Method for preparing hexagonal boron nitride film

A hexagonal boron nitride, thin film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the uneven thickness of hexagonal boron nitride continuous film, between tens of nanometers to ten microns , it is difficult to meet the needs of the application and other problems, to achieve the effect of low cost, wide window and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A copper-nickel alloy foil substrate is prepared first. In this embodiment, a copper foil with a thickness of 25 μm is selected. Preferably, the surface of the copper foil is polished using a classic electrochemical polishing process. Among them, the electrochemical polishing solution is a phosphoric acid solution with a volume ratio of 85%, and the current density is 0.2A / cm 2 , the polishing time is 1-2min. After polishing, use acetone and isopropanol to ultrasonically clean for 10min respectively, and then use a nitrogen gun to dry the polished copper foil to obtain a clean surface with a surface roughness below 50nm and a thickness of about 20μm. copper foil.

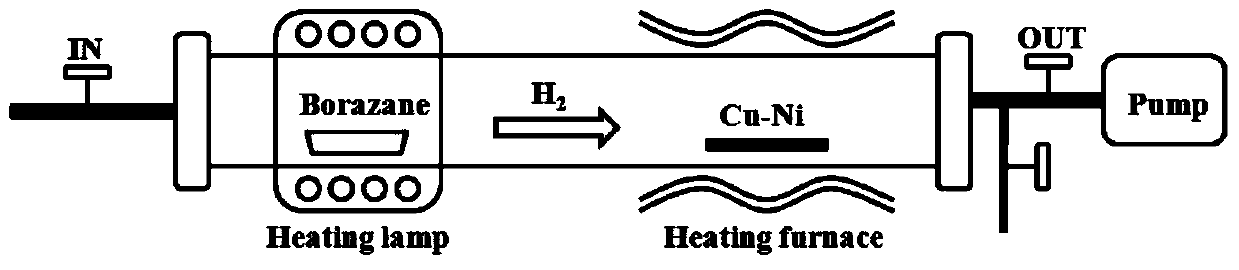

[0043] Then put the polished and cleaned copper foil on the figure 1 Annealed at 1050°C for 2h in the tube furnace shown. The annealing process is carried out under normal pressure, the selected atmosphere is hydrogen and argon, and the flow rate ratio Ar:H 2 =5:1, the partial pressure ratio of argon and h...

Embodiment 2

[0051] The difference between this embodiment and the first embodiment is that the growth time of the hexagonal boron nitride film in the first embodiment, that is, the heating time of the solid source ammonia borane is extended to 40 minutes, and the rest of the process parameters are the same as the first embodiment.

[0052] The results of this embodiment: as Figure 4 Shown, compared with embodiment one, along with the increase of growth time, reaction proceeds further, from Figure 4 It can be seen that the hexagonal boron nitride crystal domains are further enlarged, and the maximum side length can reach 60 μm. After the growth was completed, the prepared films were transferred to SiO 2 / Si substrate, its XPS (X Photoelectron Spectroscopy) spectrum is as follows Figures 5a-5c As shown, the binding energies of N1s and B1s are 398.1eV and 190.5eV, respectively, and the atomic ratio B:N=1:1.01, which confirms the existence of only B-N bonds in the film, which is consiste...

Embodiment 3

[0054] The difference between this embodiment and the first embodiment is that the growth time of the hexagonal boron nitride thin film in the first embodiment is extended to 60 minutes, and the temperature of the substrate during growth is increased to 1085° C., and the rest of the process is the same as the first embodiment.

[0055] Results of this example: by increasing the temperature on the surface of the copper-nickel alloy foil substrate during growth, the nucleation density of the hexagonal boron nitride crystal domain is reduced, and the size of the prepared crystal domain is further increased with the further increase of the growth time. Big. Such as Figure 6 As shown, the hexagonal boron nitride crystal domain side length prepared under this growth condition can reach up to 100 μm, which is an order of magnitude higher than that reported in the existing literature. It should be noted that with the increase of the size, the boundary of the crystal domain begins to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com