Dustproof cutting machine for polypropylene (PP) slices

A dust-proof and cutting machine technology, which is applied in metal processing and other directions, can solve the problems that PP sheets cannot be punched and cut at the same time, and it is easy to affect the health of workers in the working environment, so as to improve processing efficiency and ensure environmental protection. Hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

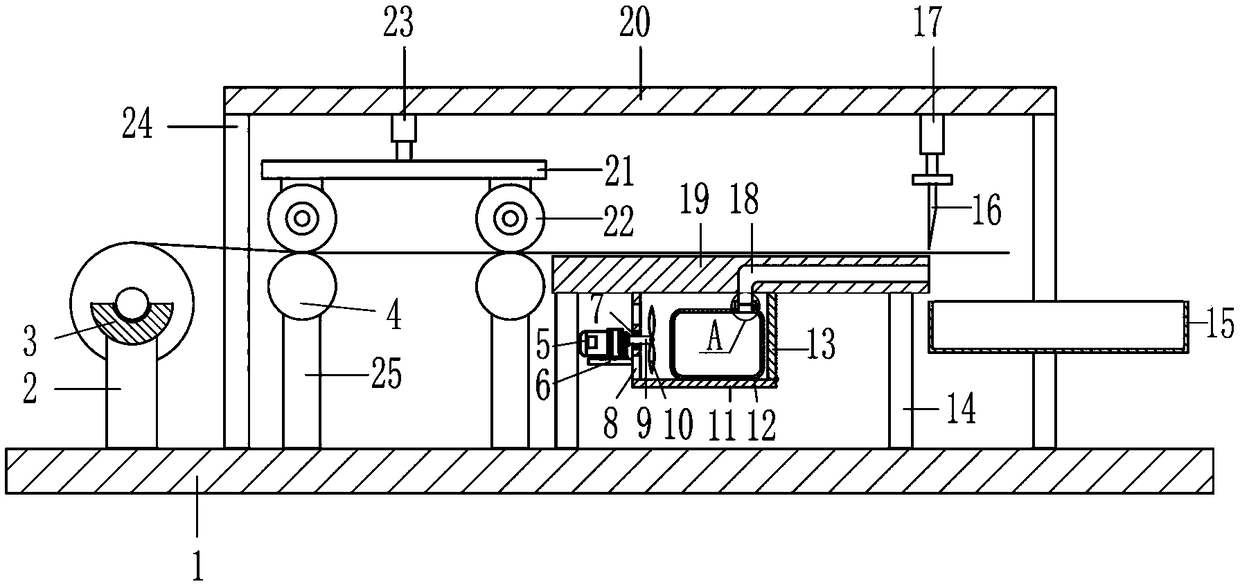

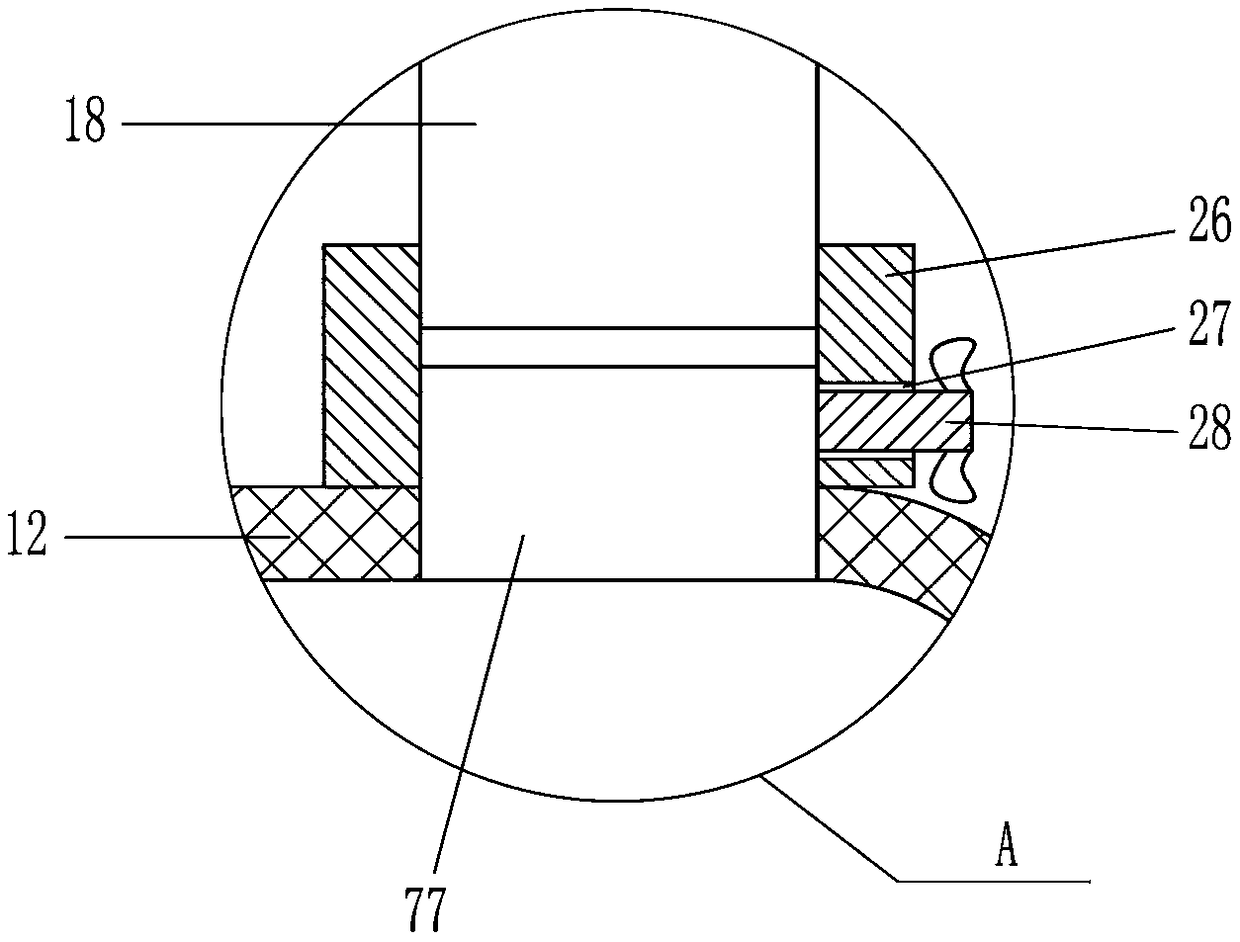

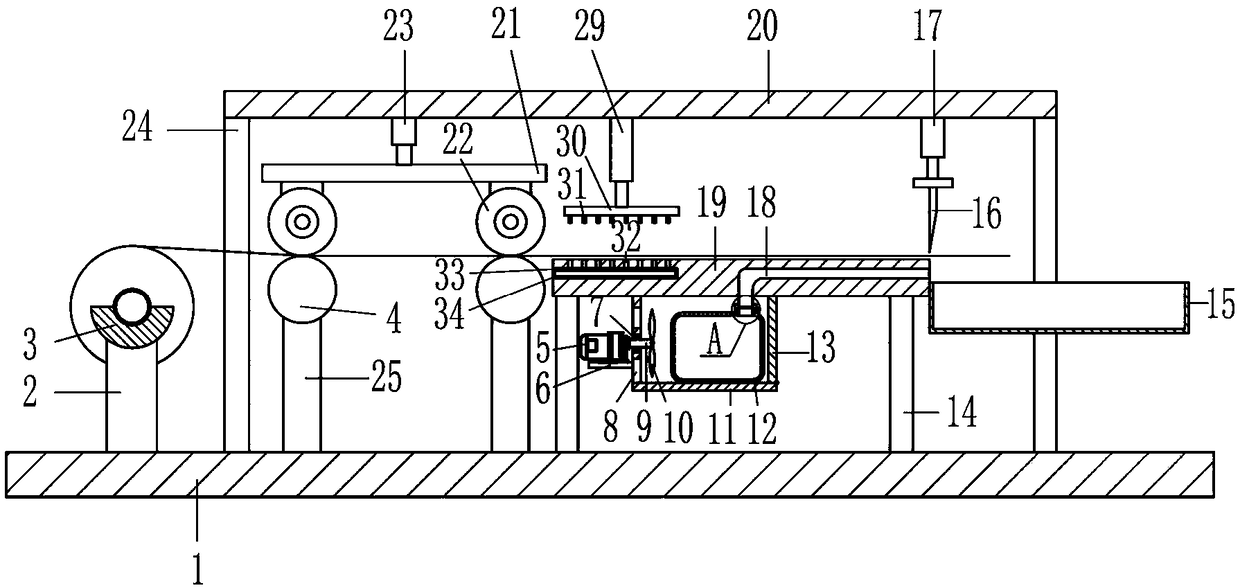

[0030] A PP sheet dust-proof cutting machine, such as Figure 1-8 As shown, it includes a first mounting plate 1, a first support base 2, a first arc plate 3, a driven roller 4, a motor 5, a second mounting plate 6, a bearing seat 7, a rotating shaft 9, a fan blade 10, a dust removal Frame 11, dust filter bag 12, baffle plate 13, second support seat 14, collection frame 15, cutting blade 16, first electric push rod 17, exhaust pipe 18, cutting table 19, third mounting plate 20, first lift Plate 21, driving roller 22, second electric push rod 23, support frame 24, dust cover 26, feed pipe 77, first butterfly bolt 28 and third support seat 25; the first arc plate 3 passes through the first The support base 2 is affixed to the top of the first installation plate 1, the cutting table 19 is affixed to the top of the first installation plate 1 through the second support base 14, and the driven roller 4 is affixed to the first installation plate 1 through the third support base 25 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com