Method and device for improving surface properties of copper alloy

A technology of surface properties and copper alloys, which is applied in the field of improving the surface properties of copper alloys and copper contract surface treatment, can solve the problems that copper alloy surface treatment technology cannot fundamentally improve copper alloys, etc., and achieve surface quality protection, simple process methods, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

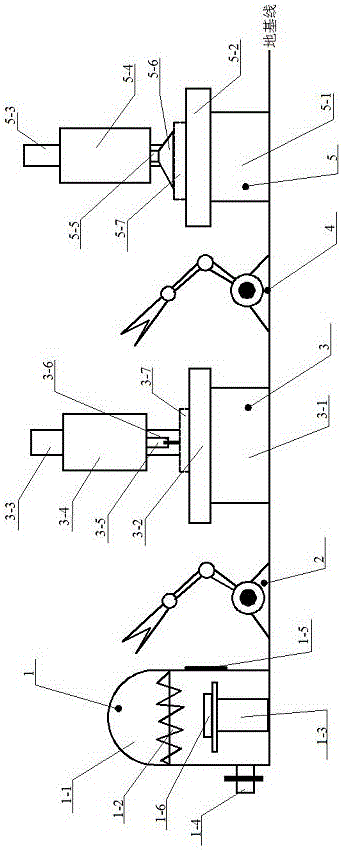

[0031] Such as Figure 1-3 shown.

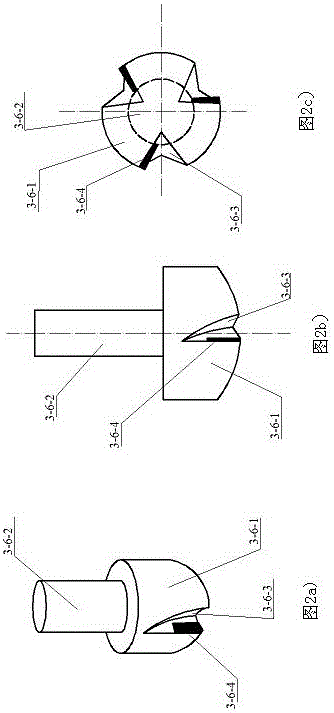

[0032] A method for improving the surface properties of copper alloys. First, place workpieces 1-6 on the workbench 1-3 in the heating mechanism 1, close the furnace door 1-5, and then vacuumize the heating chamber at 1-4. 1-1 Vacuumize, the vacuum degree is 95~98%, and then connect the heating wire 1-2 to heat the workpiece 1-6. When the temperature measuring instrument in the heating chamber shows that the temperature reaches 400~500°C, stop heating and open the furnace door 1-5, the workpiece 1-6 is placed on the 3-7 position of the workbench 3-2 of the surface strengthening mechanism 3 by the manipulator 2, and then the switch of the surface strengthening mechanism 3 is turned on, and the head of the bed installed on the pillar 3-3 3-4 drives the clamping part 3-5 to rotate, and the bed head 3-4 can move up and down with the pillar 3-3 to adjust the proper position, and the stirring head 3-6 installed on the clamping part 3-5 also rotates...

Embodiment 2

[0034] Such as Figure 1-3 shown.

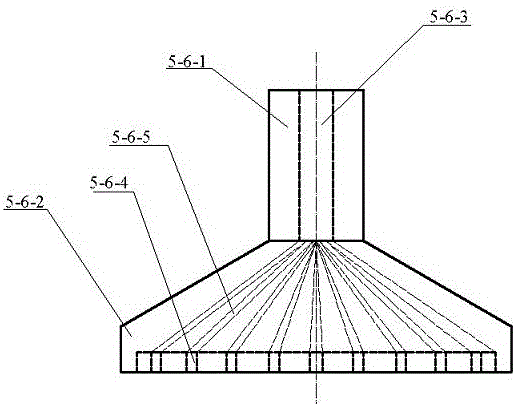

[0035] A device for improving the surface properties of copper alloys, which is mainly composed of a heating mechanism 1, a first manipulator 2, a surface strengthening mechanism 3, a second manipulator 4 and a surface grinding mechanism 5, such as figure 1 As shown; the first manipulator 2 is located between the heating mechanism 1 and the surface strengthening mechanism 3, and is used to take out the workpiece heated by the heating mechanism 1 and send it into the surface strengthening mechanism 3 for surface strengthening under the thermal state; the second The manipulator 4 is located between the surface strengthening mechanism 3 and the surface grinding mechanism 5, and is used to send the workpiece after surface strengthening of the surface strengthening mechanism 3 into the surface grinding mechanism 5 for final surface treatment; the heating mechanism 1 is mainly composed of a heating chamber 1- 1. The heating wire 1-2 and the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com