Method for preparing silver-magnesium-nickel alloy billets

A technology of silver-magnesium-nickel alloy, which is applied in the field of vacuum precision melting and casting preparation of silver-magnesium-nickel alloy ingots, can solve the problems of oxidized surface foaming, burning loss and difficult control of sheets, etc., and achieve constant quality, precise control, and reliable composition. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. Process

[0014] (1) Preparation of silver-magnesium master alloy: After degassing 920 grams of silver (purity 99.99%) in a vacuum induction melting furnace, 80 grams of electrolytic Mg (purity 99.95%) were added to melt and cast silver-magnesium alloy ingots. Sampling is carried out for compositional analysis, containing magnesium: 7.85%, and then the silver-magnesium alloy ingot is rolled into sheets, and cut into blocks for later use.

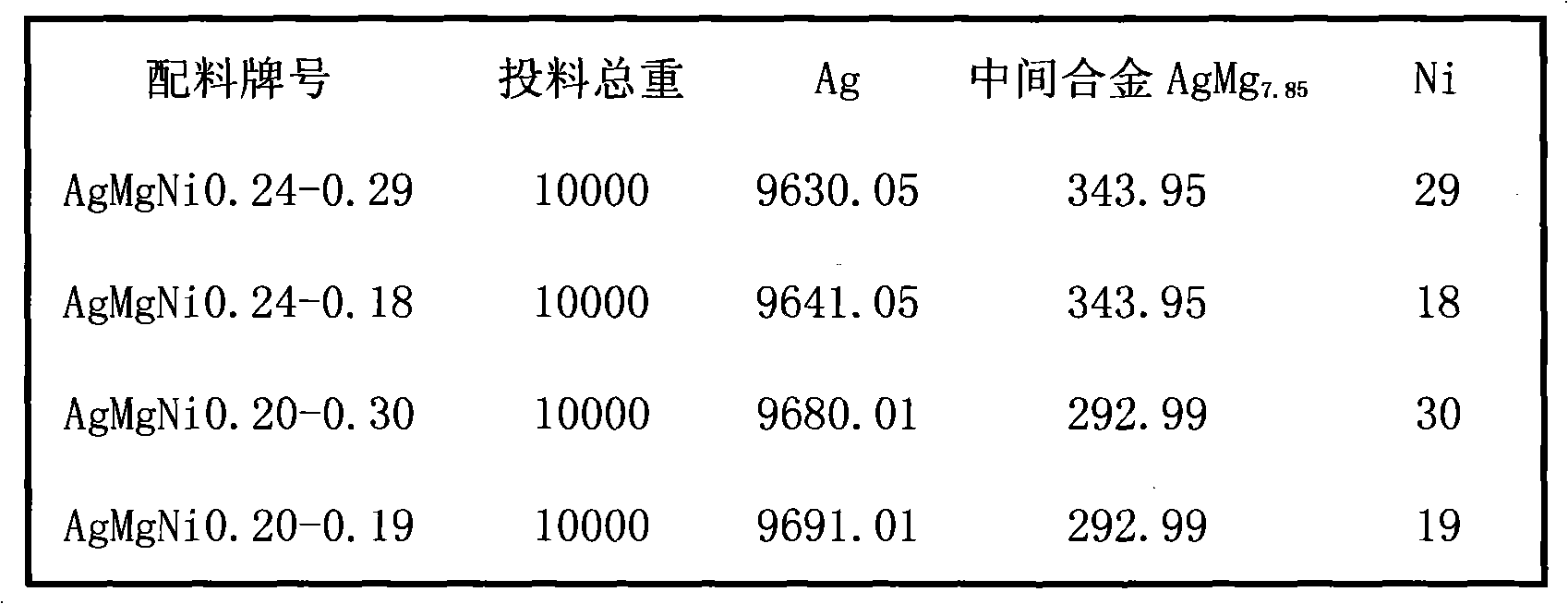

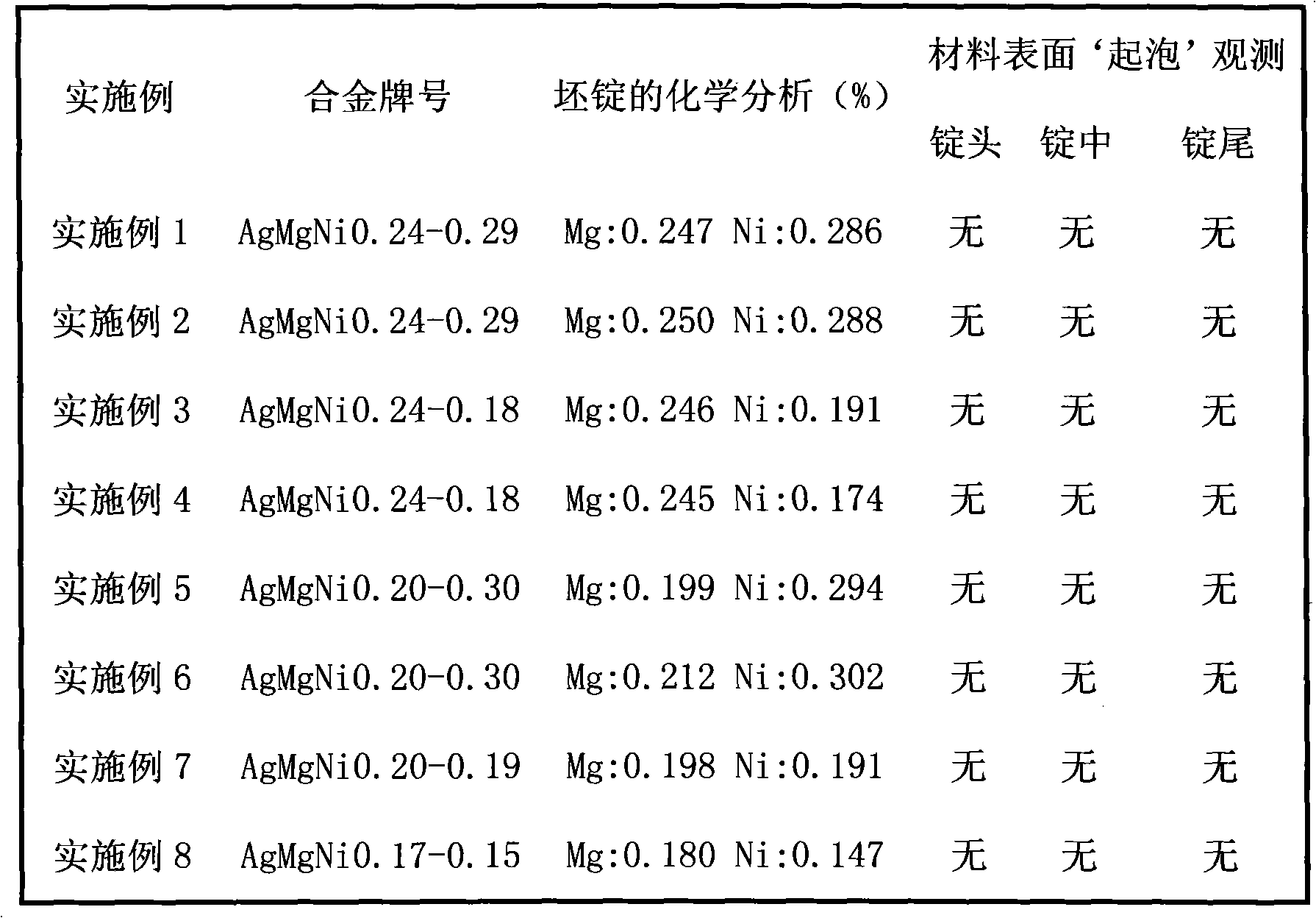

[0015] (2) Silver-magnesium-nickel alloy batching: Feed the commonly used alloy grades separately, with a total of 10,000 grams per furnace, and a total of 8 furnaces (see Table 2 below). All magnesium is added in the form of silver-magnesium master alloy, and the burning loss rate of magnesium is considered to be 0.03% of the total weight of Mg material; ②Each furnace of silver-magnesium master alloy is divided into two equal parts and wrapped with silver skin to facilitate secondary feeding; ③ Roll the nickel sheet into a thin s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com