Upgrading process of strips

A processing technology and a technology for sheet cigarettes, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problem of not being able to meet the needs of high-end cigarette materials well, and achieve the effects of improving the use value, enhancing the use value, and being convenient for classification and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

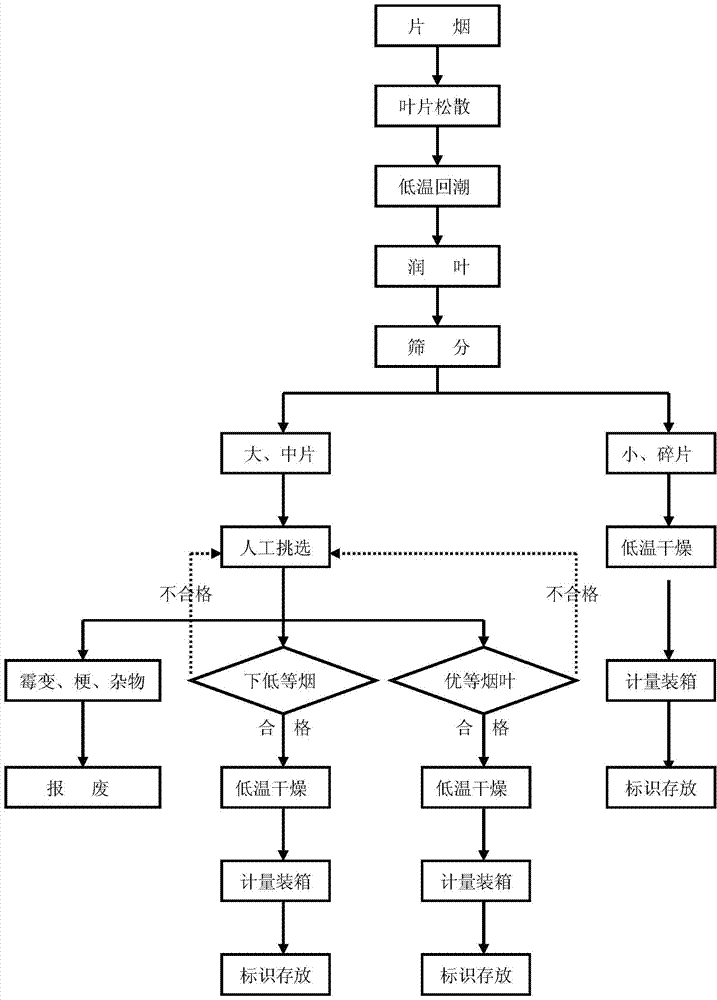

[0023] A process for improving the quality of sheet tobacco:

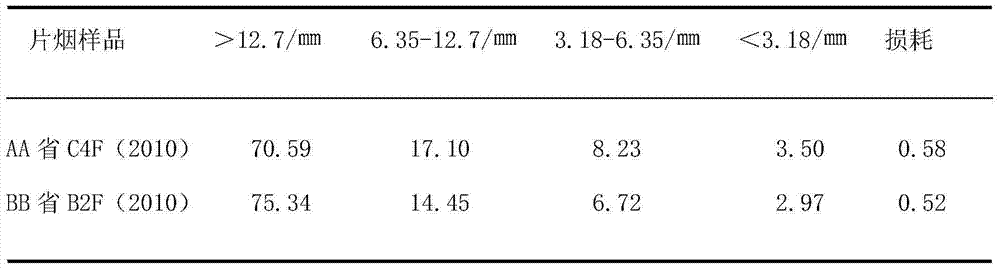

[0024] 1. Material preparation: Transport the raw materials (finished box cigarettes) of AA Province C4F (2010) and BB Province B2F (2010) to be upgraded to the production workshop according to the production requirements, and check the place of origin, grade, year of production, and number of pieces (or Weight), etc., make a record.

[0025] 2. Loosening: before regaining moisture, the layers are loosened according to the hardening of the raw materials, and then the layers are discharged to the smoke basket, and the surface is covered with sackcloth. The cigarettes in the cigarette basket should be stacked neatly and must not touch the inner wall of the humidifier to prevent the wear of the tank and the generation of water-stained smoke.

[0026] 3. Vacuum dampening and leaf moistening: After vacuum dampening and leaf moistening, the temperature of the tobacco sheet is not higher than 50°C, and the moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com