Hyperbranched polyester modified acrylic resin and preparation method thereof

A technology of acrylic resin and hyperbranched polyester, applied in the direction of coating, etc., can solve the problems of poor controllability, complicated preparation process, high production cost, etc., and achieve the effect of low production cost, wide sources and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

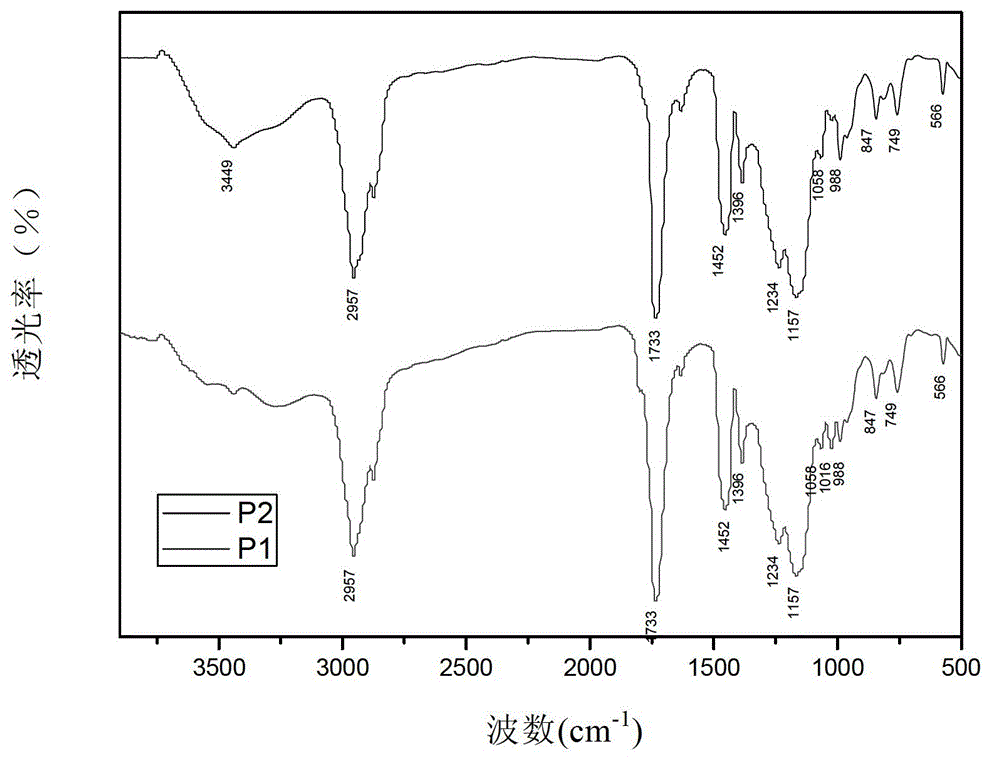

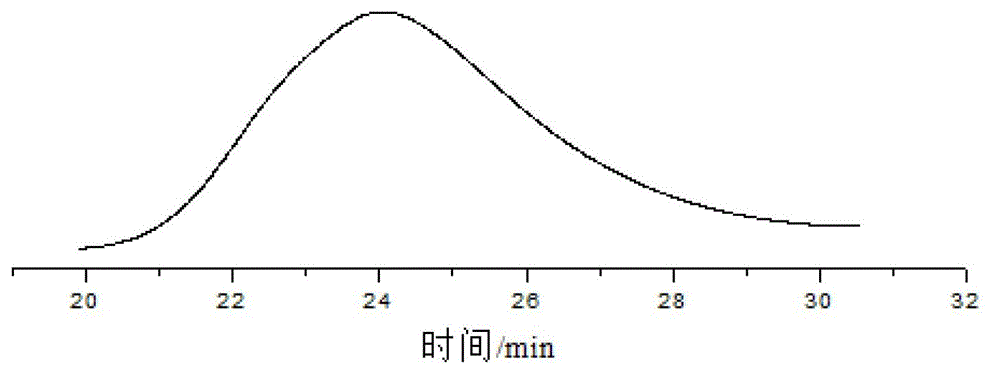

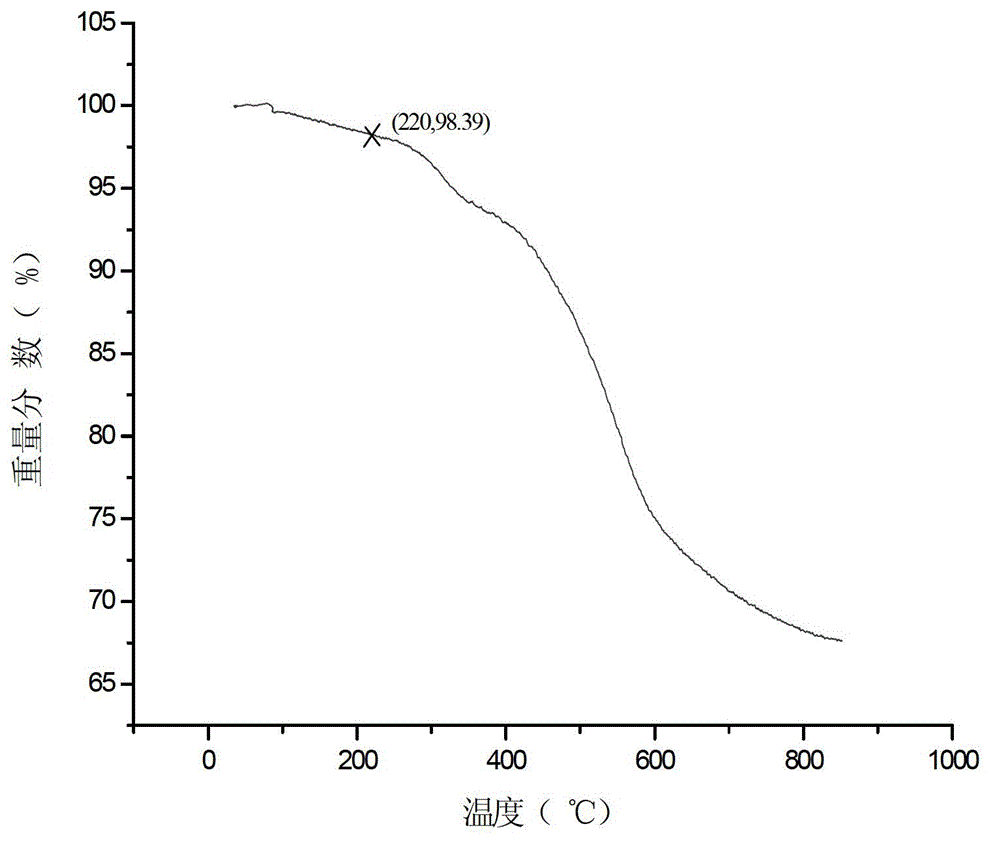

[0024] (1) Mix 0.7g of p-phenylmethanesulfonic acid, 13.6g of pentaerythritol and 53.54g of dimethylolpropionic acid (DMPA), react at 160°C for 2.5h, and vacuumize (740mmHg) at the same time to obtain a transparent yellowish liquid; Then add 107.28g DMPA to the system, and react under vacuum (740mmHg) at 160°C until the acid value of the resin is less than 10mg KOH / g, pour it out, and obtain hyperbranched polyester after cooling.

[0025] (2) Add 80g of xylene to a four-necked flask equipped with a condenser, stirrer and thermometer, raise the temperature to 140±2°C, then add 3g of acrylic acid, 28g of butyl acrylate, 32g of methyl methacrylate and 2g of BPO and A mixed solution composed of 1g of chain transfer agent n-dodecanethiol was evenly put into the dropping funnel; it was evenly dropped into a four-necked flask filled with xylene for 4~5h, and then kept at 140±2°C for 1h, and then added 0.35 g initiator BPO and 14g xylene were added to a four-neck flask with a dropping...

Embodiment 2

[0032] (1) Mix 0.7g of p-phenylmethanesulfonic acid, 13.6g of pentaerythritol and 53.64g of dimethylolpropionic acid (DMPA), react at 160°C for 2.5h, and vacuumize (740mmHg) at the same time to obtain a transparent yellowish liquid; Then add 107.28g DMPA to the system, and react under vacuum (740mmHg) at 160°C until the acid value of the resin is less than 10mg KOH / g, pour it out, and obtain hyperbranched polyester after cooling.

[0033](2) Add 70g of xylene to a four-neck flask equipped with a stirrer, thermometer, dropping funnel and reflux condenser, add 32g of methyl methacrylate, 28g of butyl acrylate, 3g of acrylic acid, 2g of BPO and 1g of n-decyl Add dithiol into the dropping funnel, heat under stirring, and control the temperature at 120°C, that is, when the solvent reaches the reflux state, evenly drop the mixed monomer and initiator into the reactor within 4.0h, when mixed After the monomer is added dropwise, add a small amount of initiator, keep warm for 1.0h, the...

Embodiment 3

[0036] (1) Mix 0.9g p-phenylmethanesulfonic acid, 13.6g pentaerythritol and 53.64g dimethylolpropionic acid (DMPA), react at 180°C for 2.5h, and vacuumize (740mmHg) at the same time to obtain a transparent yellowish liquid; Then add 107.28g DMPA to the system, and react under vacuum conditions (740mmHg) at 160°C until the acid value of the resin is less than 10mg KOH / g, pour it out, and obtain hyperbranched polyester after cooling.

[0037] (2) Add 70g of xylene to a four-neck flask equipped with a stirrer, thermometer, dropping funnel and reflux condenser, add 32g of methyl methacrylate, 28g of butyl acrylate, 3g of acrylic acid, 2g of BPO and 1g of n-decyl Add dithiol into the dropping funnel, heat under stirring conditions, and control the temperature at 120°C, that is, when the solvent reaches the reflux state, evenly drop the mixed monomer and initiator into the reactor within 4.0h, when mixed After the monomer is added dropwise, add a small amount of initiator, keep it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com