Flexible touch screen and preparation method thereof

A technology for flexible touch screens and manufacturing methods, applied in ion implantation plating, coatings, instruments, etc., can solve problems such as complicated manufacturing processes and affecting production efficiency, achieve good oxidation resistance, improve production efficiency, and avoid oxidative deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

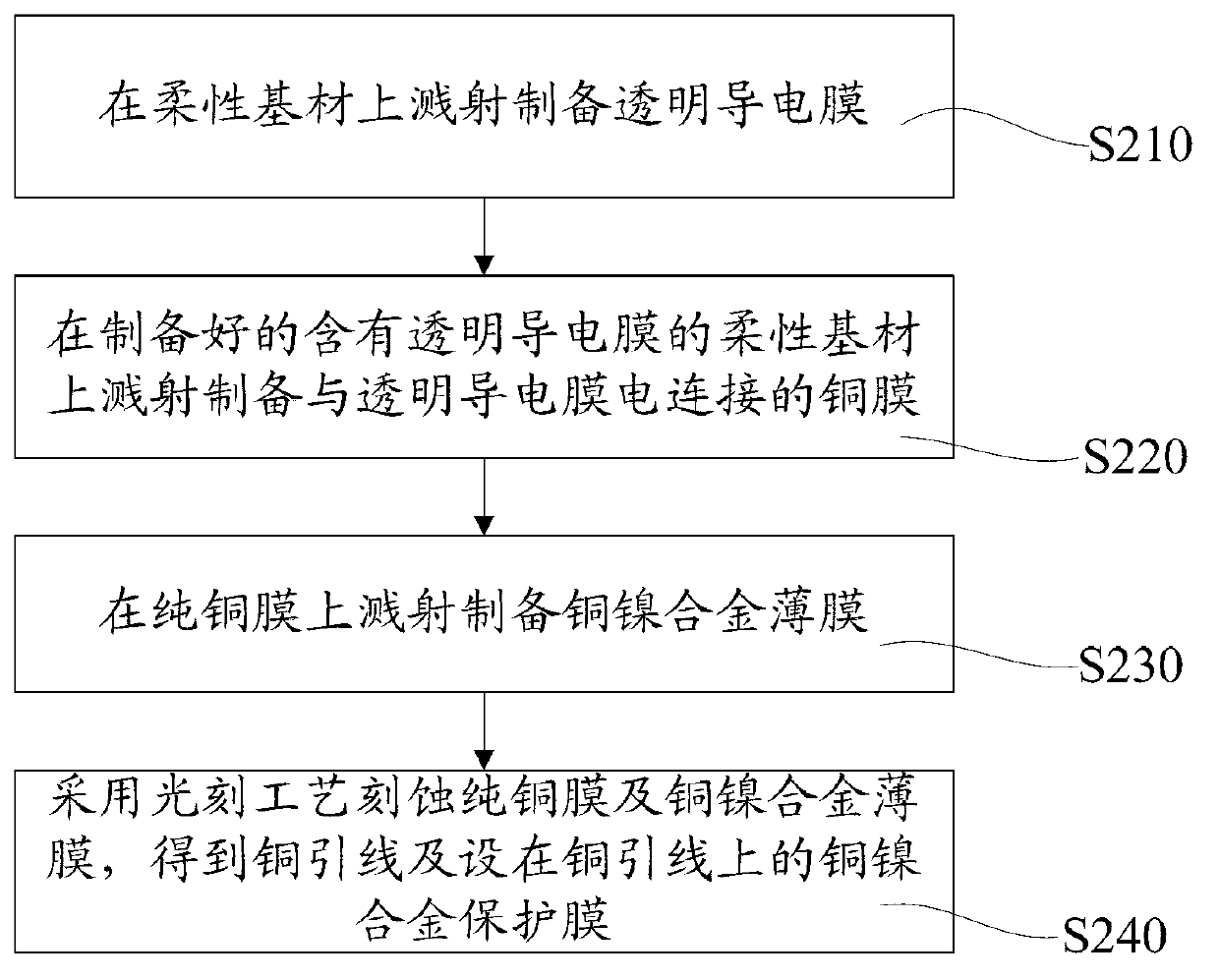

[0023] In the following, the flexible touch screen and its manufacturing method will be further described in detail mainly in conjunction with the accompanying drawings and specific embodiments.

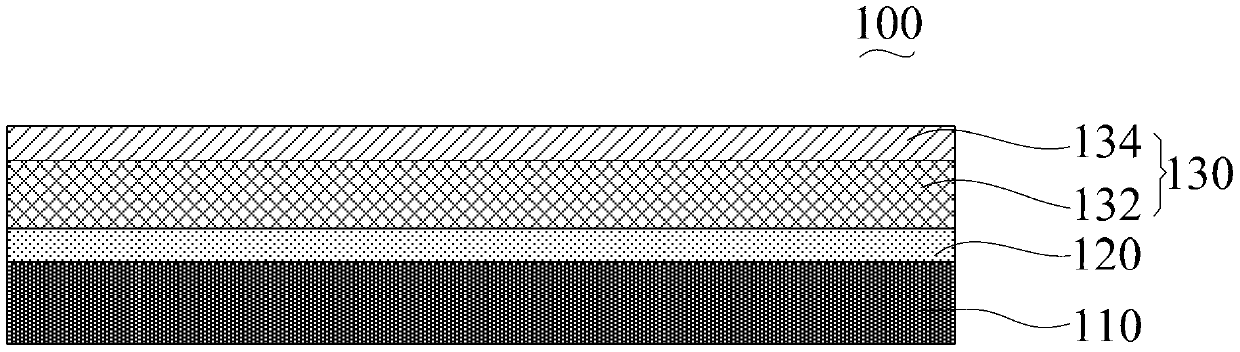

[0024] like figure 1 As shown, a flexible touch screen 100 according to an embodiment includes a flexible substrate 110 , a transparent conductive film 120 and electrode leads 130 .

[0025] The material of the flexible substrate 110 in this embodiment is polyethylene terephthalate (PET).

[0026] The transparent conductive film 120 is disposed on the flexible substrate 110 . The transparent conductive film 120 of this embodiment is a transparent ITO (indium tin oxide) conductive film with a thickness of 20-30 nm. It can be understood that, in other implementation manners, the material of the transparent conductive film 120 may also be a metal-doped n-type semiconductor oxide such as aluminum zinc oxide (AZO), gallium zinc oxide (GZO) or indium zinc oxide (IZO).

[0027] The elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com