Non-vacuum smelting method of CuCrZr alloy

A non-vacuum smelting, copper-chromium-zirconium technology is applied in the field of smelting copper alloy materials, which can solve the problems of restricting the mass production, promotion and application of copper-chromium-zirconium alloy materials, and achieve the effect of improving production efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

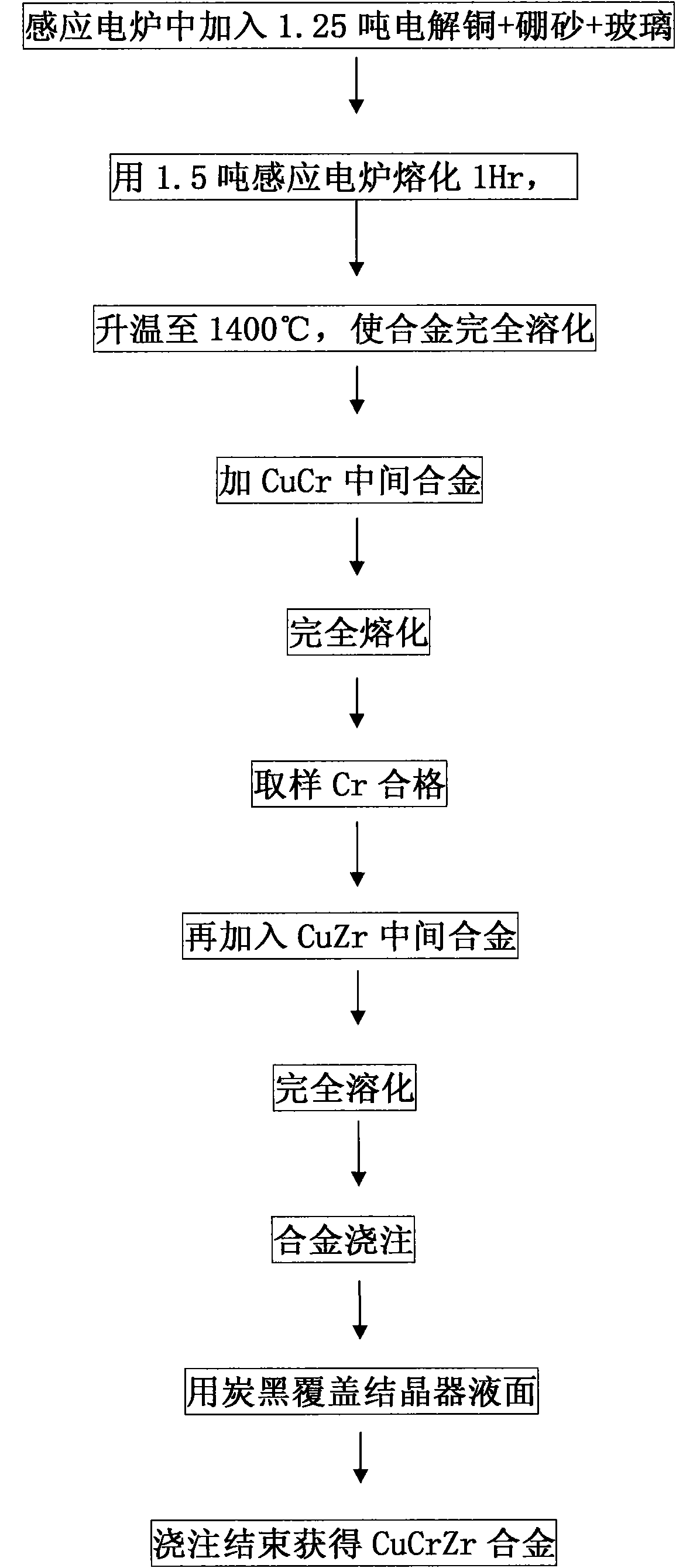

[0016] The non-vacuum smelting process technology of CuCrZr alloy of the present invention is carried out according to the following steps:

[0017] 1) Make CuCr / CuZr intermediate alloys from easily oxidizable elements such as Cr and Zr, and use them as raw materials for subsequent addition.

[0018] 2) Select 1.25 tons of standard cathode copper that meets the quality requirements, add it to a 1.5-ton intermediate frequency induction furnace, and add 12.8 kg of dehydrated borax and glass as a covering agent, wherein the weight ratio of dehydrated borax and glass is set to 2: 1, Melt the electrolytic copper, and cover the copper melt with a covering agent to avoid direct contact with the air; raise the temperature of the molten copper water to about 1400°C, add 28.5kg of CuCr master alloy, melt it, and then The chemical composition of Cr was sampled and analyzed, and the weight ratio of the standard ingredients was set at about 1.0%. After the element sampling was qualified, w...

Embodiment 2

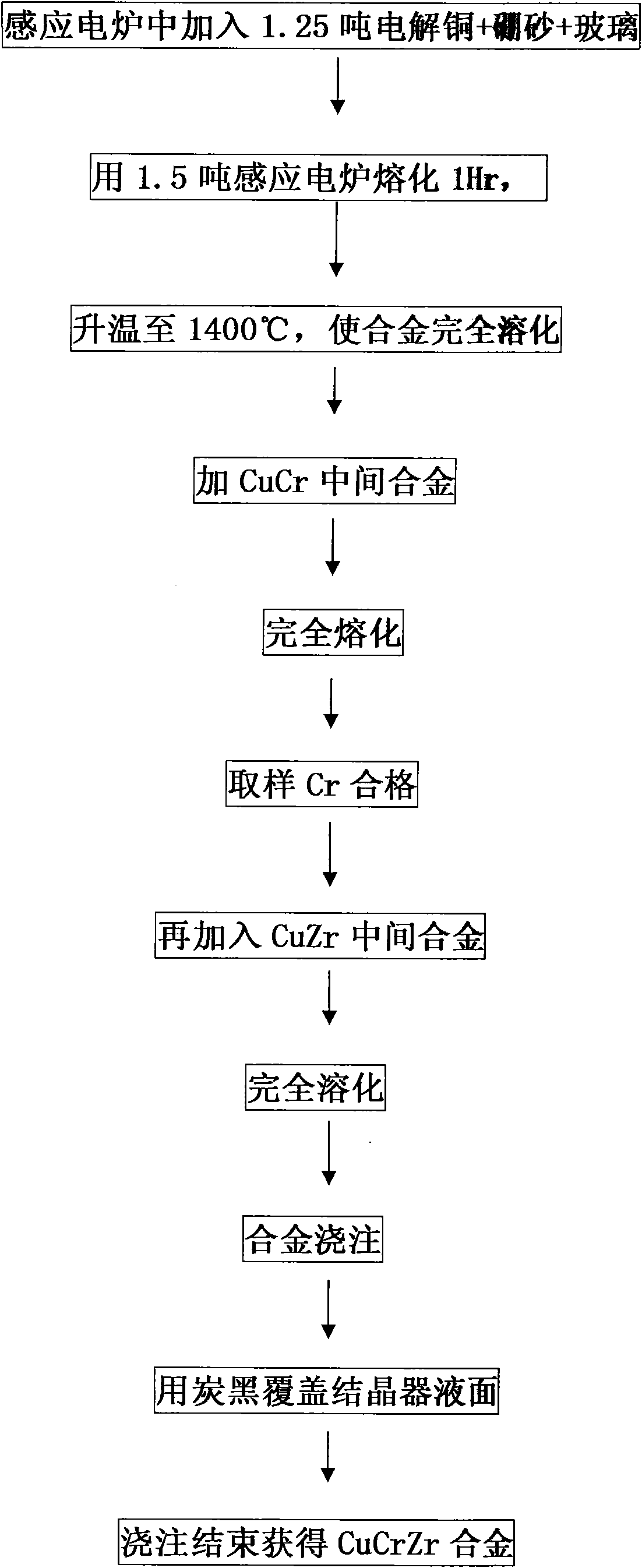

[0020] The non-vacuum smelting process technology of CuCrZr alloy of the present invention is carried out according to the following steps:

[0021] 1) Make CuCr / CuZr intermediate alloys from easily oxidizable elements such as Cr and Zr, and use them as raw materials for subsequent addition.

[0022] 2) Select 1.25 tons of standard cathode copper that meets the quality requirements, add it to a 1.5-ton intermediate frequency induction furnace, and add 12.8 kg of dehydrated borax and glass as a covering agent, wherein the weight ratio of dehydrated borax and glass is set to 2: 1, Melt the electrolytic copper, and cover the copper melt with a covering agent to avoid direct contact with the air; raise the temperature of the molten copper water to about 1400°C, add 25.8kg of CuCr master alloy, melt it, and then The chemical composition of Cr was sampled and analyzed, and the weight ratio of the standard ingredients was set at about 1.0%. After the element sampling was qualified, w...

Embodiment 3

[0024] The non-vacuum smelting process technology of CuCrZr alloy of the present invention is carried out according to the following steps:

[0025] 1) Make CuCr / CuZr intermediate alloys from easily oxidizable elements such as Cr and Zr, and use them as raw materials for subsequent addition.

[0026] 2) Select 1.25 tons of standard cathode copper that meets the quality requirements, and add it to a 1.5-ton medium-frequency induction furnace, and add 14 kg of dehydrated borax and glass as a covering agent, wherein the weight ratio of dehydrated borax and glass is set to 2: 1. The electrolytic copper is melted, and the covering agent is covered on the copper melt to avoid direct contact with the air; the temperature of the molten copper water is raised to about 1400°C, and 29.5kg of CuCr master alloy is added to melt it, and then take a sample The chemical composition of Cr was analyzed, and the weight ratio of the standard ingredients was set at about 1.0%. After the element sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com