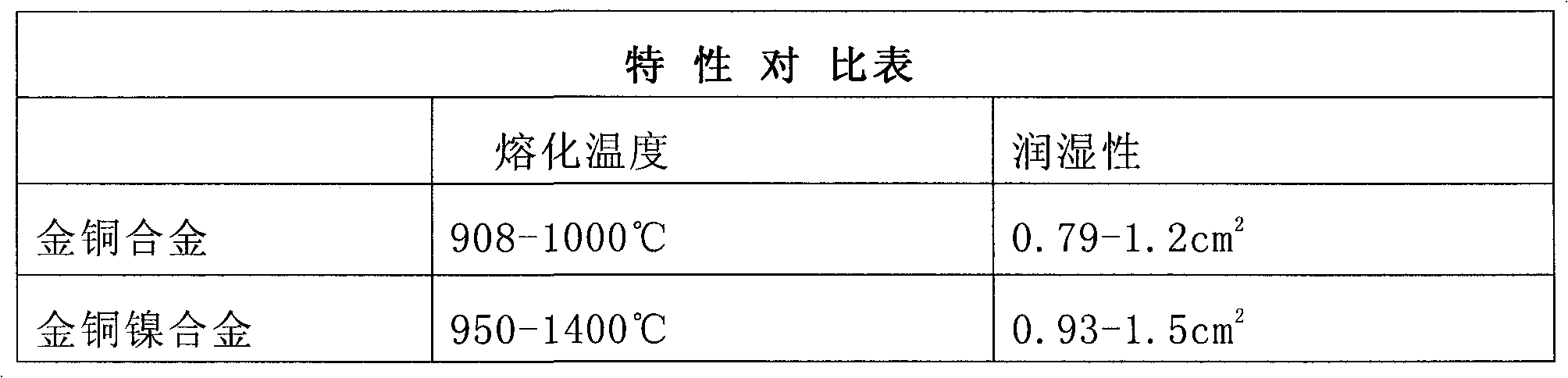

Gold-copper-nickel alloy, preparation method and application thereof

A nickel alloy and gold-copper technology, applied in the field of gold-copper-nickel alloy and its preparation, can solve the problems of cracking and brittle fracture, the strength of brazing joints, and the difficulty of alloy processing and production, so as to prevent cracking, improve welding quality, and easily processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

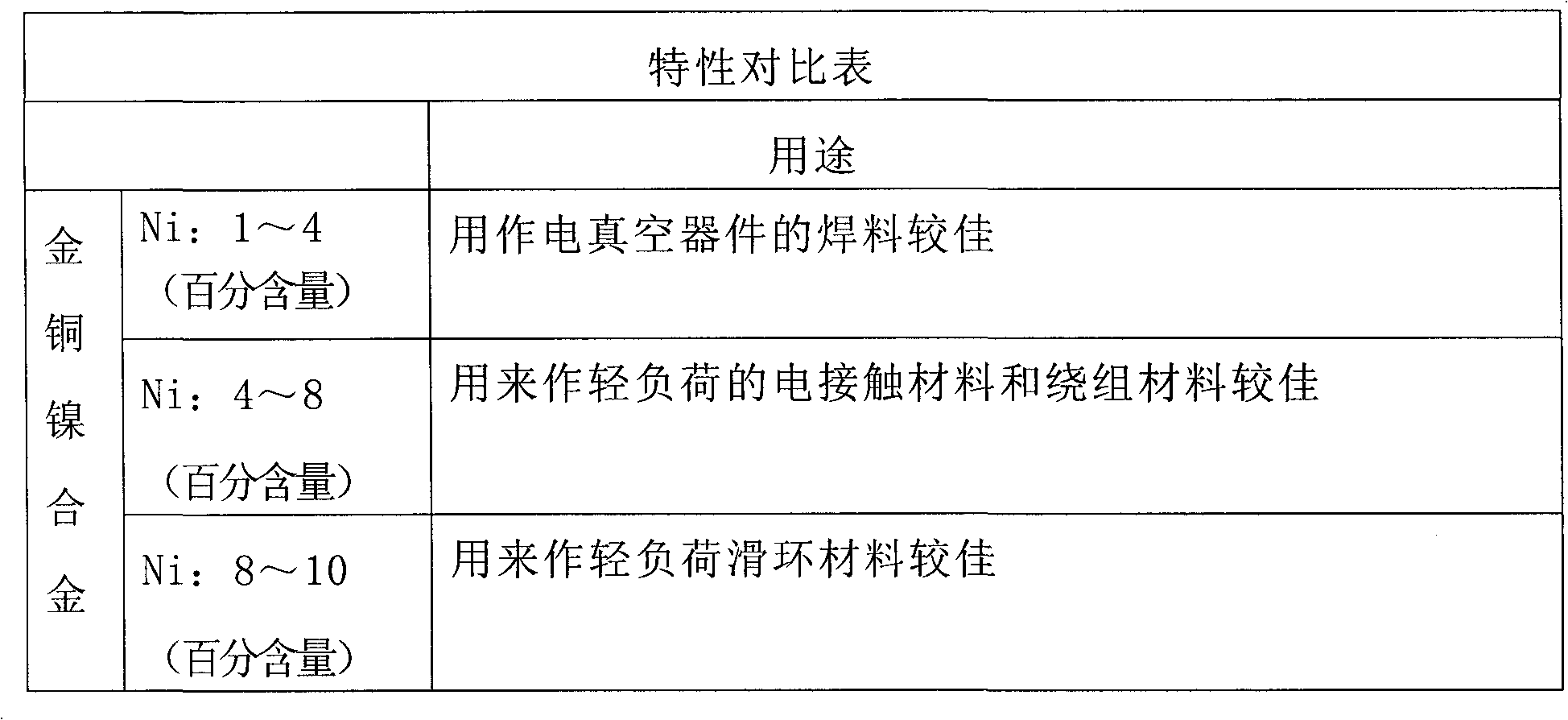

[0033] Adopt following preparation method to prepare gold-copper-nickel alloy, its composition and mass percentage are: Au: 81.5%, Cu: 15.5%, Ni: 3% (abbreviated as AuCu 15.5 Ni 3 ).

[0034] The preparation process is as follows:

[0035] a) Prepare raw materials: Purify gold 4N (99.99%) raw materials by electrolysis to remove impurity elements (mainly control Pb, Sb, In, Bi and rare earth elements), so that the purity of gold can reach more than 5N (>99.999%) ), purchased nickel (nickel with 4N purity is better) and oxygen-free copper raw materials; calculate and weigh according to the above-mentioned composition and mass percentage ratio.

[0036] b) putting the raw materials into the graphite crucible of the vacuum drawing casting furnace in turn;

[0037] c) Vacuumize until the degree of vacuum is 5Pa;

[0038] d) heating up, controlling the heating rate to be 20-25°C / min;

[0039] e) Control the temperature in the crucible at 1100°C-1150°C and refine for 3 to 5 minu...

Embodiment 2

[0047] Adopt the method described in embodiment 1 to prepare gold-copper-nickel alloy, its composition and mass percentage are: Au: %, Cu: 1.5%, Ni: 7.5% (being called for short AuCu 1.5 Ni 7.5 ), and control the continuous casting temperature at 1200-1250°C.

[0048] The gold-copper-nickel alloy prepared by the method described in Example 2 of the present invention is used as a light-load electrical contact material and winding material.

Embodiment 3

[0050] Adopt the method described in embodiment 1 to prepare gold-copper-nickel alloy, its composition and mass percentage are: Au: %, Cu: 15%, Ni: 10% (being called for short AuCu 15 Ni 10 ), and control the continuous casting temperature at 1100-1150°C.

[0051] The gold-copper-nickel alloy prepared by the method described in Example 3 of the present invention is used as a light-duty slip ring material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com