Method for precisely forming copper-nickel alloy flange pipes

A copper-nickel alloy, precision molding technology, applied in the direction of metal extrusion, metal processing equipment, metal extrusion dies, etc., can solve the problems of reducing oxide scale thickness, low production efficiency, shortening heating time, etc., to save waiting time , Improve production efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

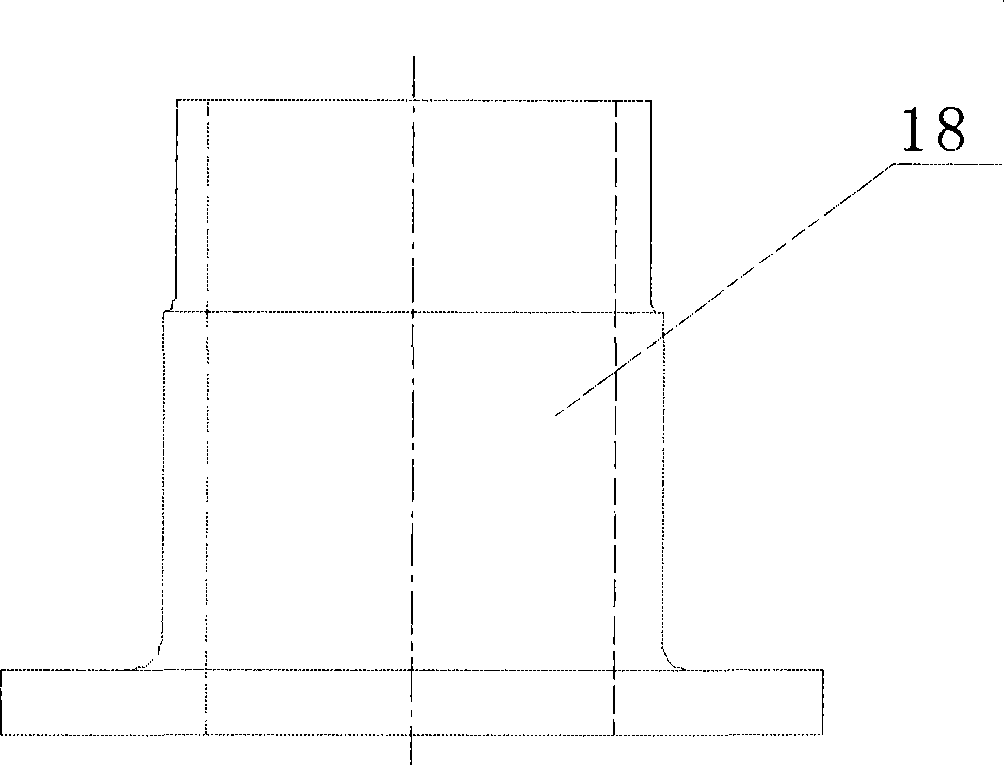

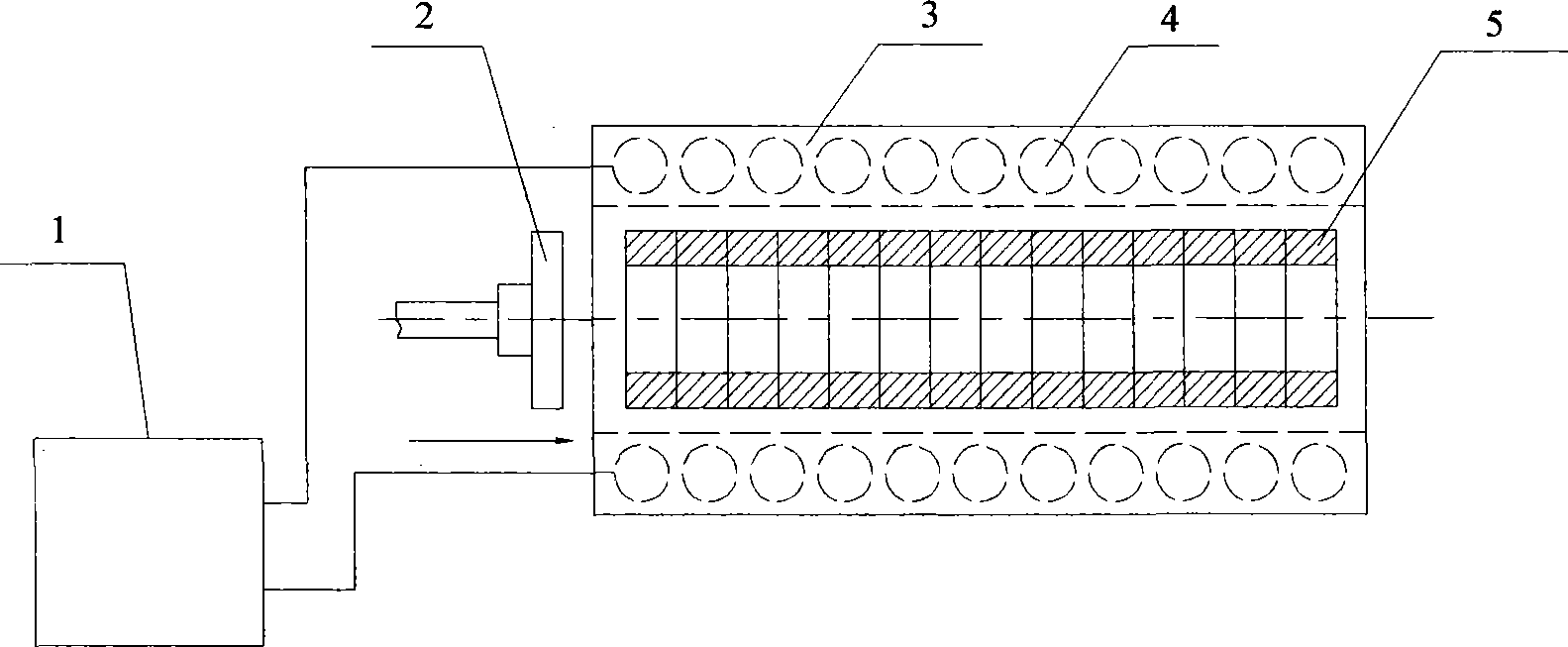

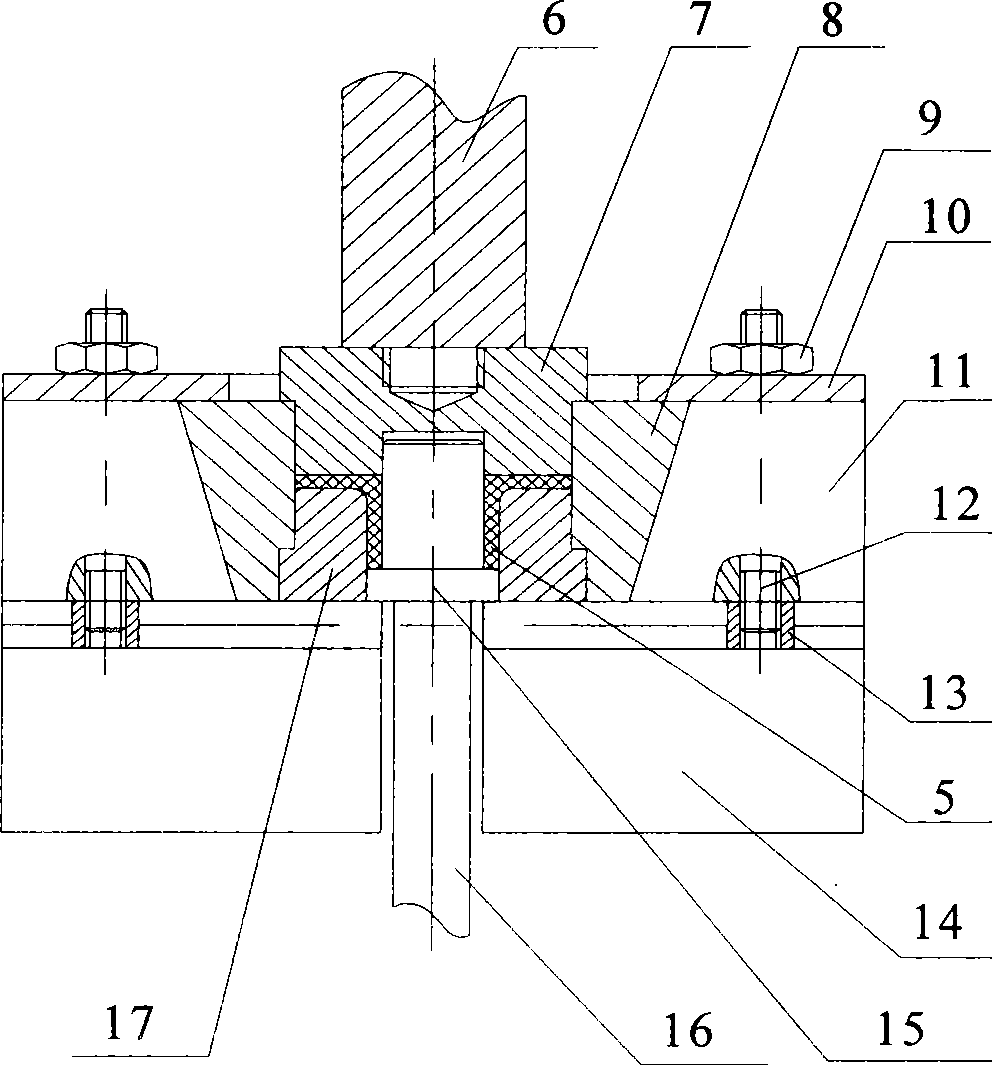

[0032] Embodiment 1: The precision forming method of making B10 copper-nickel alloy flange pipe fittings of DN50 specification

[0033] According to the length required by the DN50 specification, the tube blanks are cut on the sawing machine, the power of the induction coil is adjusted to 30KW by the medium frequency induction heater through the power supply, and the pushing frequency is 1 piece / 30 seconds. Put it in, heat it to 900℃~980℃ by the sensor, and push it out at a frequency of 1 piece / 30 seconds. The heated tube blank is installed on the lower mold of the 315T hydraulic press, and the upper mold is fixed on the lower end of the pressure rod of the hydraulic press. The positioning ring is installed on the base, and the lower mold and the core rod are first installed in the positioning ring, the lower mold is positioned by the outer mold, and the outer mold is fixed by the pressure ring and the nut; the lower mold, the outer mold, and the bottom plane of the core rod ar...

Embodiment 2

[0034] Embodiment 2: The precision forming method of making B10 copper-nickel alloy flange pipe fittings of DN80 specification

[0035] According to the length required by the DN80 specification, cut the tube blanks on the sawing machine, adjust the power of the induction coil to 40KW through the power supply of the intermediate frequency induction heater, and push the material at a frequency of 1 piece / 30 seconds. Put it in, heat it to 900℃~980℃ by the sensor, and push it out at a frequency of 1 piece / 30 seconds. The heated tube blank is installed on the lower mold of the 315T hydraulic press, and the upper mold is fixed on the lower end of the pressure rod of the hydraulic press. The positioning ring is installed on the base, the lower mold and the core rod are first installed in the positioning ring, the lower mold is positioned by the outer mold, and the outer mold is fixed by the pressure ring and the nut; the bottom plane of the lower mold, the outer mold and the core rod...

Embodiment 3

[0036] Embodiment 3: The precision molding method of making the B10 copper-nickel alloy flange pipe fitting of DN100 specification

[0037] According to the length required by DN100 specifications, the tube blanks are cut on the sawing machine, the power of the induction coil is adjusted to 50KW through the power supply of the intermediate frequency induction heater, and the pushing frequency is 1 piece / 40 seconds. Put it in, heat it to 900℃~980℃ by the sensor, and push it out at the frequency of 1 piece / 40 seconds. The positioning ring is installed on the base, the lower mold and the core rod are first installed in the positioning ring, the lower mold is positioned by the outer mold, and the outer mold is fixed by the pressure ring and the nut; the bottom plane of the lower mold, the outer mold and the core rod are close At the upper end of the base, the base and the positioning ring are connected by T-shaped blocks and bolts; the heated tube blank is set on the lower mold, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com