Ultrasonic-assisted method for extracting flax-seed oil

A linseed oil and ultrasonic technology, applied in the production of fat oil/fat and fat production, can solve the problems that have not yet been found, and achieve the effects of avoiding oxidative deterioration, saving oil resources and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

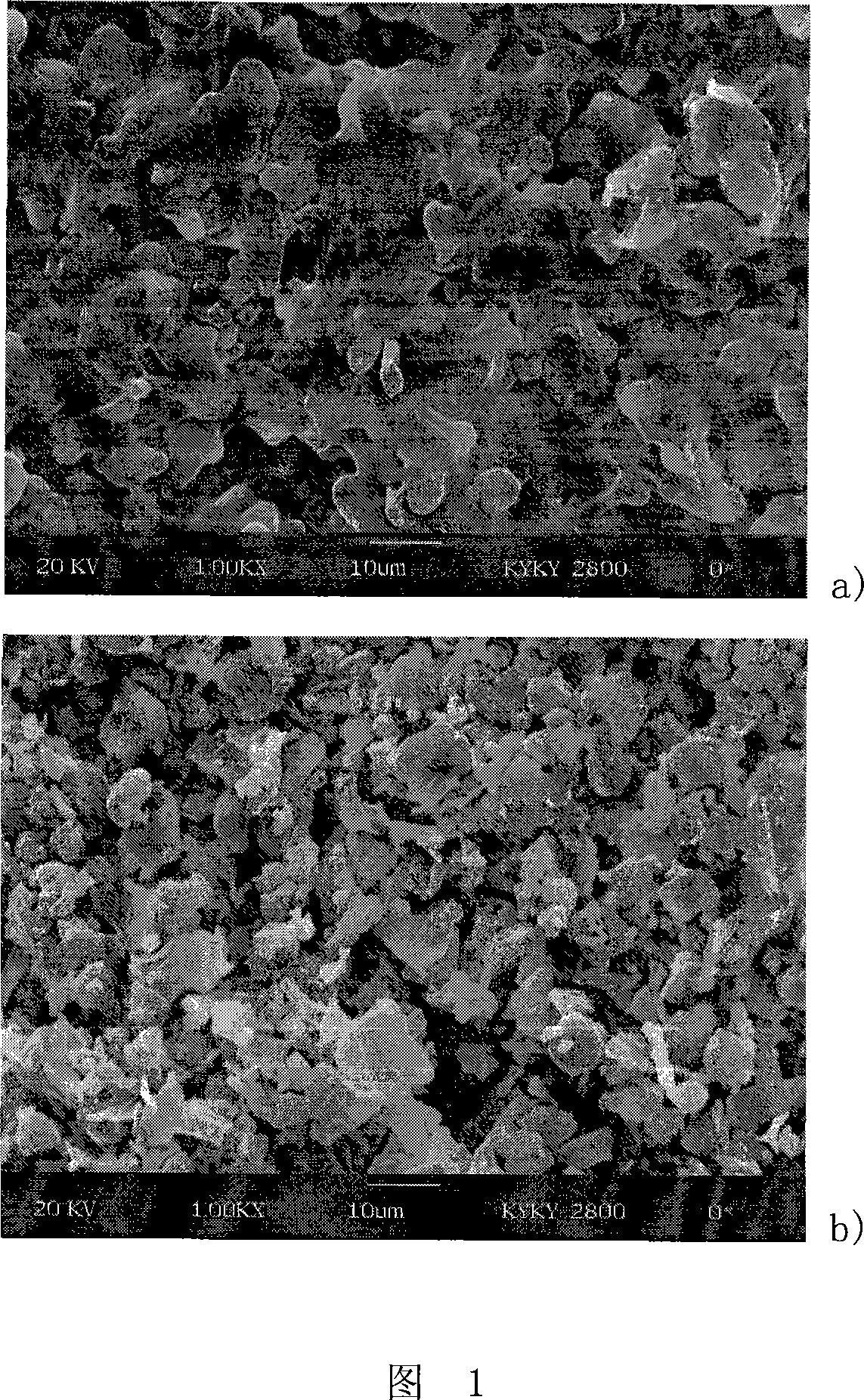

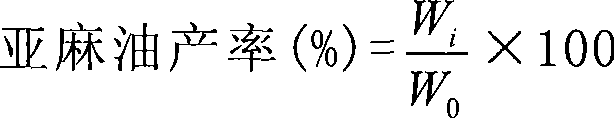

Image

Examples

Embodiment 1

[0036] The extraction and analysis of embodiment 1, linseed oil

[0037] Get 60g linseed (Hebei Zhangjiakou Liangyou Oil Food Co., Ltd.), randomly divided into 6 parts, each 10g, wherein 3 parts adopt the ultrasonic auxiliary solvent method of the present invention to extract linseed oil respectively; Extraction of linseed oil by solvent extraction. The specific extraction method and results are as follows:

[0038] 1. Ultrasonic-assisted solvent extraction of linseed oil

[0039] 1) Grinding of linseed: 10 g of linseed is put into a grinder and crushed to a particle size of 0.25-1.20 mm.

[0040] 2) Mix the crushed flaxseed with 40ml of n-hexane, at ultrasonic frequency 20kHz, ultrasonic intensity 1W / cm 2 , under the condition that the extraction temperature is 20° C., ultrasonic-assisted extraction is performed on the mixture for 30 minutes.

[0041] 3) Collect the extract by filtration.

[0042] 4) Place the extract in a rotary evaporator at 50° C. and concentrate unde...

Embodiment 2

[0061] The extraction and analysis of embodiment 2, linseed oil

[0062] Get 60g linseed (Hebei Zhangjiakou Liangyou Oil Food Co., Ltd.), randomly divided into 6 parts, each 10g, wherein 3 parts adopt the ultrasonic auxiliary solvent method of the present invention to extract linseed oil respectively; Extraction of linseed oil by solvent extraction. The specific extraction method and results are as follows:

[0063] 1. Ultrasonic-assisted solvent extraction of linseed oil

[0064] 1) Grinding of linseed: 10 g of linseed is put into a grinder and crushed to a particle size of 0.25-1.20 mm.

[0065] 2) Mix the crushed flaxseed with 60ml petroleum ether, at ultrasonic frequency 20kHz, ultrasonic intensity 5W / cm 2 , under the condition that the extraction temperature is 25° C., ultrasonic-assisted extraction is performed on the mixture for 30 minutes.

[0066] 3) Collect the extract by filtration.

[0067] 4) Put the extract in a rotary evaporator at 45° C. and concentrate un...

Embodiment 3

[0096] The extraction and analysis of embodiment 3, linseed oil

[0097] Get 60g linseed (Hebei Zhangjiakou Liangyou Oil Food Co., Ltd.), randomly divided into 6 parts, each 10g, wherein 3 parts adopt the ultrasonic auxiliary solvent method of the present invention to extract linseed oil respectively; Extraction of linseed oil by solvent extraction. The specific extraction method and results are as follows:

[0098] 1. Ultrasonic-assisted solvent extraction of linseed oil

[0099] 1) Grinding of linseed: 10 g of linseed is put into a grinder and crushed to a particle size of 0.25-1.20 mm.

[0100] 2) Mix the crushed flaxseed with 80ml of n-hexane, at ultrasonic frequency 30kHz, ultrasonic intensity 10W / cm 2 , under the condition that the extraction temperature is 35° C., ultrasonic-assisted extraction is performed on the mixture for 60 minutes.

[0101] 3) Collect the extract by filtration.

[0102] 4) Place the extract in a rotary evaporator at 50° C. and concentrate und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com