Wear resistant blade and processing method thereof

A technology of wear-resistant type and process method, which is applied in the direction of chemical instruments and methods, metal material coating process, lamination, etc., to achieve the effect of high corrosion resistance and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

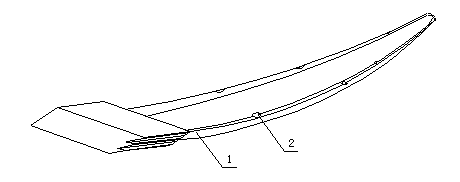

[0025] This wear-resistant blade is to add a wear-resistant layer 2 on the outer surface of the blade body 1 through the vacuum cladding process, see figure 1 , the thickness of the wear-resistant layer is 0.01 ~ 2mm, the wear-resistant layer 2 is made of alloy powder and binder, in which the alloy powder is a self-fluxing alloy powder with high wear resistance and high corrosion resistance, and vacuum cladding is adopted Technology, the metallurgical combination of the alloy powder and the surface of the blade is achieved, and then the blade with high wear resistance and high corrosion resistance is formed through other processing processes.

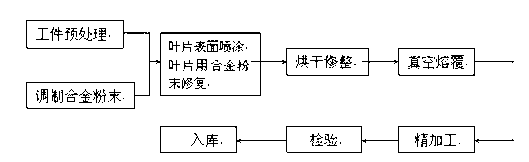

[0026] Such as figure 2 As shown in the flow chart of increasing the wear-resistant layer in the vacuum cladding process, the blades with high wear resistance and high corrosion resistance are processed through the following steps:

[0027] Step 1. First, pre-treat the blades. The pre-treatment mainly includes blade size reservation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com