Vacuum melting furnace for preparing fusion casting type production of molybdenum from worn-out molybdenum

A vacuum smelting furnace and waste technology, which is applied in the field of vacuum smelting furnaces and vacuum smelting electric furnaces, can solve problems such as the inability to melt and cast molybdenum products, the inability to realize the recycling of waste molybdenum resources, and the inability to achieve waste molybdenum recycling, smelting and casting capabilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

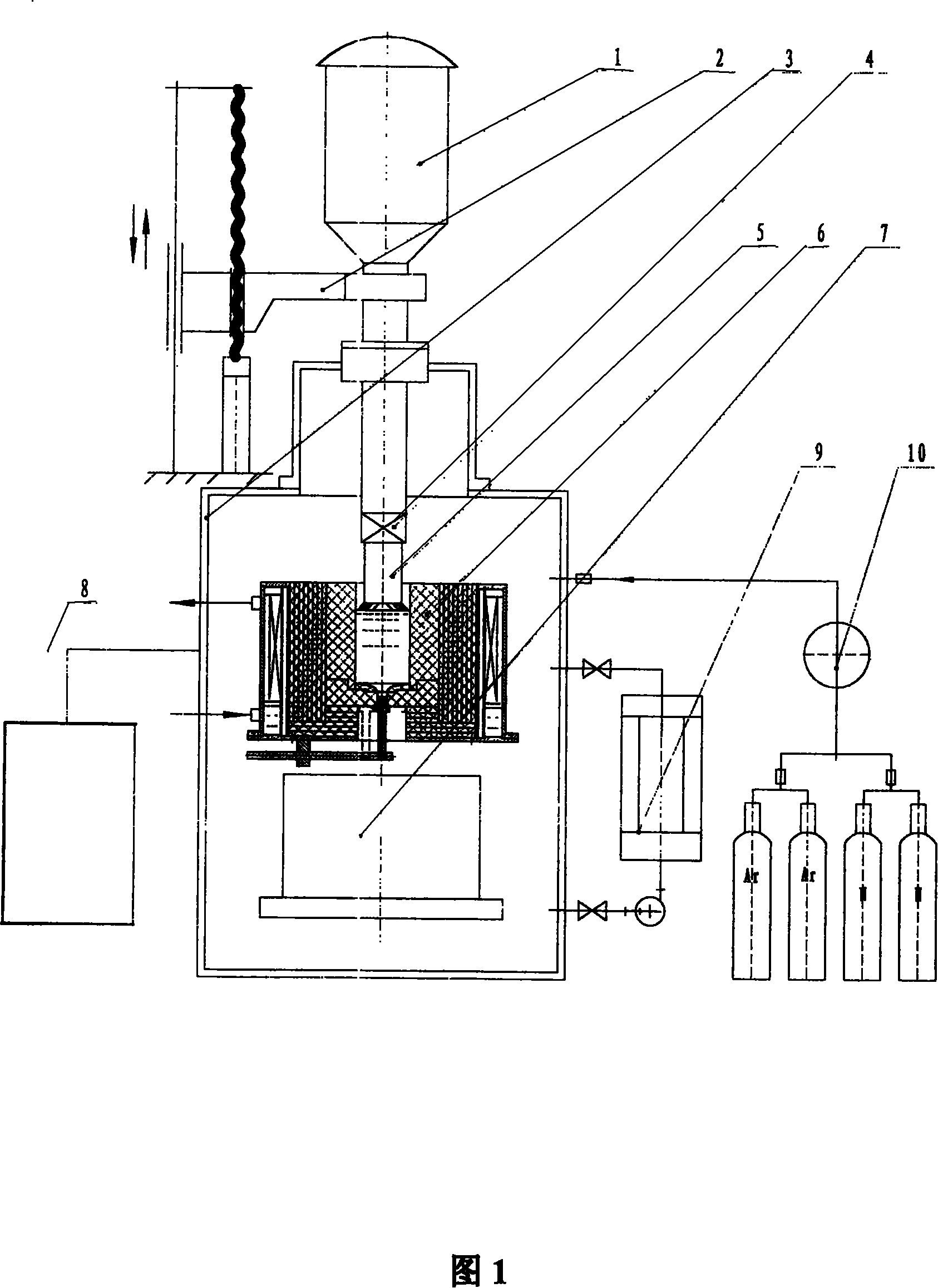

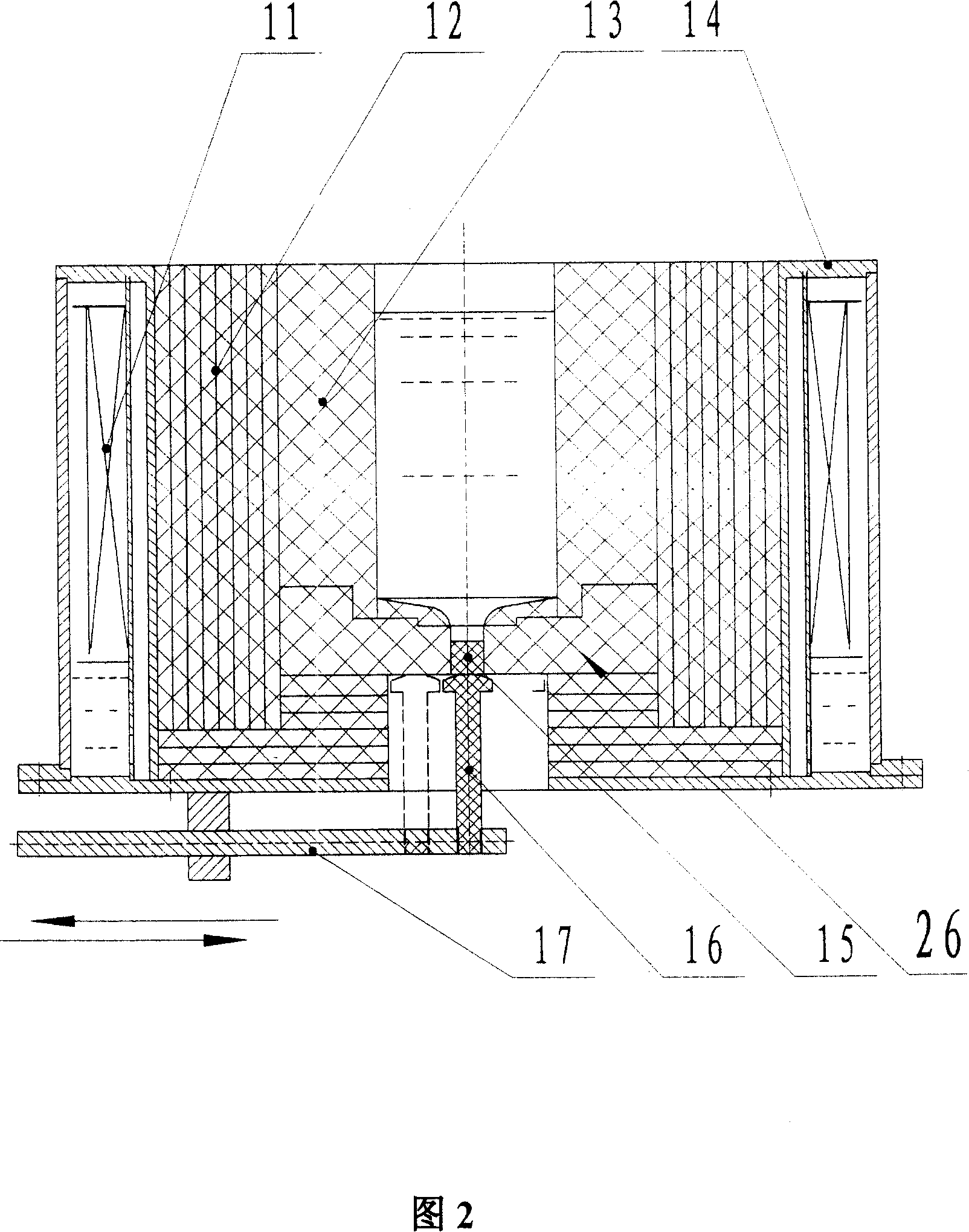

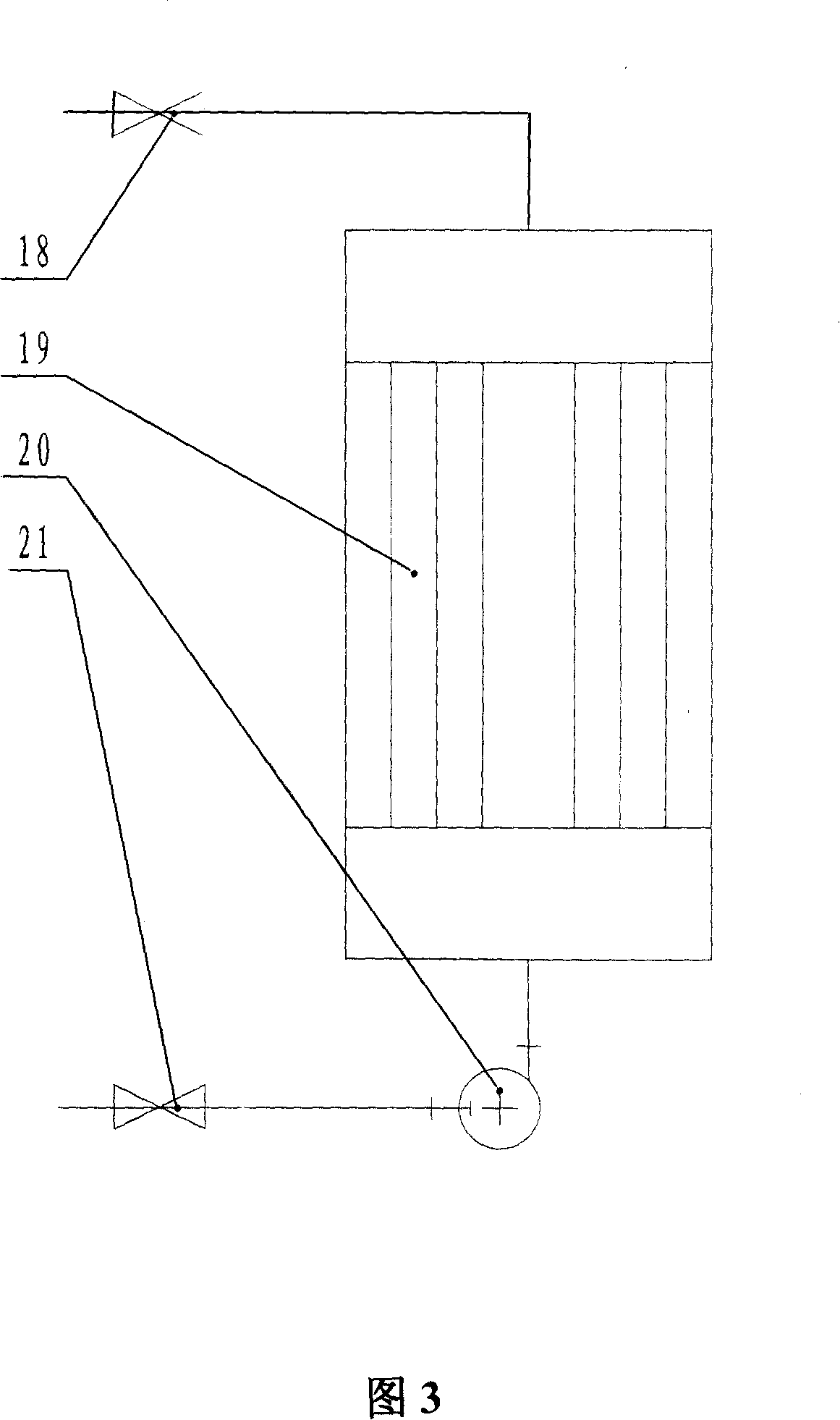

[0014] As shown in Figure 1, 3 is a vacuum chamber, and a crucible 6 is arranged in the vacuum chamber. The bottom of the crucible is provided with a pouring mold device 7 . The pouring mold and the crucible are fixedly connected to a door car (not shown). Push it into the vacuum chamber during smelting, and pull out the vacuum chamber after the smelting is over and the cast molybdenum parts are cooled. A hollow non-consumable electrode 5 is arranged above the crucible, and the hollow non-consumable electrode 5 is fixedly connected to the hollow electrode rod 4 through a clamp. The hollow non-consumable electrode acts as the cathode during the smelting process. And the crucible 6 and the material in the crucible are used as anode during the melting process. The upper end of the hollow electrode rod is connected with the electrode rod transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com