A kind of chemical industry sewage environmental protection treatment device

An environmental protection treatment and industrial technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that cannot meet the environmental protection production needs of chemical enterprises, effectively filter chemical waste, and reduce waste water. Dealing with efficiency and other issues, to achieve the effect of environmental protection, easy cleaning and replacement, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

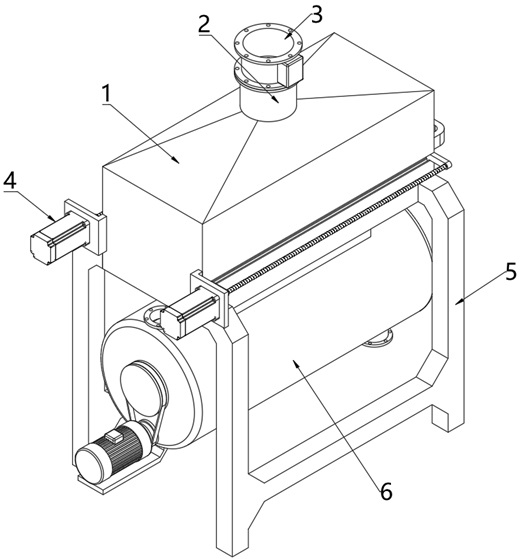

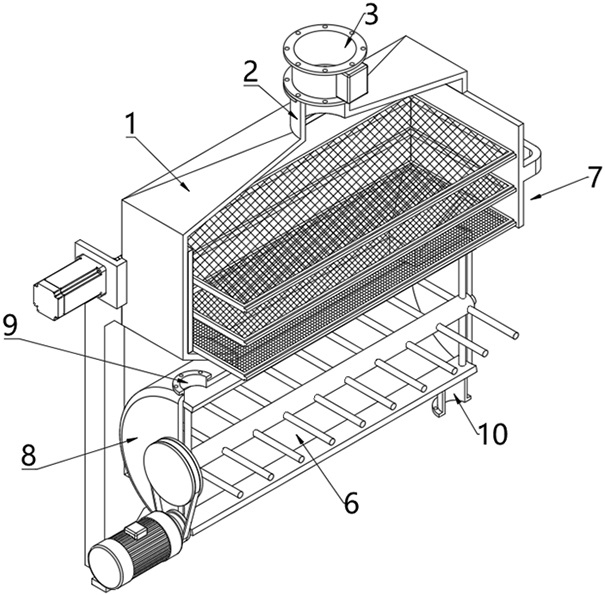

[0030] like figure 2 and Figure 7 As shown, in this embodiment, in order to achieve efficient filtration and treatment of chemical wastewater, the top surface of the treatment tank 1 is fixedly installed with a through water inlet pipe 2, and the top surface of the water inlet pipe 2 is fixedly connected with a flow valve through a flange. 3. The support frame 5 is fixedly connected to the left and right side walls of the processing box 1, the rear end wall of the processing box 1 is provided with a slag outlet 11, the outer side wall of the baffle plate 28 is fixedly installed with a handle 29, and the baffle plate 28 Three filter frames 30 are fixed vertically on the inner side wall of the filter frame 30 , the installation clips 31 corresponding to the installation slot 20 are fixedly installed on the two side walls of the filter frame 30 , and the upper filter frame 30 is fixedly installed in the frame. A filter screen 32, a second filter screen 33 is fixedly installed ...

Embodiment 2

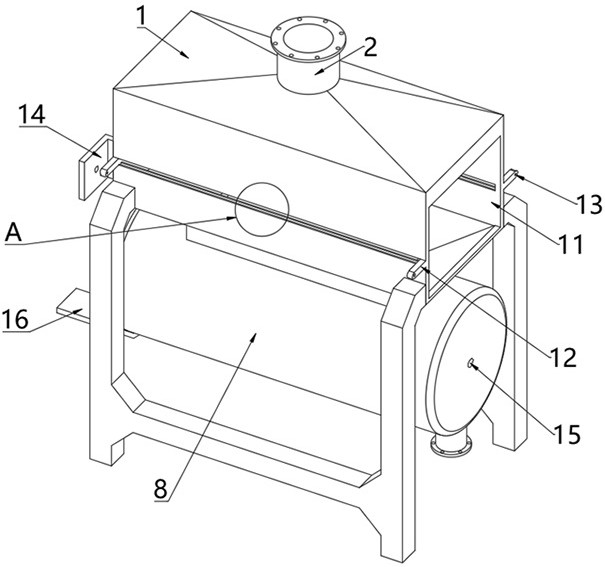

[0032] like Figure 3-Figure 5 As shown, in this embodiment, in order to facilitate the cleaning of the waste residue filtered out by the filter mechanism 7, the left and right side walls of the treatment box 1 are respectively provided with transverse openings 17, and the upper and lower ends of the inner wall of the transverse opening 17 are respectively A sliding groove 18 is provided, and side plates 12 are fixed and installed on both sides of the transverse opening 17 and are located on the outer wall of the processing box 1, and a first rotating hole 13 is opened on the side wall of the side plate 12. The front end of the processing box 1 A first mounting plate 14 is also fixedly installed on both sides of the wall, and a first rotating rod 26 is fixedly installed at the front and rear ends of the threaded rod 25, and the first rotating rod 26 is inserted and installed in the first rotating hole 13, and the first driving The motor 27 is fixedly installed on the front end...

Embodiment 3

[0034] like image 3 and Figure 7 As shown, in this embodiment, in order to chemically treat the waste water and ensure that the waste water and chemicals are mixed evenly, the stirring tank 8 is fixedly installed on the bottom surface of the processing tank 1 and communicates with the processing tank 1. The front and rear of the stirring shaft 35 A second rotating rod 36 is fixedly installed at both ends, and the second rotating rod 36 is inserted and installed in the second rotating hole 15, and a large pulley 37 is fixedly installed on the end wall of the second rotating rod 36 installed at the front end of the stirring shaft 35. The second mounting plate 16 is fixedly installed on the front end of the bottom surface of the stirring tank 8 , the second driving motor 38 is fixedly mounted on the top surface of the second mounting plate 16 by bolts, and the output end of the second driving motor 38 is fixedly mounted with a small pulley 39, and the second drive motor 38 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com