Preparation method of metal surface copper-nickel alloy

A metal surface, copper-nickel alloy technology, applied in the field of metal surface anti-corrosion, can solve the problems of complex equipment, high temperature, film holes, etc., and achieve the effects of simple preparation method, excellent corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

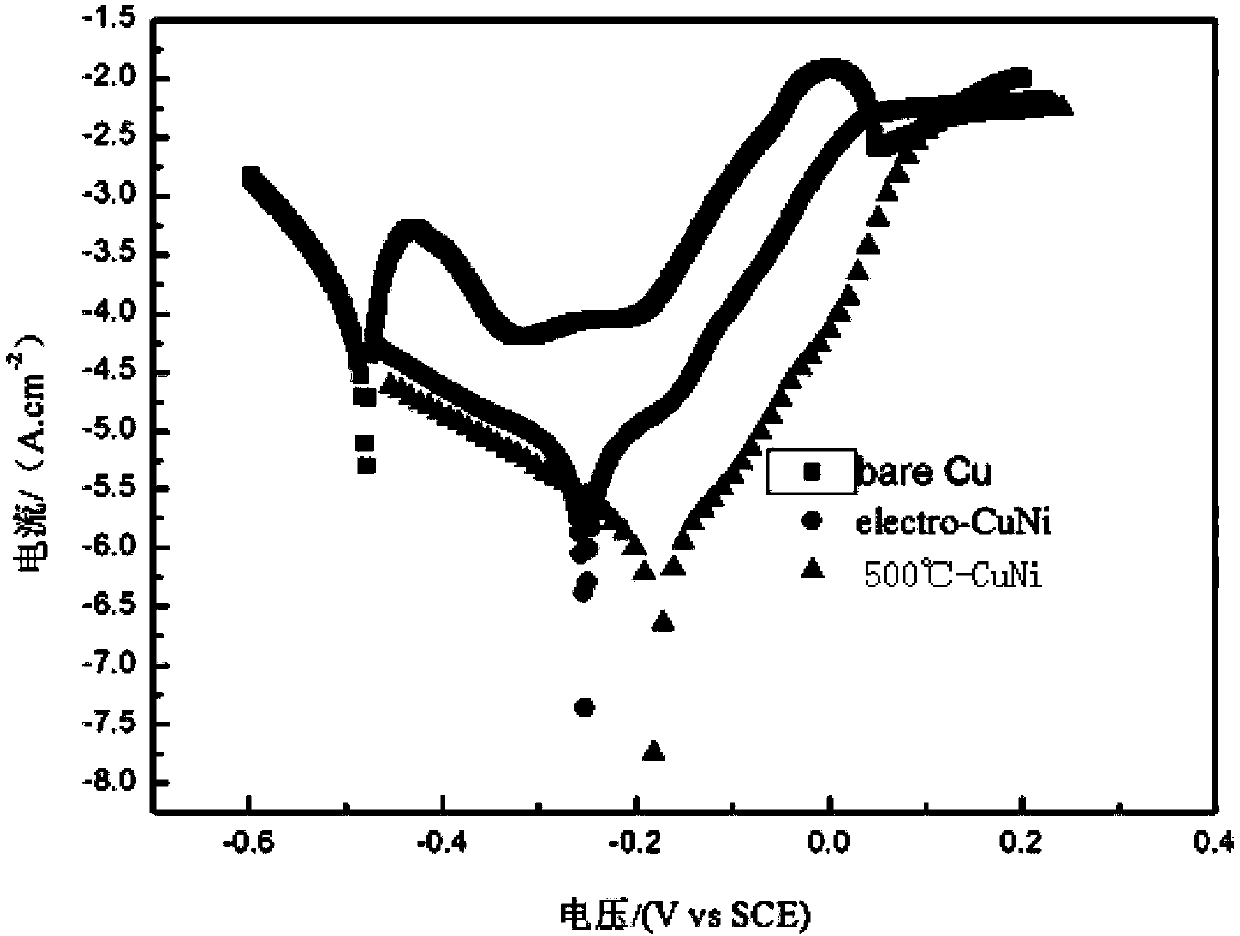

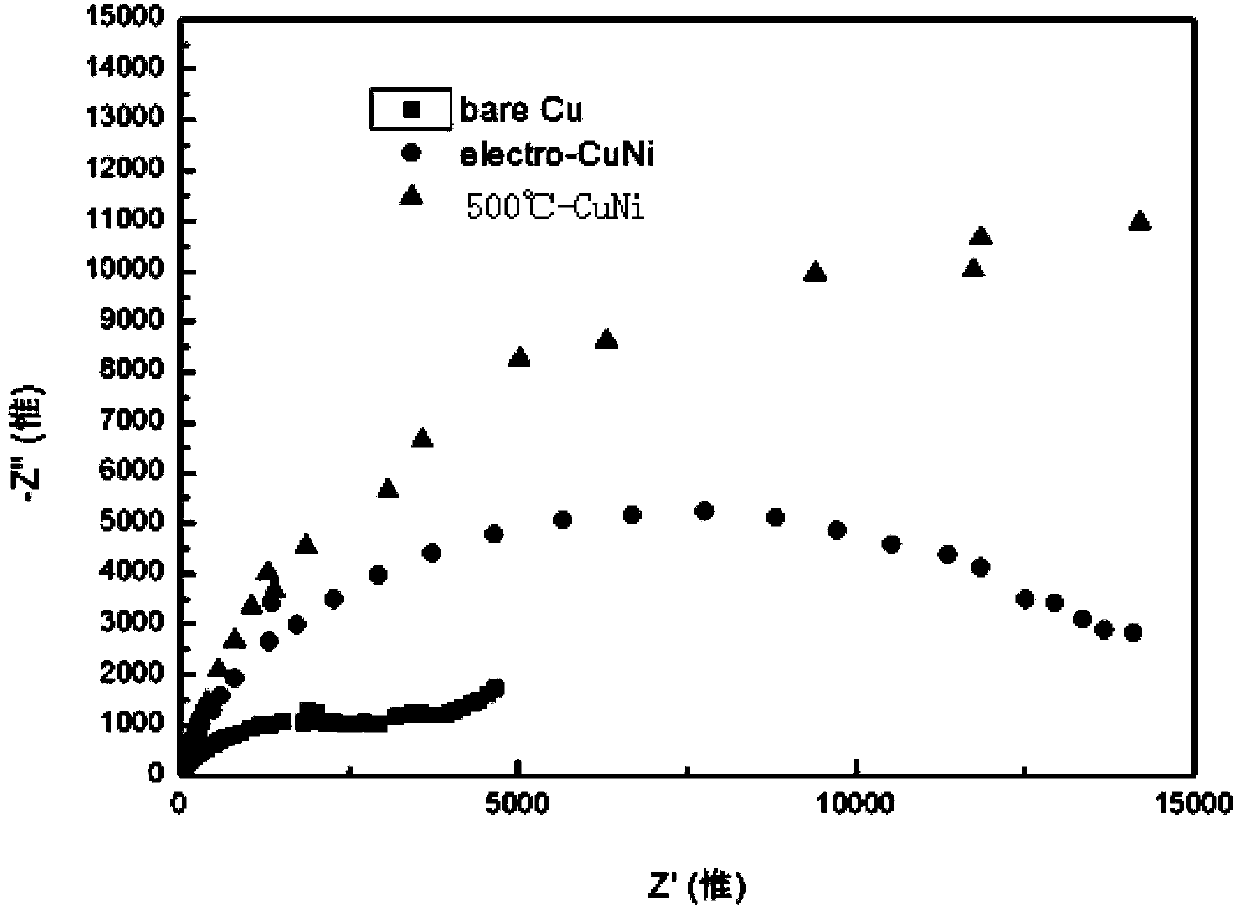

[0033] Example 1 Copper-nickel alloy was deposited on the surface of copper substrate by constant current technique.

[0034] 1) Metal surface pretreatment. The metal surface is polished sequentially with metallographic sandpaper of different meshes. After polishing, it is degreased and cleaned to make electrodes for use.

[0035] 2) Preparation solution: nickel sulfate 0.3M, copper sulfate 0.06M, surfactant sodium dodecylbenzenesulfonate 0.01g, metal ion complexing agent sodium citrate 0.10M.

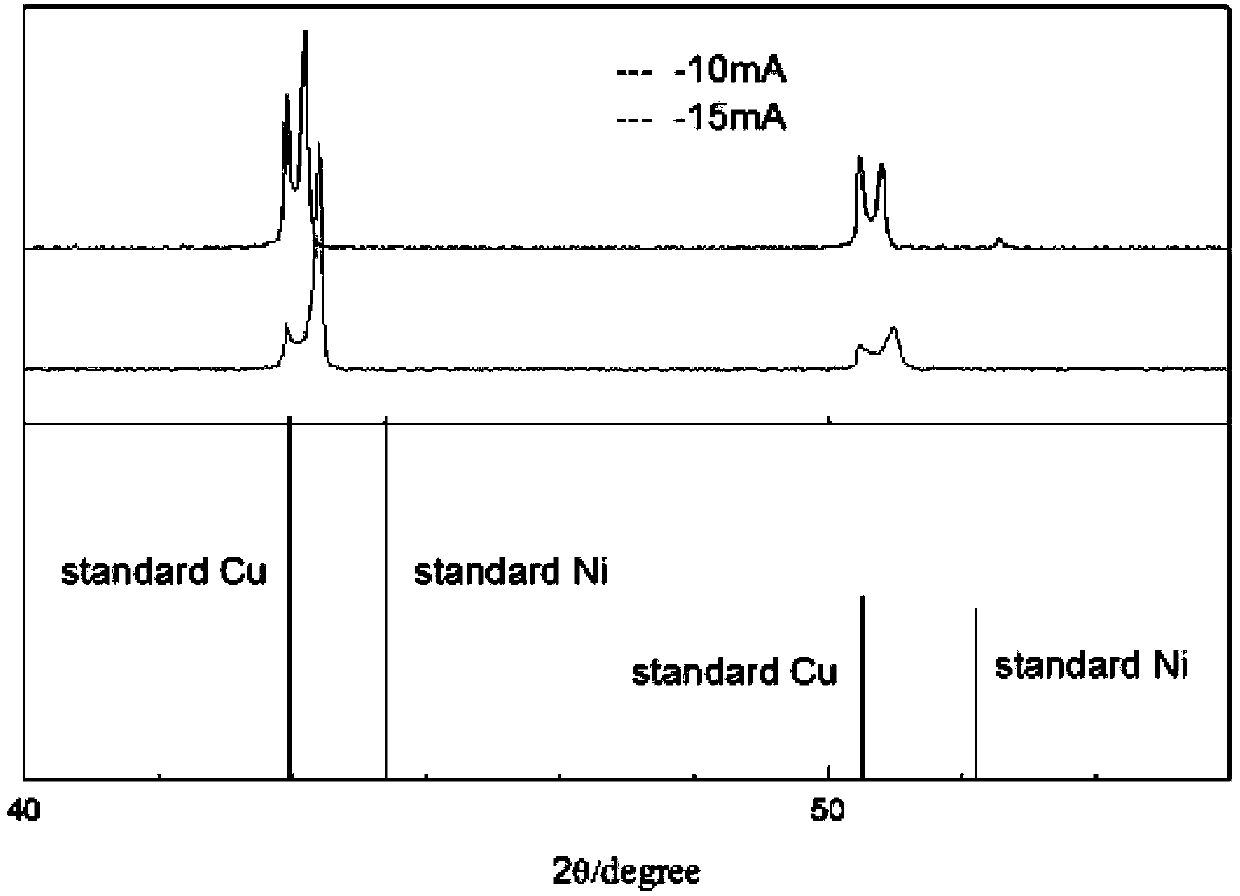

[0036] 3) Constant current deposition of copper-nickel alloy. The saturated calomel electrode was used as the reference electrode, the platinum electrode was used as the counter electrode, and the copper electrode was used as the cathode, and the film was formed at -10mA and -15mA for 900s.

[0037] 4) Vacuum heat treatment to make it dense. Sinter at 500°C and hold for 30 minutes to make it more compact and improve performance.

[0038] 5) Phase analysis. The prepared sample was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com