Structure of melted-plated compound coating by vacuum fusion covering+chemical plating and preparation method thereof

A vacuum cladding and composite coating technology, applied in liquid chemical plating, coating, superimposed layer plating, etc., can solve the problems of agglomeration, complex preparation, low bonding strength between coating and substrate with comprehensive performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

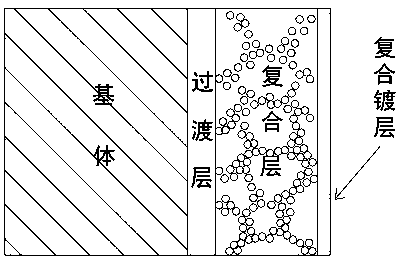

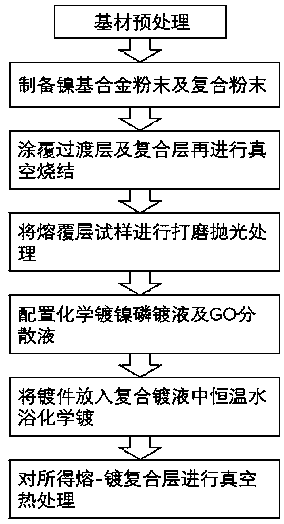

[0020] The present invention relates to the structure and preparation method of vacuum cladding + electroless plating melting-plating composite coating, the structure of vacuum cladding + chemical plating melting-plating composite coating, the whole cladding layer is composed of nickel-based tungsten carbide composite layer, transition layer and diffusion-affected area; electroless nickel-phosphorus graphene oxide composite coating is deposited on the surface of the cladding composite layer; vacuum heat treatment is performed on the fusion-plating composite layer at 400~600°C to form a diffusion connection between the electroless coating and the cladding layer.

[0021] In view of the deficiency that the surface coating obtained by the existing surface modification technology is a single-performance coating, the problem to be solved by the present invention is to provide a composite cladding layer and a composite coating layer that obtains three-dimensional texture structure cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com