Processing technology of solid wood furniture board

A processing technology and board technology, which is applied in the field of processing technology of solid wood furniture boards, can solve problems such as affecting environmental sanitation and adverse environmental protection, and achieve the effects of ensuring environmental sanitation, improving efficiency and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

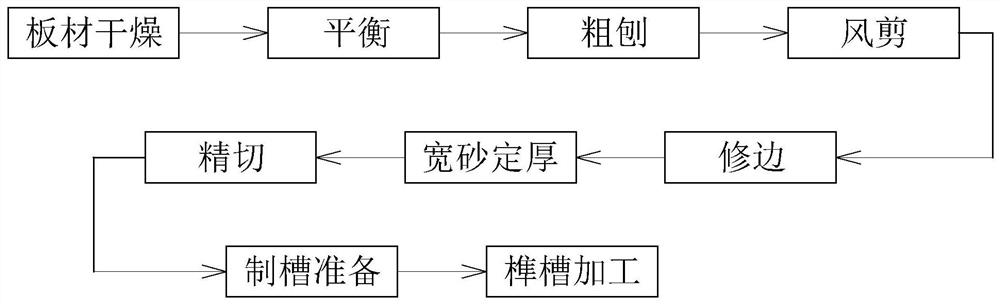

[0052] refer to figure 2 , is the processing technology of a kind of solid wood furniture board material disclosed by the present invention, comprises the following steps:

[0053] Step 1, plate drying: dry the plate and control the moisture content of the plate at 12.5%-15.5%;

[0054] Step 2. Balance: Let the dried board stand for 3-7 days;

[0055] Step 3, rough planing: the thickness of the board obtained in step 2 is determined to form a wool board;

[0056] Step 4. Wind shearing: trim the length of the wool board to the actual required length and lengthen it by 10-20mm;

[0057] Step 5, trimming: remove the burrs and burrs on the surface of the wool board;

[0058] Step 6. Thickness determination of wide sand: according to the requirements, coarse sand and polished sand are applied to the wool board to form a flat board. The thickness of the primary sand for coarse sand is 0.2mm, and the thickness of primary sand for polished sand is 0.1mm;

[0059] Step 7. Fine cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com