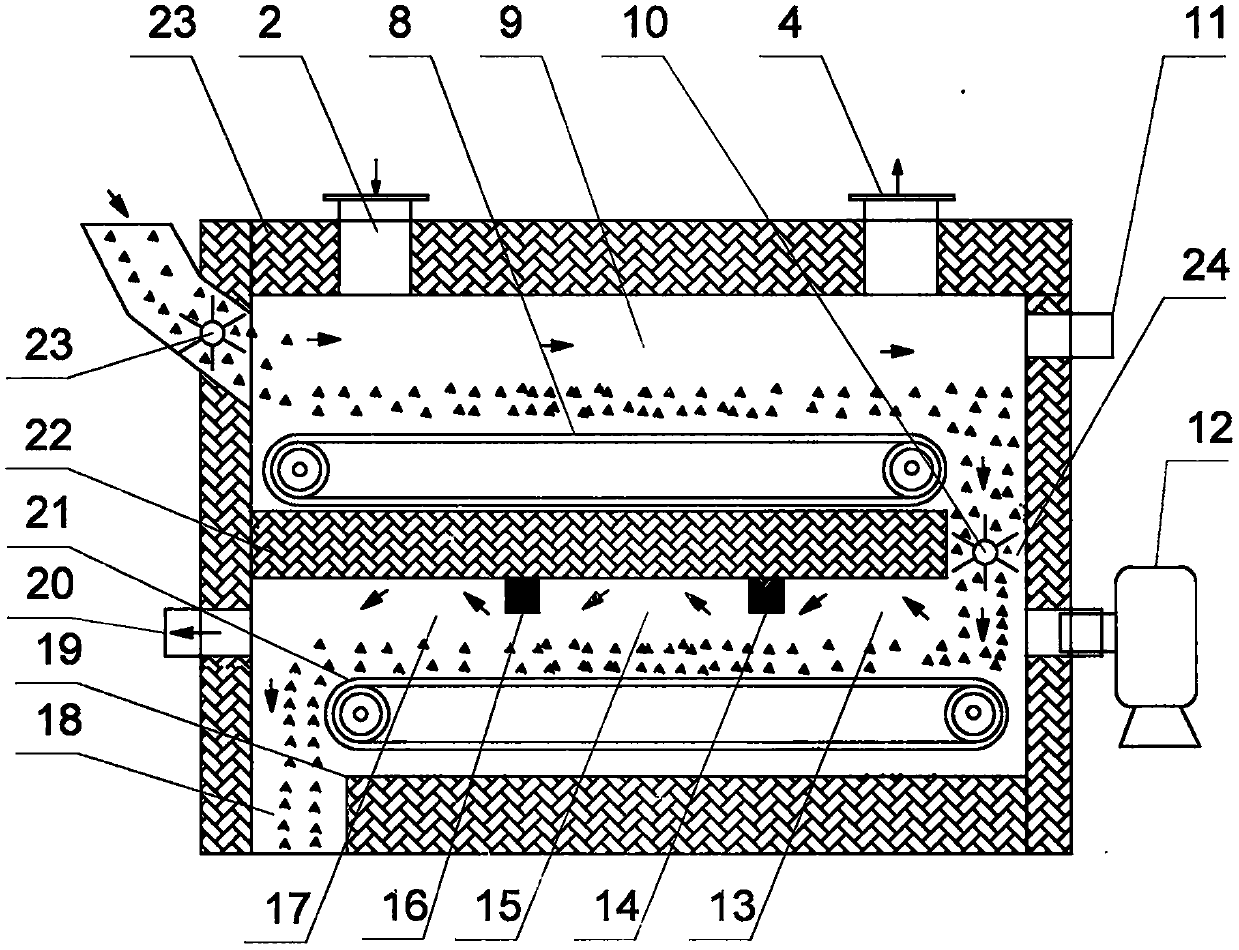

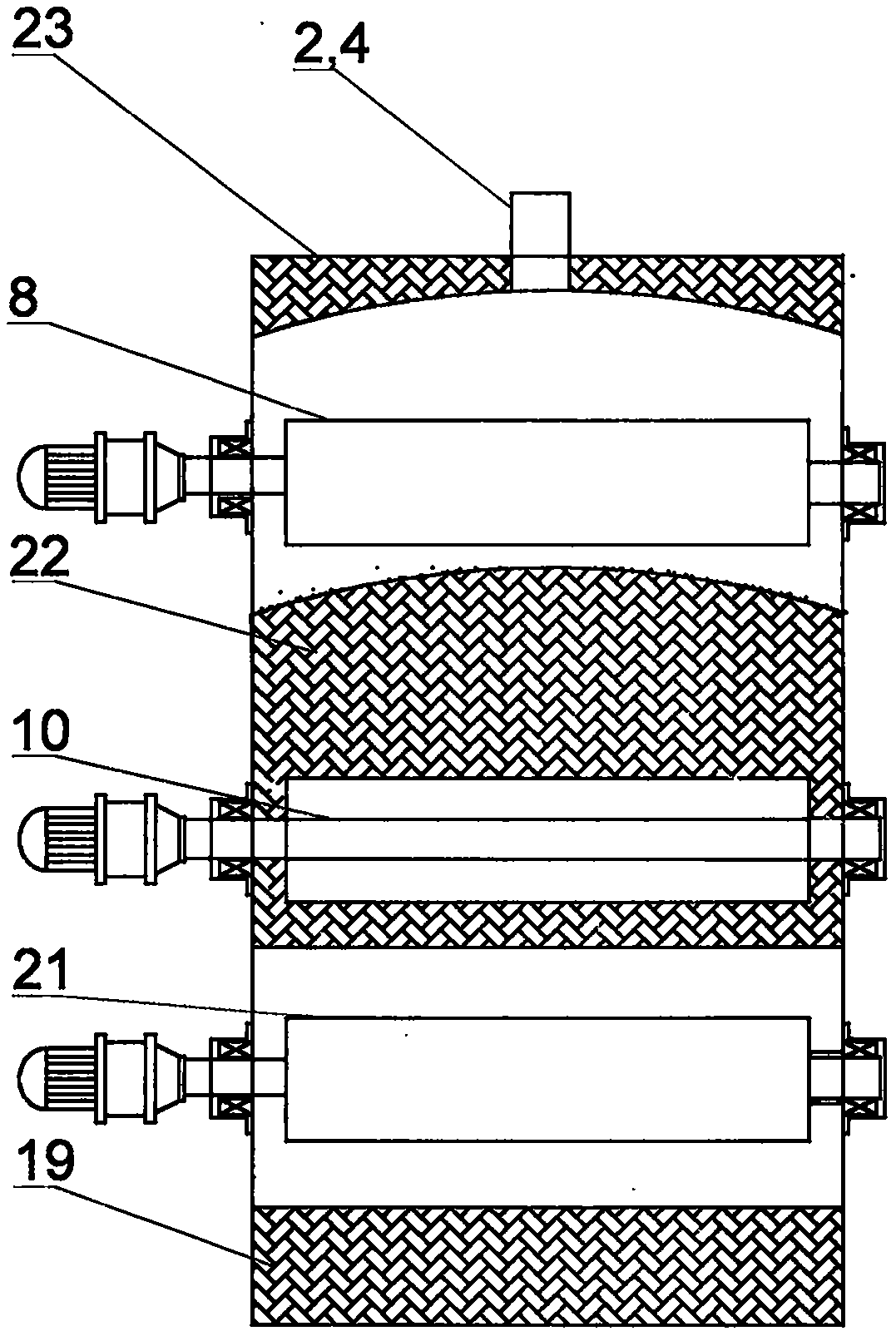

[0020] In the embodiment of the present invention, a garbage sludge sludge drying pyrolysis incineration and secondary combustion fuel-free device, the present invention consists of a quencher 1, a hot gas inlet 2, a multifunctional integrated furnace 3, an air outlet 4, and a denitrification device 5 , a desulfurizer 6, and an electrostatic precipitator 7, wherein the quench cooler 1 is connected and communicated with the hot gas inlet 2 through a connecting pipe; The other side of the upper part of the functional integrated furnace 3 is connected; the multifunctional integrated furnace 3 is connected and communicated with the denitrifier 5 through the connecting pipe, the denitrifier 5 is connected and communicated with the desulfurizer 6 through the connecting pipe, and the desulfurizer 6 is connected with the electrostatic precipitator through the connecting pipe The device 7 is connected and communicated, and the multifunctional integrated furnace 3 is connected and commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com