Water-proof moisture-permeable polyurethane thermoplasticity elastomer and preparation method thereof

A thermoplastic elastomer, waterproof and moisture-permeable technology, applied in the field of thermoplastic elastomer, can solve the problems of difficult natural degradation, difficult production process, high cost unit price, etc., and achieve the effect of convenient operation and control, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

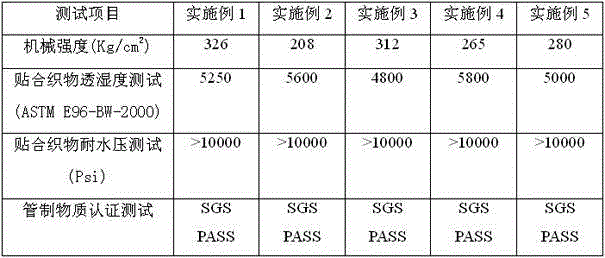

Examples

Embodiment 1

[0041] A waterproof and moisture-permeable polyurethane thermoplastic elastomer, the waterproof and moisture-permeable polyurethane thermoplastic elastomer is made of polyurethane granules, and the polyurethane granules are composed of the following raw materials in parts by weight:

[0042] 50 parts of polyester polyol or polyether polyol

[0043] 40 parts of diisocyanate

[0044] 10 parts of chain extender;

[0045] Among them, polyester polyol is made of polybasic acid and polyol according to the molar ratio of 1:1.01 through dealcoholization and dehydration polycondensation by vacuum melting method. Its hydroxyl value is 20mgKOH / g and acid value is 0.1mgKOH / g.

[0046] The polybasic acid is a mixture of azelaic acid, terephthalic acid and isophthalic acid in a weight ratio of 2:0.5:1.4.

[0047] The polyhydric alcohol is ethylene glycol, 1,3-butanediol, 1,4-butanediol, diethylene glycol, neopentyl glycol, 2-methyl-1,3-propanediol, hexanediol, 3 -Methyl 1,5-pentanediol, ...

Embodiment 2

[0055] A waterproof and moisture-permeable polyurethane thermoplastic elastomer, the waterproof and moisture-permeable polyurethane thermoplastic elastomer is made of polyurethane granules, and the polyurethane granules are composed of the following raw materials in parts by weight:

[0056] 60 parts of polyester polyol or polyether polyol

[0057] 32.5 parts of diisocyanate

[0058] 7.5 parts of chain extender;

[0059] Among them, polyester polyol is made of polybasic acid and polyol according to the molar ratio of 1:1.05 through dealcoholization and dehydration polycondensation by vacuum melting method. Its hydroxyl value is 40mgKOH / g and acid value is 0.5mgKOH / g.

[0060] The polybasic acid is succinic acid, adipic acid, azelaic acid, sebacic acid, terephthalic acid, isophthalic acid or maleic acid.

[0061] Described polyhydric alcohol is made of 1,3-butanediol, 2-methyl-1,3-propanediol, 3-methyl 1,5-pentanediol and 1,4-cyclohexanedimethanol with weight ratio 1: A mixt...

Embodiment 3

[0069] A waterproof and moisture-permeable polyurethane thermoplastic elastomer, the waterproof and moisture-permeable polyurethane thermoplastic elastomer is made of polyurethane granules, and the polyurethane granules are composed of the following raw materials in parts by weight:

[0070] 70 parts of polyester polyol or polyether polyol

[0071] 25 parts of diisocyanate

[0072] 5 parts of chain extender;

[0073] Among them, polyester polyol is made of polybasic acid and polyol according to the molar ratio of 1:1.1 through dealcoholization and dehydration polycondensation by vacuum melting method. Its hydroxyl value is 70mgKOH / g and acid value is 1mgKOH / g.

[0074] The polybasic acid is a mixture of azelaic acid, terephthalic acid and isophthalic acid in a weight ratio of 3:1:1.8.

[0075] Described polyhydric alcohol is made of 1,3-butanediol, 2-methyl-1,3-propanediol, 3-methyl 1,5-pentanediol and 1,4-cyclohexanedimethanol with weight ratio 1: A mixture composed of 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com