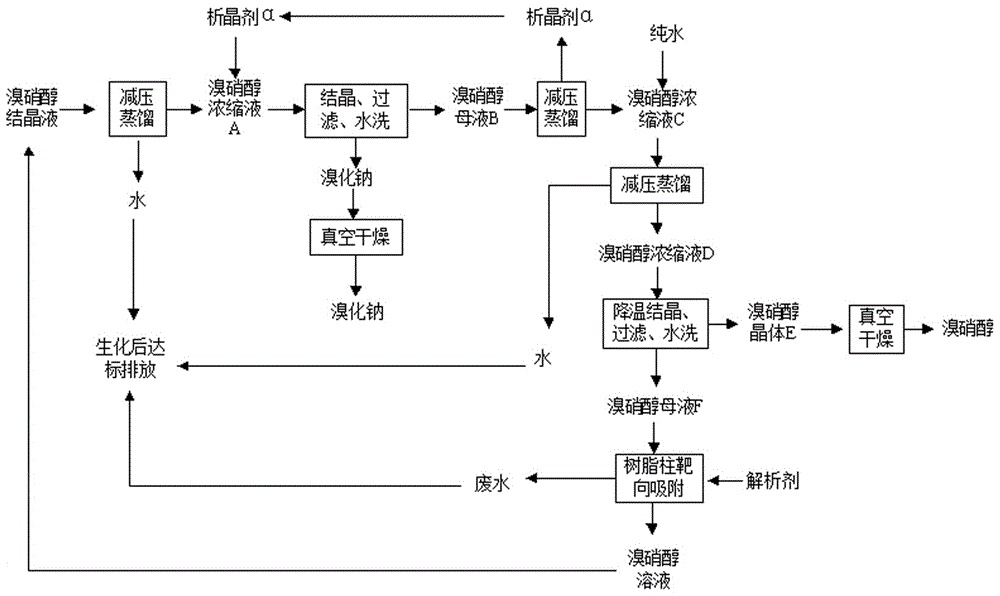

Bronopol refining process

A technology of bronopol and process, which is applied in the field of bronopol refining process and chemical product refining process, can solve the problems of low product yield and waste water pollution, and achieve the effects of content reduction, environmental protection pressure and waste water treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 A bronopol refining process comprises the following steps:

[0021] (1) Using conventional methods, nitromethane, formaldehyde and liquid bromine were used to carry out hydroxyalkylation and bromination reactions to obtain 1000L bronopol crude product crystallization liquid, wherein the content of bronopol was 232.5kg / L;

[0022] (2) Distill the 1000L bronopol crude crystallization solution obtained in step (1) under reduced pressure at a temperature of 58°C to obtain bronopol concentrate A, and the distilled water is discharged after biochemical treatment up to standard;

[0023] (3) Add crystallization agent acetonitrile to bronopol concentrated solution A obtained in step (2) for crystallization, keep for 25 minutes, then cool down to 3°C and continue stirring for 55 minutes; then filter and wash to obtain sodium bromide crystals and Contain the bronopol mother liquor B of crystallization agent acetonitrile, sodium bromide crystal is vacuum-dried at 40 D...

Embodiment 2

[0030] Embodiment 2 A bronopol refining process comprises the following steps:

[0031] (1) Using conventional methods , Utilize nitromethane, formaldehyde and liquid bromine to carry out hydroxyalkylation reaction and bromination reaction to obtain 1000L bronopol crude product crystallization liquid, wherein bronopol content is 240kg / L;

[0032] (2) Distill the 1000L bronopol crude product obtained in step (1) under reduced pressure at a temperature of 65°C to obtain bronopol concentrated solution A, and the distilled water is discharged after biochemical treatment up to standard;

[0033] (3) Add crystallization agent ethanol to the bronopol concentrated solution A obtained in step (2) to crystallize, keep for 26 minutes, then cool down to 2°C and continue stirring for 60 minutes; then filter and wash to obtain sodium bromide crystals and Containing the bronopol mother liquor B of crystallization agent ethanol, the sodium bromide crystal is vacuum-dried at 41 DEG C to obtai...

Embodiment 3

[0040] Embodiment 3 A bronopol refining process comprises the following steps:

[0041] (1) Using conventional methods, use nitromethane, formaldehyde and liquid bromine to carry out hydroxyalkylation and bromination reactions to obtain 1000L bronopol crystallization liquid, wherein the content of bronopol is 235kg / L;

[0042] (2) Distill the 1000L bronopol crude product obtained in step (1) under reduced pressure at a temperature of 60°C to obtain bronopol concentrated solution A, and the distilled water is discharged after biochemical treatment up to standard;

[0043] (3) Add 235L crystallization agent methyl formate to the bronopol concentrated solution A obtained in step (2) for crystallization, stir while crystallizing, keep for 30min, then cool down to 1°C and keep stirring for 65min; then filter, After washing, sodium bromide crystals and bronopol mother liquor B containing crystallizer methyl formate were obtained, and the sodium bromide crystals were vacuum-dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com